Automobile air intake end conical shell body and machining method thereof

A technology of air intake end and shell, which is applied in the field of cone shell of automobile air intake end and its processing. It can solve the problems of complex shape, high precision of components, and easy cracking of the connecting parts of two large and small ports, so as to save machining Time, good molding effect, avoid cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]The present invention will be further described below in conjunction with the accompanying drawings.

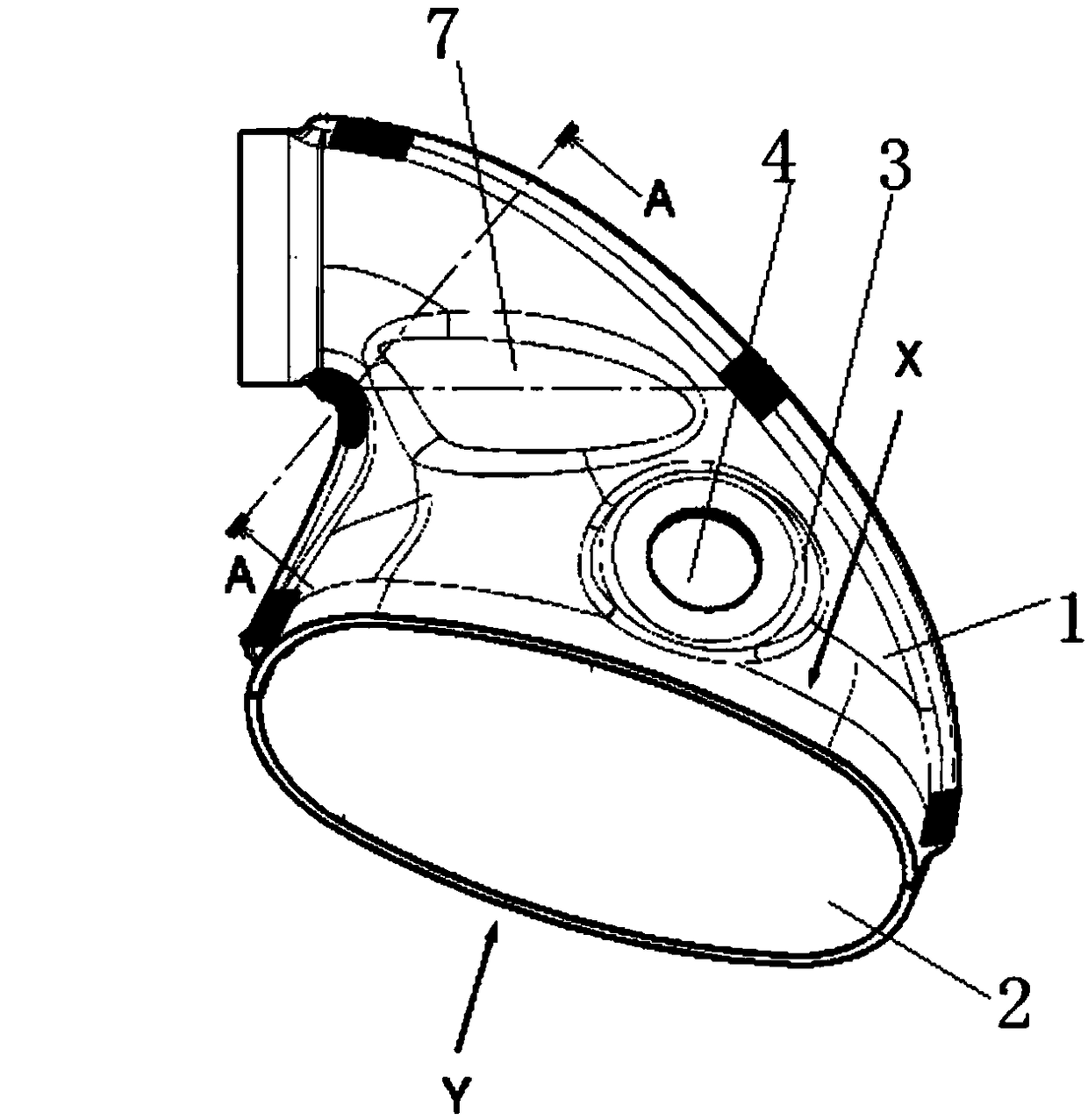

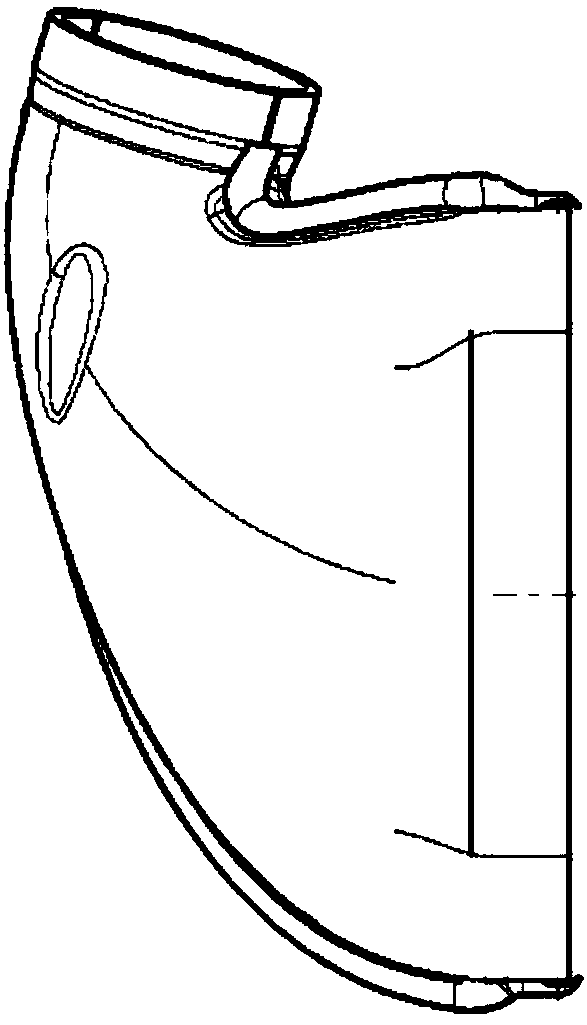

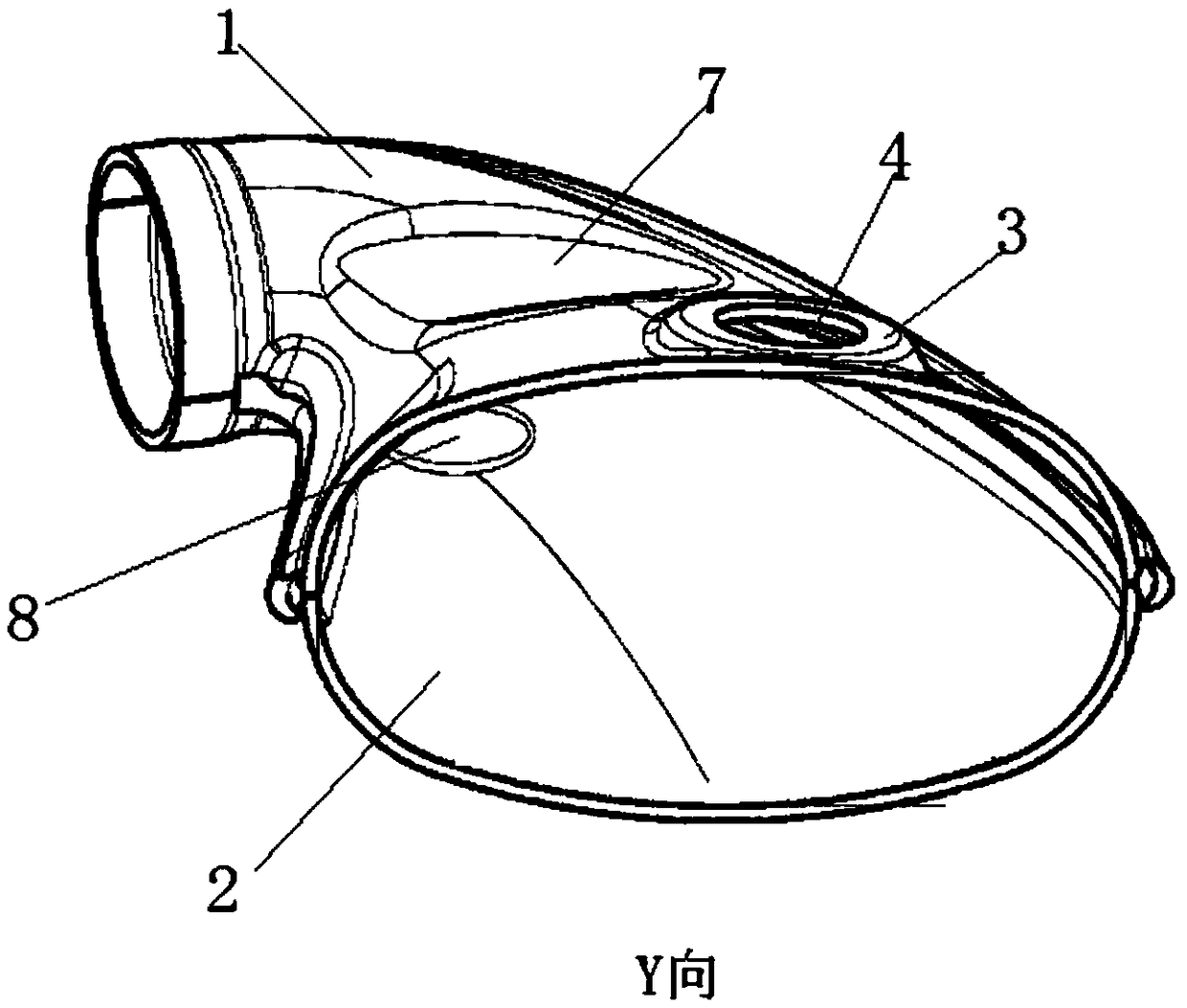

[0054] as attached figure 1 to attach Figure 18 Shown, a kind of cone shell of automobile inlet end is characterized in that: the cone shell of described air intake end is the pipe-shaped structure of cigarette pipe, and the cone shell of described air intake end is irregular curved surface shape, and described The two ends of the conical shell at the intake end are provided with communicating ports, the ports include a small end port and a large end port, and the small end port and the large end port form an airflow channel; the conical shell at the intake end includes a second A pre-catalyzed air half-shell 1 and a second pre-catalyzed air half-shell 2, the first pre-catalyzed air half-shell 1 and the second pre-catalyzed air half-shell 2 are cone shells at the intake end along the airflow passage The two half-shell shells separated in the direction of the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com