Device and method for moving and rotating microsphere object

An object and spherical technology, applied in the field of devices for moving and rotating tiny spherical objects, can solve the problems of damage to tiny spherical objects, complexity of motion control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

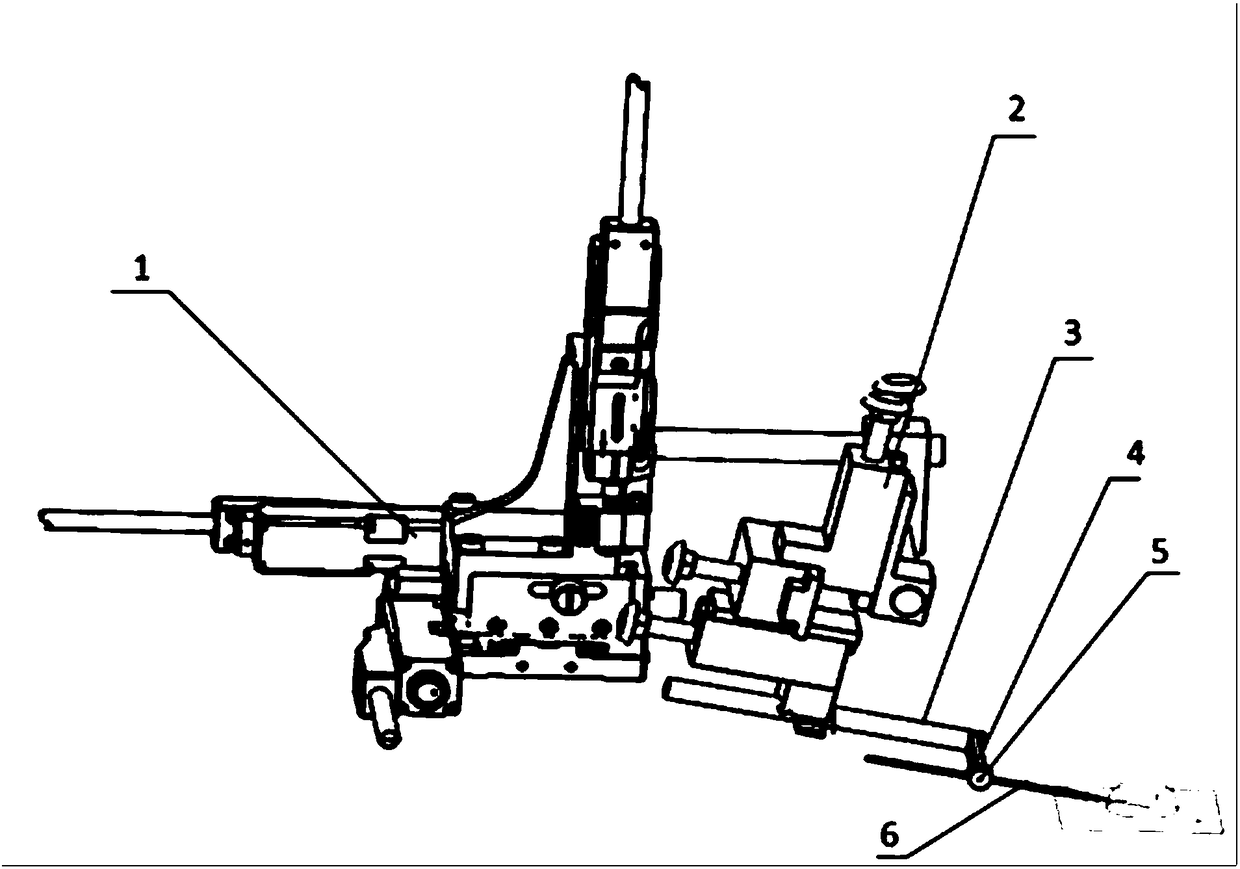

[0036] see figure 1 , which is a structural schematic diagram of a device for moving and rotating tiny spherical objects provided by the embodiment of the present application.

