Ammonia and urea dual injection system and control method thereof

A technology of injection system and urea nozzle, which is applied in the direction of electronic control, exhaust treatment, and exhaust device of exhaust gas treatment device, can solve the problems of crystal blockage and low conversion efficiency, and achieve the effect of solving the inconvenience of popularization and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

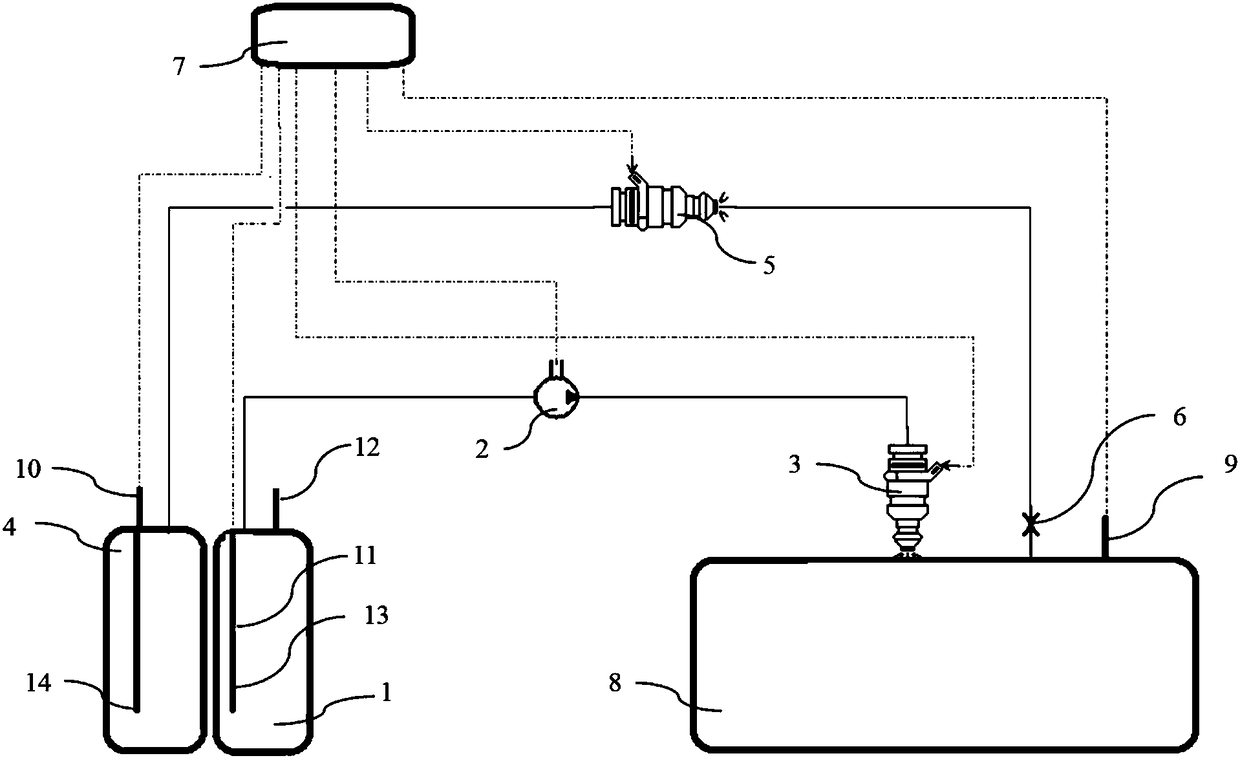

[0030] This embodiment provides an ammonia urea dual injection system, which includes a urea tank 1, a urea pump 2, a urea nozzle 3, an ammonia storage tank 4, an ammonia metering valve 5, an ammonia nozzle 6, an ECU 7, and a post-processor 8. Exhaust temperature sensor 9, ambient temperature sensor 10, urea temperature sensor 11, urea heating water valve 12, urea liquid level sensor 13 and ammonia storage tank heater 14.

[0031] The urea tank 1 stores standard urea solution for vehicles, and the urea pump 2 pumps the urea solution to the urea nozzle 3, and the ECU 7 controls the urea nozzle 3 to spray the atomized urea solution into the post-processor 8 for reaction.

[0032] That is, the inlet of the urea pump 2 communicates with the urea tank 1, the outlet of the urea pump is connected to the urea nozzle 3, and the urea nozzle 3 is installed on the post-processor 8 for backward The urea solution is sprayed in the processor 8 .

[0033] The ammonia storage tank 4 stores li...

Embodiment 2

[0040] This embodiment provides a control method for an ammonia urea dual-injection system, including:

[0041] S10. Detect the temperature of the gas inside the afterprocessor 8 through the exhaust temperature sensor 7. When the temperature of the gas inside the afterprocessor 8 is lower than a certain threshold (200° C.), the ECU 7 controls the ammonia storage tank heater 14 to turn on the The ammonia storage tank 4 is heated and controls the ammonia gas metering valve 5 to measure and inject ammonia gas.

[0042] When the vehicle is cold started, the temperature in the afterprocessor 8 is relatively low. At this time, if urea is sprayed, crystallization and low conversion efficiency are likely to occur. The ammonia gas metering valve 5 is controlled by the ECU 7 to inject the ammonia gas, and the nitrogen oxide emission of the diesel vehicle can be reduced by the ammonia gas.

[0043] S20. When the temperature of the urea solution stored in the urea tank 1 is higher than -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com