Dual epoxy end-capping reagent, preparation method thereof, wool raising agent comprising same, and preparation method of wool raising agent

A technology of double epoxy sealing and end-capping agent, applied in the direction of animal fibers, etc., can solve the problems of complicated preparation process, limited processing effect of wool and cashmere fabrics, poor control of reaction process, etc., and achieves simple production process and improved bulkiness. and softening degree, the effect of avoiding the effect of molecular branching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

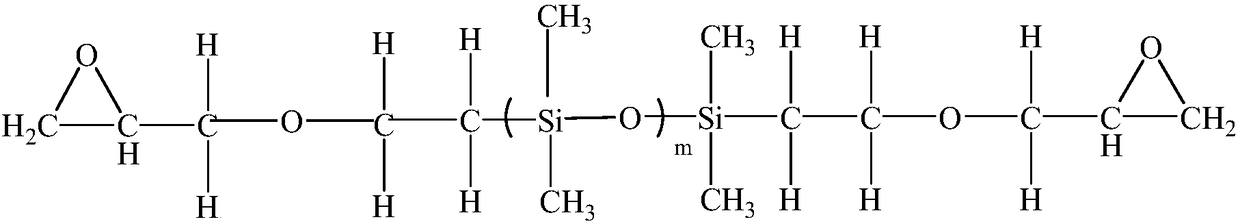

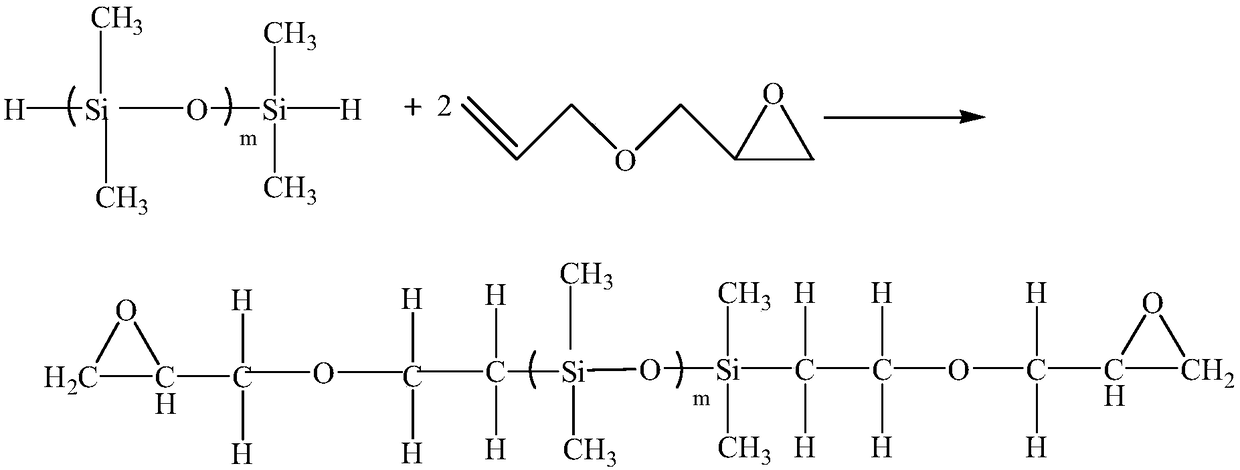

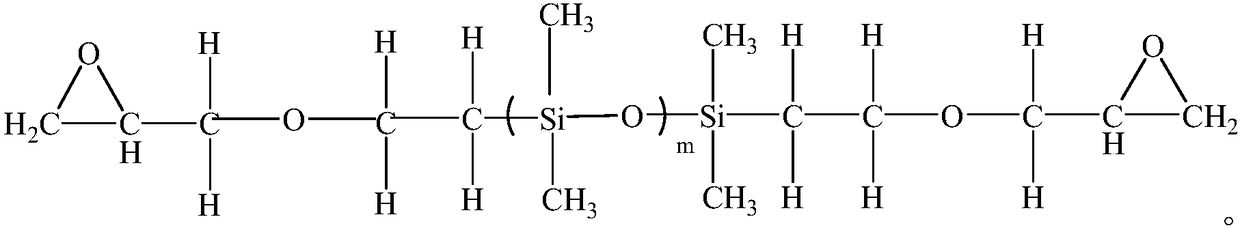

[0019] A preparation method of a diepoxy end-capping agent: Step 1. Add 814Kg of low-end hydrogen-containing silicone oil with a molecular weight of 1000 and 186Kg of allyl glycidyl ether into an enamel reaction kettle, heat to 70°C, and stir evenly; Step 2: Add 6g of chloroplatinic acid, seal the reaction kettle, and keep it warm at 70°C for 4 hours; Step 3: Vacuumize the reaction kettle for 30 minutes, cool down the reaction kettle with circulating cooling water, cool down to 35°C and discharge to obtain the product double Epoxy capping agent 1000Kg. The reaction principle is: under the catalysis of the catalyst chloroplatinic acid, the low-end hydrogen-containing silicone oil reacts with the coupling agent allyl glycidyl ether to form the diepoxy end-capping agent of the present invention.

Embodiment 2

[0021] A wool leavening agent includes a double epoxy end-capping agent. The wool leavening agent is prepared in the following way: 940Kg of octamethylcyclotetrasiloxane, 60Kg of diepoxy end-capping agent, and 600g of tetramethylammonium hydroxide are reacted in a closed reaction kettle at 90°C 1 hour, then raise the temperature to 110°C for 2 hours, then raise the temperature to 140°C for 1 hour, then vacuum for 30 minutes, add 72Kg of polyetheramine and 715Kg of ethylene glycol butyl ether after the temperature drops to 100°C, and heat up to 135°C After the insulation for 6 hours, finally cool to 35°C and discharge to obtain 1787Kg wool leavening agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com