Novel slurry recycling system for bored pile construction on underwater platform

A technology of circulation system and bored pile, which is applied in construction and other directions, can solve the problems that the mud cannot meet the environmental protection requirements, and achieve the effect of saving the space of the construction platform, reducing the construction cost, and reducing the time for cleaning holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

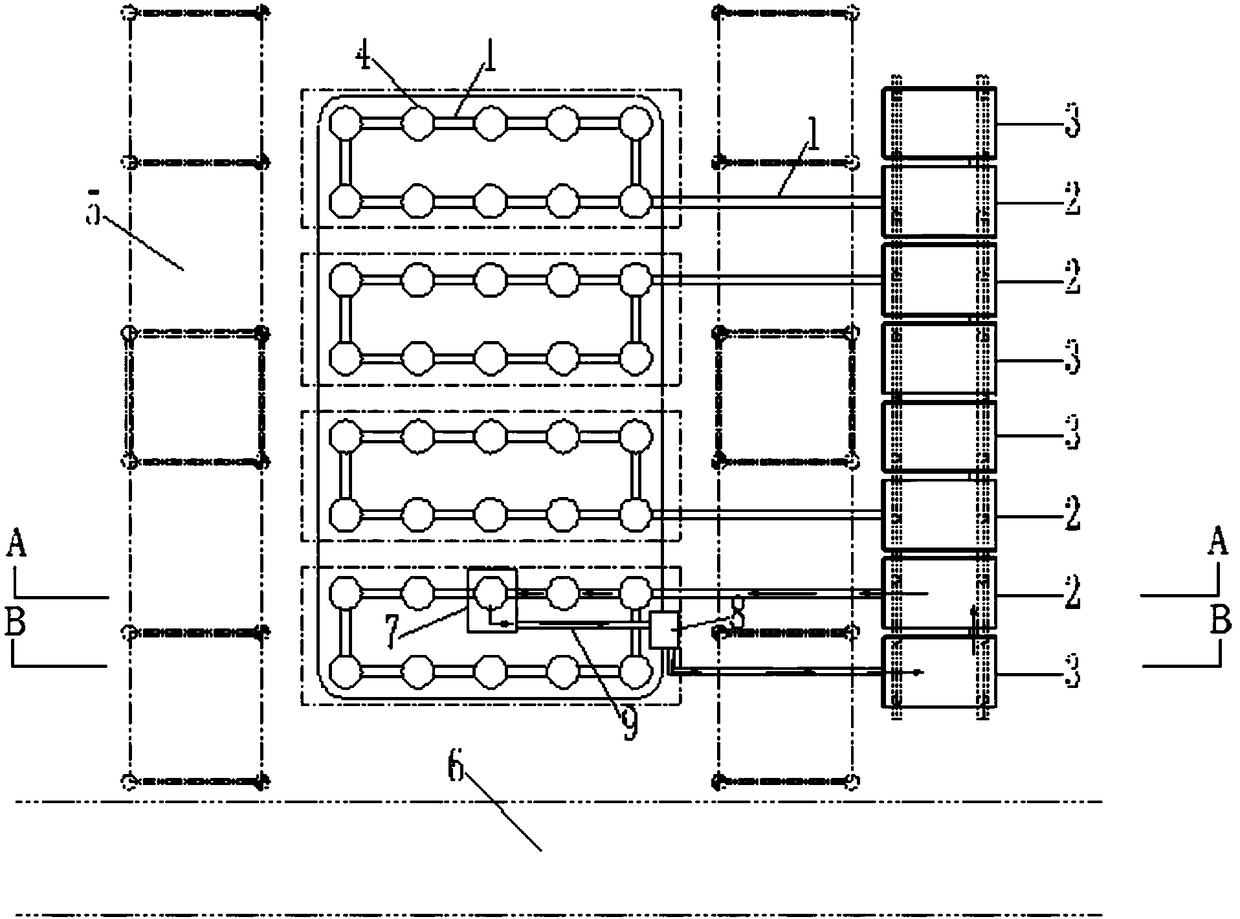

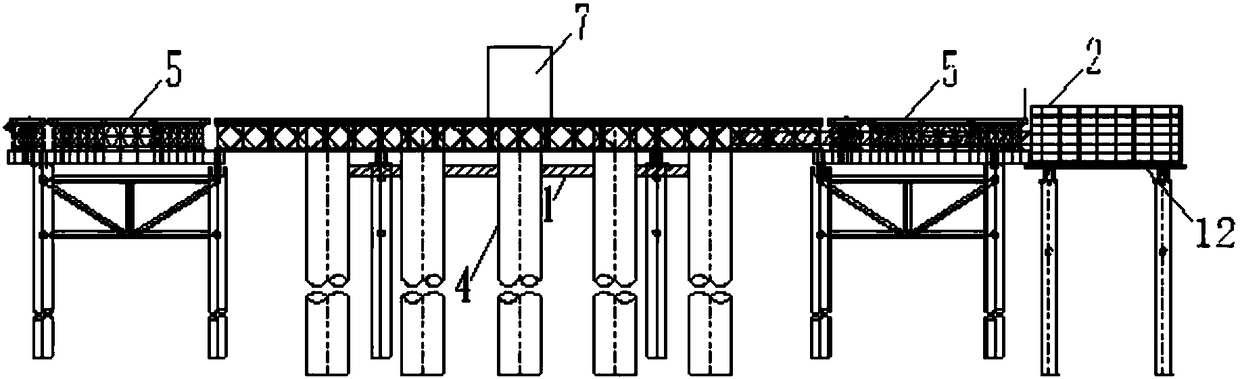

[0015] Specific embodiment 1: This embodiment is a new type of mud circulation system for construction of bored piles on underwater platforms, which includes 4 sets of mud circulation systems, two branch trestles 5 and main trestle 6;

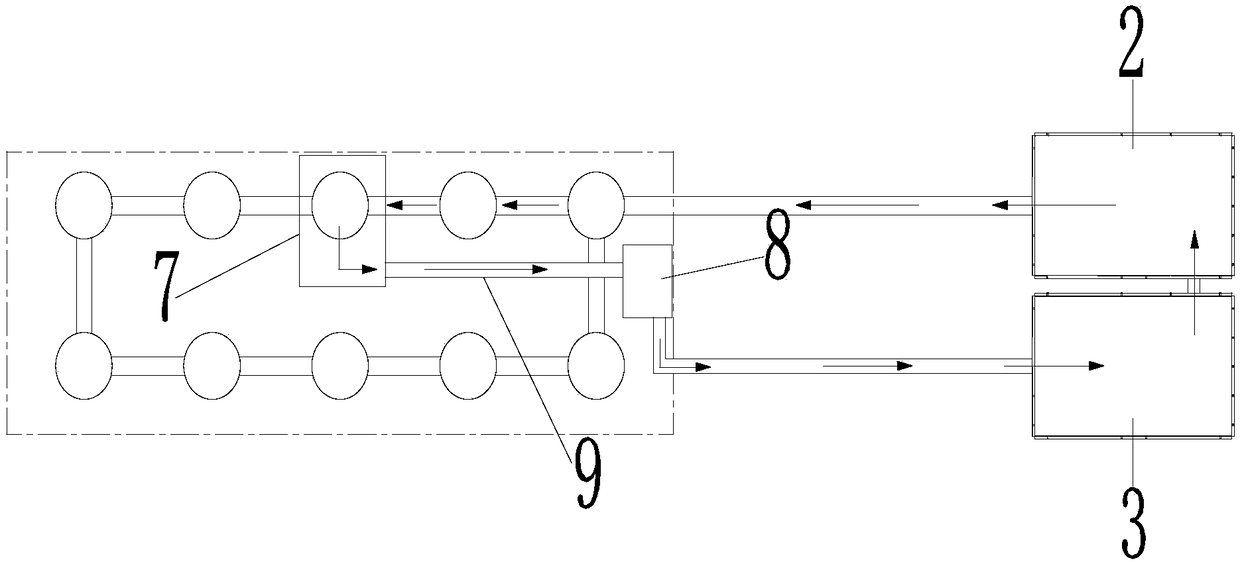

[0016] Each group of mud circulation system includes mud circulation pipeline 1, mud pool 2, sediment tank 3, 10 steel casings 4, gas lift reverse circulation drilling rig 7, mud separator 8, external hose 9 and mud pool platform 12, using The mud circulation pipeline 1 connects 10 steel casings 4 in series to form a closed loop, and uses the mud circulation pipeline 1 to connect one of the 10 steel casings 4 with the mud pool 2; For construction, the air-lift reverse circulation drilling rig 7 is installed above the bored piles for construction, and the drilling slag drilled by the air-lift reverse circulation drilling rig 7 on the bored piles is discharged to the sediment tank through the external hose 9 and the mud separator 8 in sequence In...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mud circulation pipeline 1 is a rectangular pipeline of 75cm×50cm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mud circulation pipeline 1 is welded into a 75cm×50cm rectangular pipeline with a 3mm thick steel plate, and the peripheral edges of the rectangular pipeline are welded with ∠75mm Angle steel for reinforcement. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com