Novel paster-free 3D printing panel manufactured by using carbon fiber fabric

A carbon fiber fabric and 3D printing technology, which is applied in the field of 3D printing panels, can solve the problems of multiple replacements, achieve good adhesion, prevent movement or swaying, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A new type of sticker-free 3D printing panel made of carbon fiber fabric according to the present invention will be further described below in conjunction with the accompanying drawings.

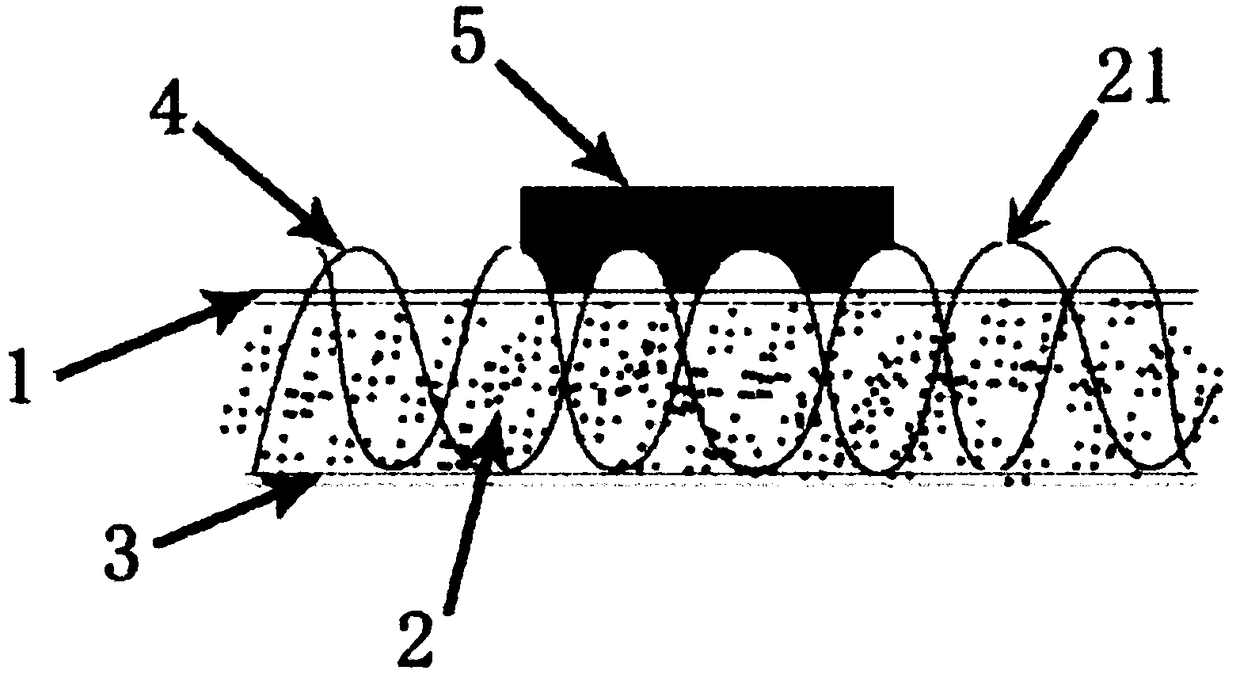

[0009] Such as figure 1 As shown, the new sticker-free 3D printing panel made of carbon fiber fabric in this embodiment is composed of multi-layer materials, including an upper epoxy resin adhesive layer 1, a carbon fiber fabric layer 2 and a lower epoxy resin adhesive layer from top to bottom 3. The fibers 21 of the carbon fiber fabric layer 2 are embedded in the epoxy resin adhesive layer 1 and exposed outside to form a bare fiber layer 4. The exposed fiber layer 4 is the outermost layer of the panel body, and the multi-layer materials are fixed and bonded by the upper and lower epoxy resin adhesive layers. as one.

[0010] The carbon fiber panel of this embodiment has 5% to 15% of the carbon fiber 21 exposed outside. When printing, the printing consumables in the 3D printer will m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com