Production method of flavor blend oil giving consideration to low oil fume and flavor characteristics, and flavor blend oil prepared by production method

A production method and technology of blending oil, applied in the direction of producing fat, edible oil/fat, and using additives to preserve fatty substances, etc., can solve the problems of high smoke point, inability to take into account flavor and high smoke point characteristics, etc., and achieve favorable Nutritional balance and cost control, rich taste and aroma, avoid monotonous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

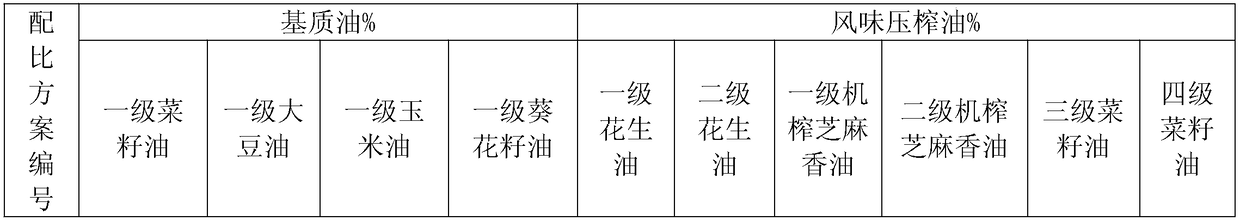

Method used

Image

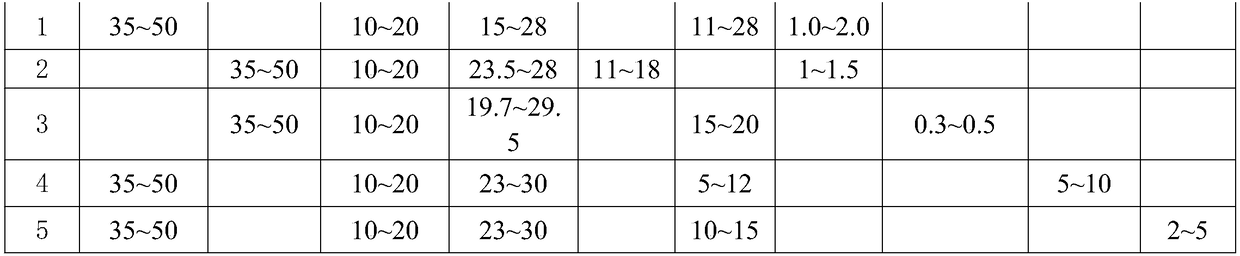

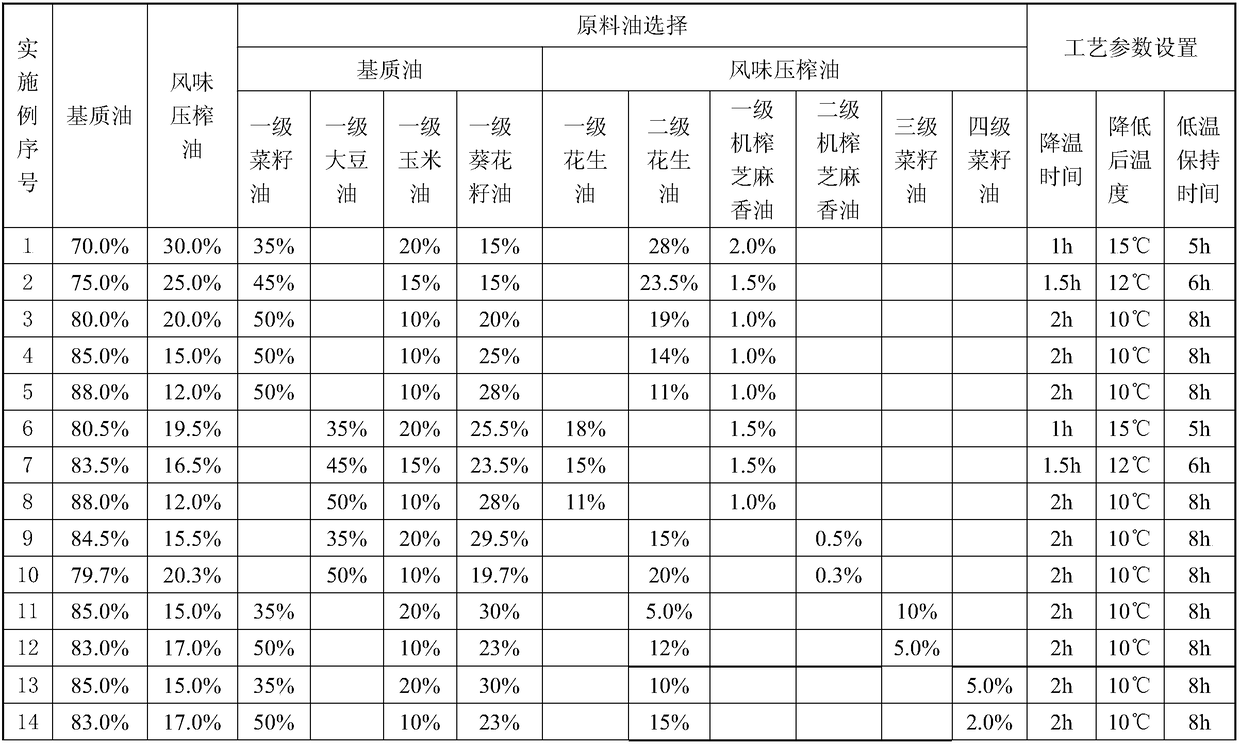

Examples

Embodiment 1

[0053] A method for producing flavored blended oil with both low oil smoke and flavor characteristics, the steps are as follows:

[0054] (1) select raw material oil, its raw material oil is selected by component and the proportioning ratio shown in table 2 embodiment 1; Oxidation value ≤ 1.5mmol / kg, acid value ≤ 0.20mg / g; quality index requirements for peanut oil selected for flavor pressed oil: moisture ≤ 0.10%, insoluble impurities ≤ 0.05%, peroxide value ≤ 2.5mmol / kg, acid value ≤ 0.90mgKOH / g; the quality index requirements of sesame oil selected for flavor pressed oil: moisture ≤0.10%, insoluble impurities ≤0.10%, peroxide value ≤1.0mmol / kg, acid value ≤1.8mgKOH / g;

[0055] (2) Cool the flavored pressed oil to 15°C within 1 hour, keep the low temperature for 5 hours to grow crystals, and then filter through two layers of filter paper to remove crystals;

[0056] (3) Antioxidant adopts tertiary butyl hydroquinone, and its consumption is 0.0125% of the total weight of flav...

Embodiment 2

[0059] A method for producing flavored blended oil with both low oil smoke and flavor characteristics, the steps are as follows:

