A high viscoelastic joint filling material for acid aggregate asphalt pavement and preparation method thereof

A technology for asphalt pavement and joint filling materials, which is applied in the direction of asphalt material adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., and can solve the problems of poor expansion and contraction performance, re-cracking, and extrusion resistance of joint filling materials Poor pressure performance and other problems, to achieve the effect of preventing re-cracking, expanding the scope of use, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

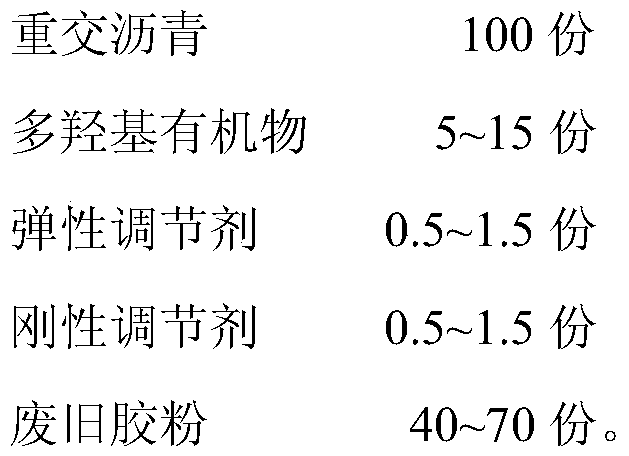

Method used

Image

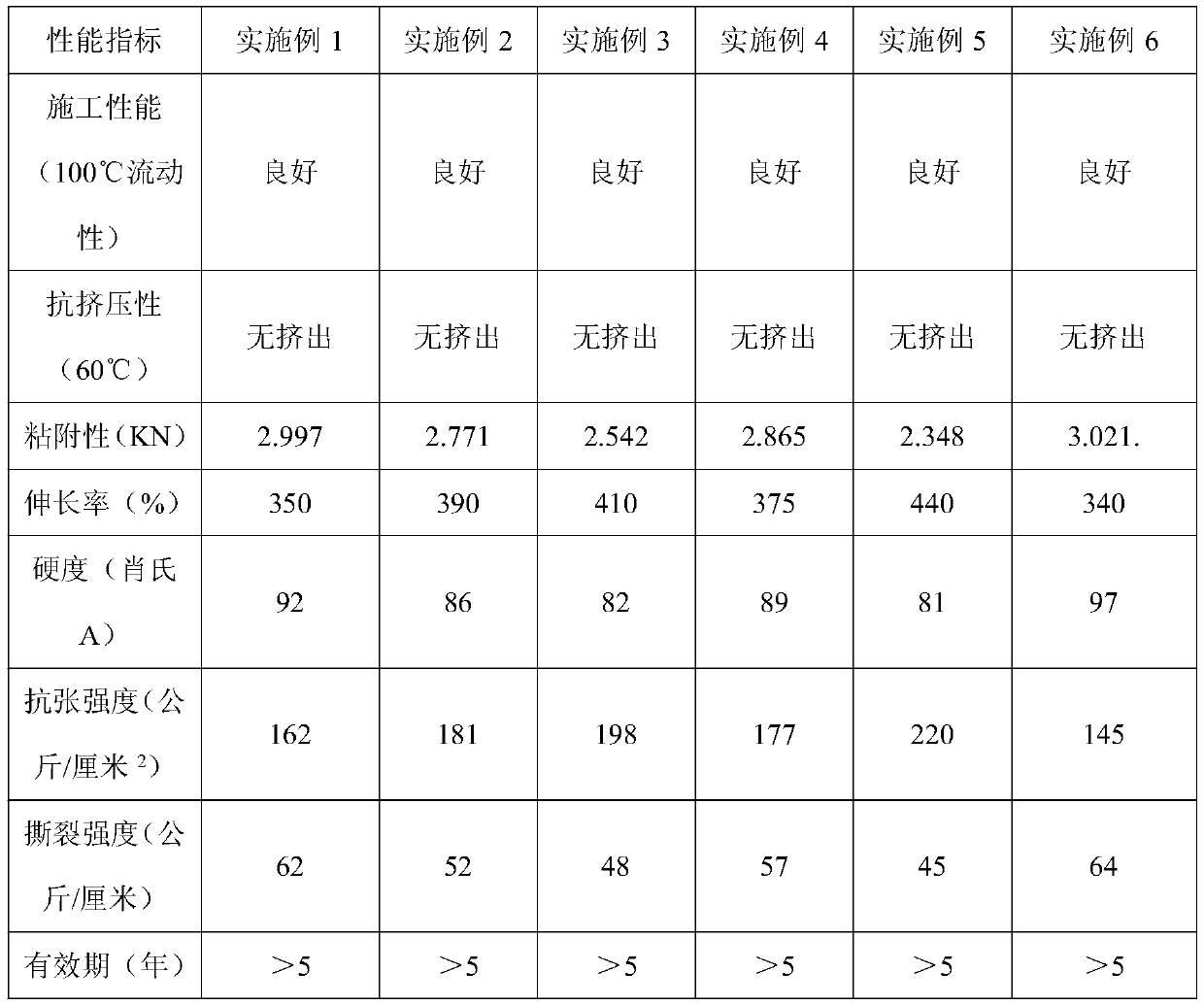

Examples

Embodiment 1

[0026] Select 100 parts of heavy traffic road asphalt AH-50 and heat it to a fluid state at 100°C, add 70 parts of waste rubber powder (4 mesh), 5 parts of hydroxyl-terminated polybutadiene rubber compounds (molecular weight 3300 , functionality 2.2), 0.5 parts of elasticity modifier (4,4`-isopropylidene bisphenol) and 0.5 parts of rigidity modifier (1,5-naphthalene diisocyanate); after mixing, stir for 30 minutes and heat up to 145 under the condition of ℃ for 30min; under the condition of lowering the temperature to 100℃ and then stirring for 30min, the preparation is completed.

Embodiment 2

[0028] Select 100 parts of heavy traffic road asphalt AH-50 and heat it to a fluid state at 110°C, add 40 parts of waste rubber powder (4 mesh), 15 parts of hydroxyl-terminated polybutadiene rubber compounds (molecular weight 4400 , functionality 2.2) and 1.5 parts of elasticity modifier (1,4-butanediol) and 0.5 parts of rigidity modifier (1,4-cyclohexyl diisocyanate); after mixing, stir for 25 minutes and heat up to 145°C Shearing for 25 minutes; cooling down to 100°C and stirring for another 30 minutes to complete the preparation.

Embodiment 3

[0030] 100 parts of heavy traffic road asphalt AH-70 was selected and heated to a fluid state at 100°C, and 50 parts of waste rubber powder (8 mesh), 10 parts of hydroxyl-terminated polybutadiene rubber compounds (molecular weight 3600 , functionality 2.4) and 0.5 parts of elasticity modifier (1,4-butanediol) and 1.0 parts of rigidity modifier (1,4-cyclohexyl diisocyanate); after mixing, stir for 20 minutes and heat up to 145°C Shear for 20 minutes; cool down to 100°C and stir for another 30 minutes to complete the preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com