Component soldering method

A welding method and component technology, which is applied in the direction of welding equipment, electrical components assembly printed circuit, printed circuit, etc., can solve problems such as complex procedures, affecting solder quality and production efficiency, and poor soldering, so as to simplify the welding process and avoid The effect of poor soldering problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

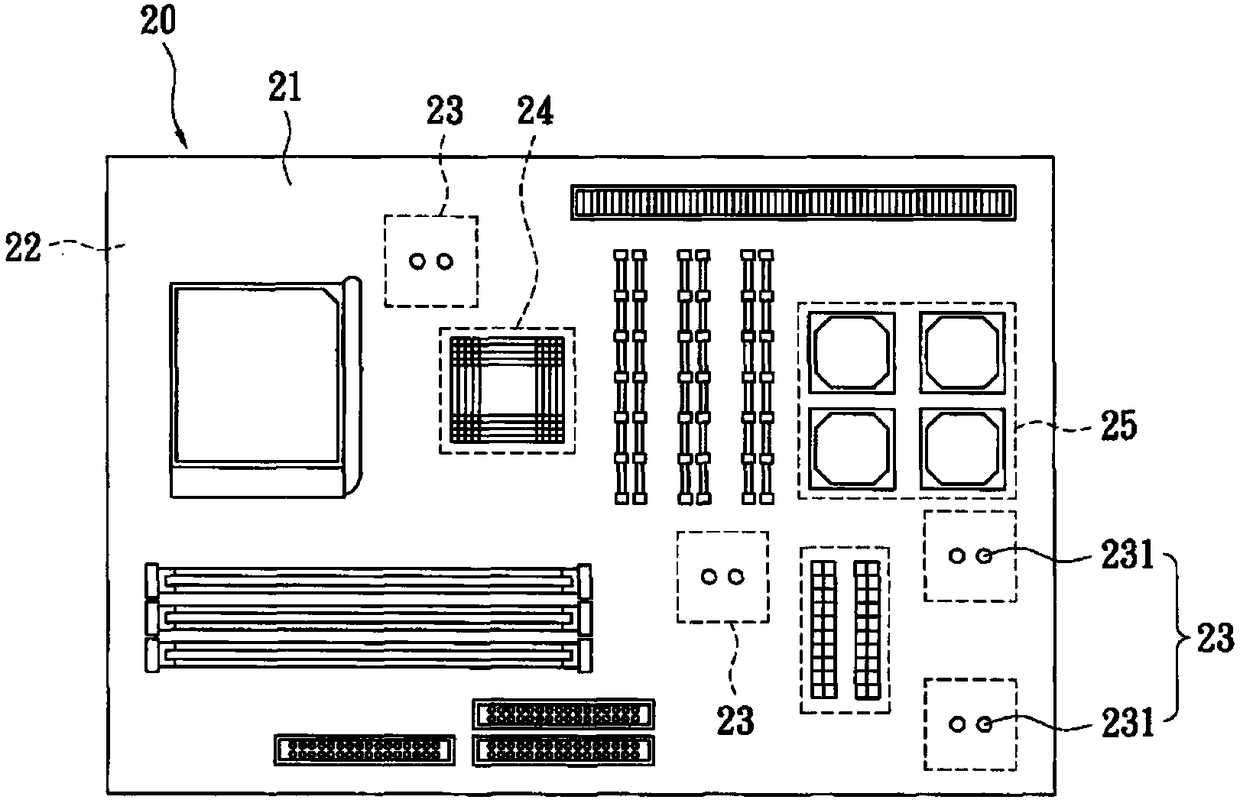

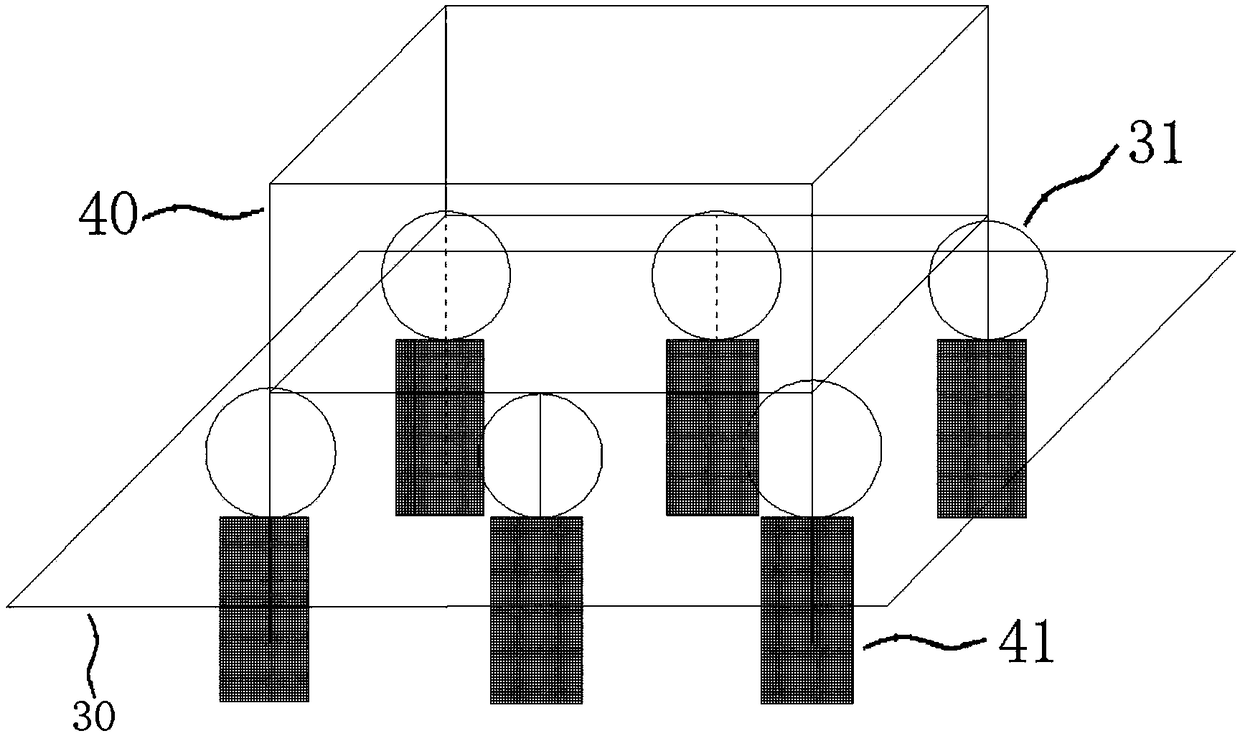

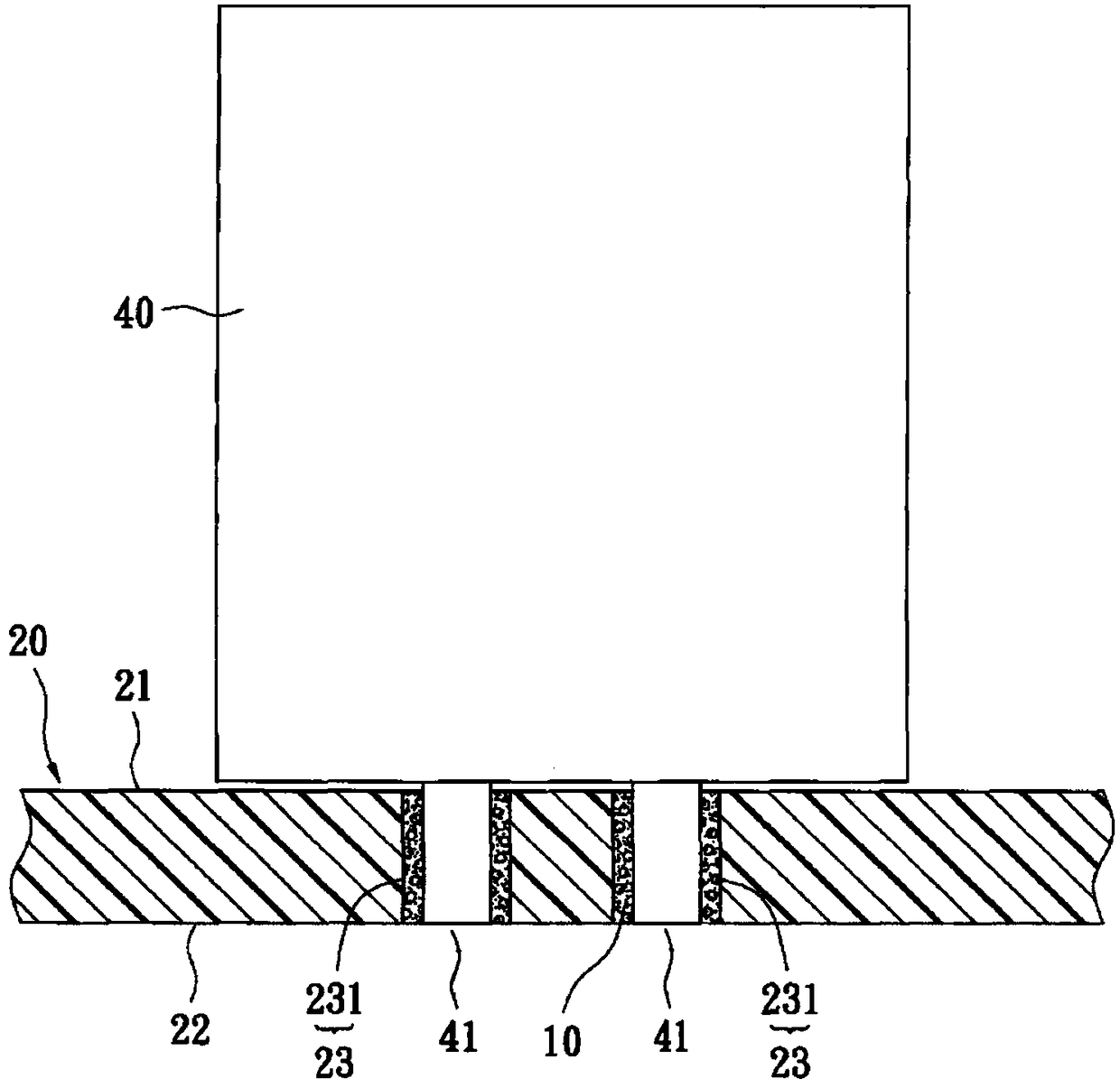

[0033] Next, solder a plurality of pins of at least one plug-in electronic component to a circuit board, and do not need to go through wave soldering equipment during the soldering process. The soldering method includes the following steps:

[0034] Firstly, a thermosetting solder composition is filled into the plurality of pins of the component; then, the plurality of pins of the electronic component are inserted into the plurality of soldering holes, preferably a plurality of soldering holes of the electronic component Before the pins are inserted into the plurality of soldering holes; subsequently, the circuit board carrying the electronic components is placed into a heating device, heated to a reaction temperature so that the solder composition is heated in the heating device and within a reaction time A solder layer is formed by solidification inside, and the plurality of pins contact the solder layer through the plurality of soldering holes to be fixed on the circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com