[0060] (1) select raw material oil, its raw material oil is selected according to the component and the proportioning ratio shown in Table 2 embodiment 2; Wherein, the first grade edible oil quality index requirement that base oil is selected: moisture ≤ 0.05%, insoluble impurity ≤ 0.05% , peroxide value ≤ 1.5mmol / kg, acid value ≤ 0.20mg / g; peanut oil quality index requirements for flavor pressed oil: moisture ≤ 0.10%, insoluble impurities ≤ 0.05%, peroxide value ≤ 2.5mmol / kg, acid Price ≤ 0.90mgKOH / g; The quality index requirements of sesame oil selected for flavor pressed oil: moisture ≤ 0.10%, insoluble impurities ≤ 0.10%, peroxide value ≤ 1.0mmol / kg, acid value ≤ 1.8mgKOH / g;

[0061] (2) Cool the flavored pressed oil to 12°C within 1.5 hours, keep the low temperature for 6 hours for crystal growth, and then filter through two layers of filter p...

Embodiment 3

[0065] A method for producing flavored blended oil with both low oil smoke and flavor characteristics, the steps are as follows:

[0066] (1) Select raw material oil, its raw material oil is selected according to the component and proportioning ratio shown in Table 2 embodiment 3; Wherein, the first grade edible oil quality index requirement that base oil is selected: moisture≤0.05%, insoluble impurity≤0.05% , peroxide value ≤ 1.5mmol / kg, acid value ≤ 0.20mg / g; quality index requirements for peanut oil selected for flavor pressed oil: moisture ≤ 0.15%, insoluble impurities ≤ 0.05%, peroxide value ≤ 2.5mmol / kg, acid Price ≤ 2.0mgKOH / g; Sesame sesame oil quality index requirements for flavor pressed oil: moisture ≤ 0.10%, insoluble impurities ≤ 0.10%, peroxide value ≤ 1.0mmol / kg, acid value ≤ 1.8mgKOH / g;

[0067] (2) Cool the second-grade peanut oil and the first-grade machine-pressed sesame oil to 10°C within 2 hours, maintain the low temperature for 8 hours to grow crystals, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

| smoke point | aaaaa | aaaaa |

| smoke point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com