[0037] A device for moving and rotating tiny spherical objects, including a three-coordinate operating platform 1, a manual platform 2, a metal rod 3, a vibration mechanism 4, a metal connector 5, and a glass needle 6; the manual platform 2 is fixed on the three-coordinate On the operating platform 1, the three-coordinate operating platform 1 is used to adjust the position of the manual platform 2; one end of the metal rod 3 is fixed on the manual platform 2, and the other end is vertically connected with the vibration mechanism 4; the glass needle 6 is connected by a metal The part 5 is vertically connected with the end of the vibrating mechanism 4 away from the metal rod 3 , and the tip of the glass needle 6 is placed in the water drop 7 .

[0038] It should be noted that the three-coordinate operat...

Embodiment 2

[0050] Based on the above embodiments, the embodiment of the present application provides a method for moving and rotating a tiny spherical object. see Figure 4 , which is a flow chart of a method for moving and rotating a tiny spherical object provided by the embodiment of the present application.

[0051] A method for moving and rotating a tiny spherical object, applied to a device for moving and rotating a tiny spherical object, the device includes a three-coordinate operating platform 1, a manual platform 2, a metal rod 3, a vibration mechanism 4 and Glass needle 6, comprising the following steps:

[0052] S401: Put the tiny spherical object 8 into the water drop 7, and place the water drop 7 containing the tiny spherical object 8 in the field of view of the microscope through the glass slide 9;

[0053] S402: Adjust the manual platform 2, put the tip of the glass needle 6 into the water drop 7, wherein the tip does not touch the tiny spherical object 8;

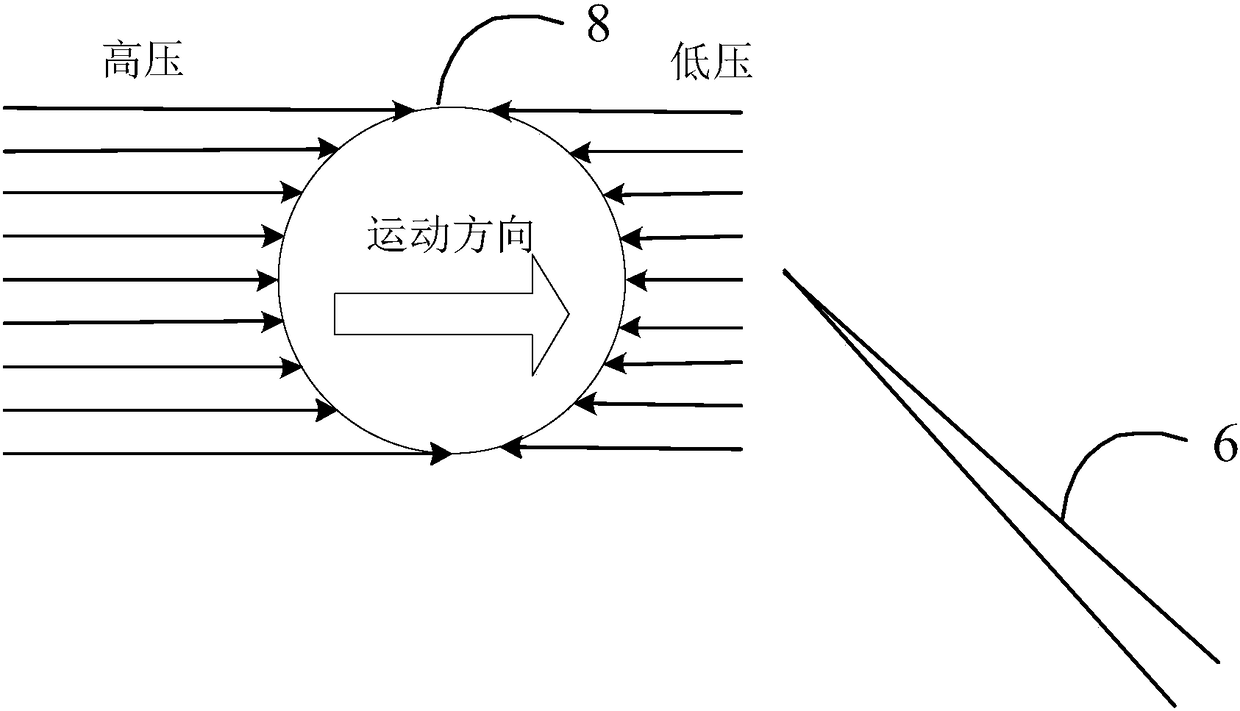

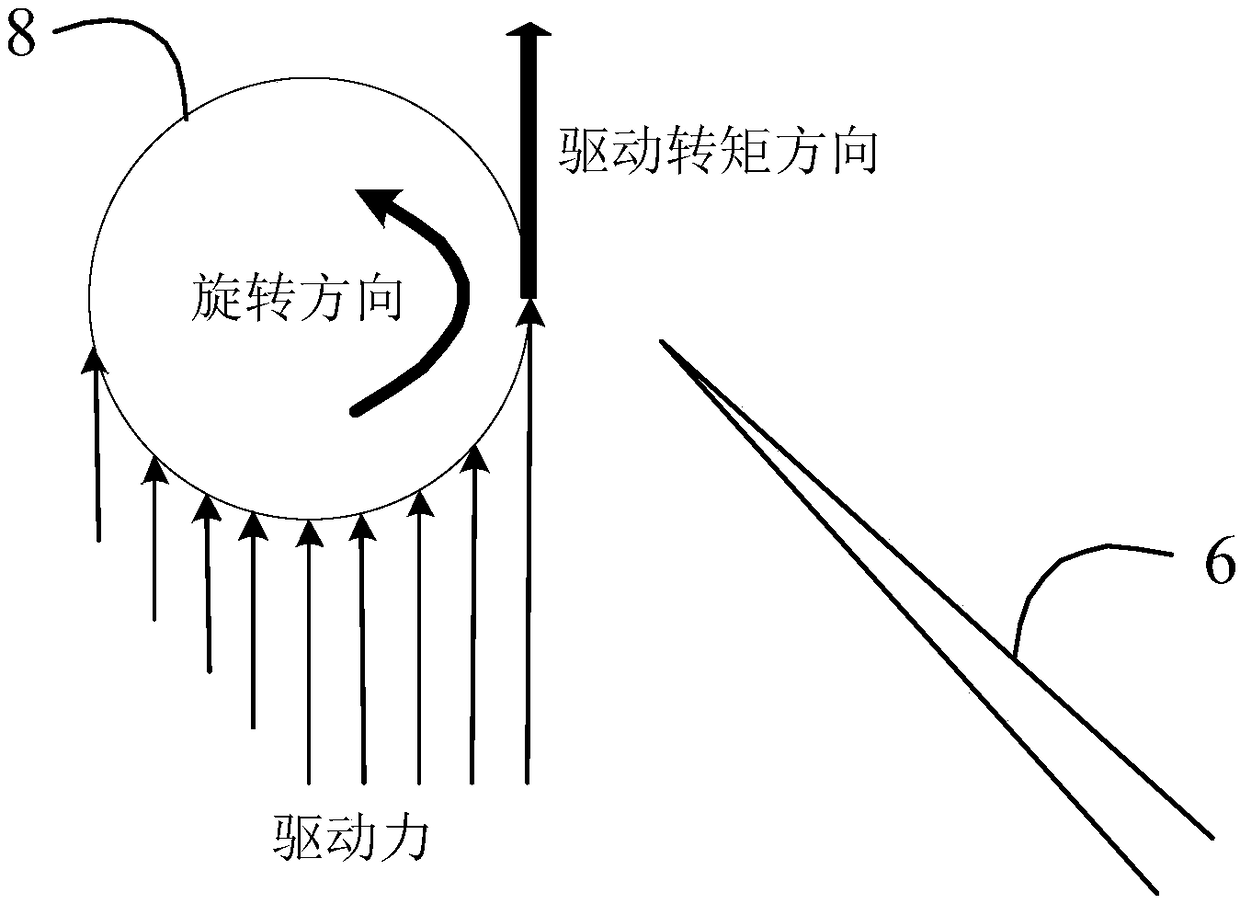

[0054] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com