Transplanting clutching handle automatic gear shifting device of unmanned rice seedling transplanting machine and control method of transplanting clutching handle automatic gear shifting device

An unmanned, automatic gear shifting technology, applied in planting methods, transplanting machinery, agricultural machinery, etc., can solve the problems of unmanned rice transplanter deviation, inability to accurately control gear movement, etc., and achieve a stable and reliable design structure , easy disassembly, large corner movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

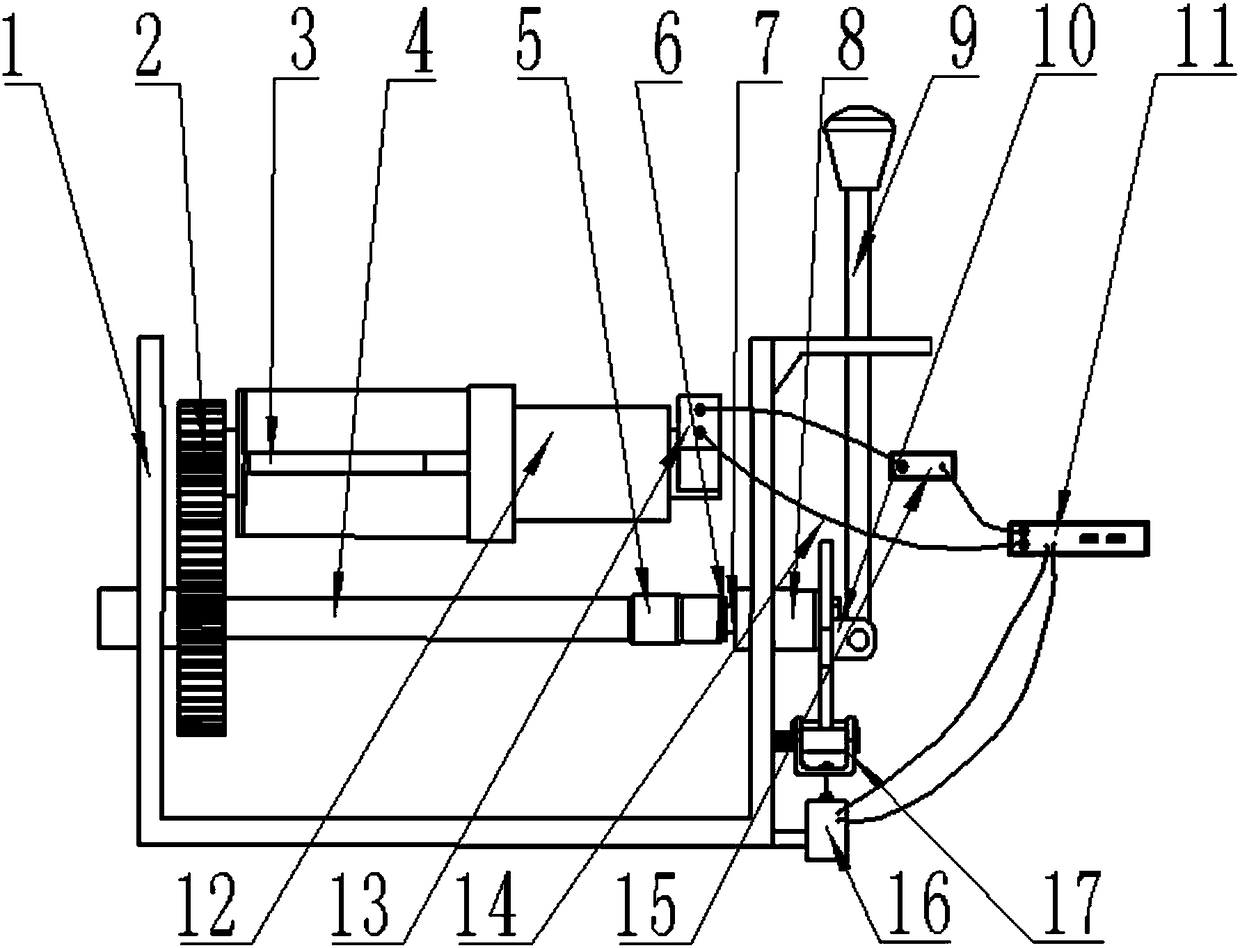

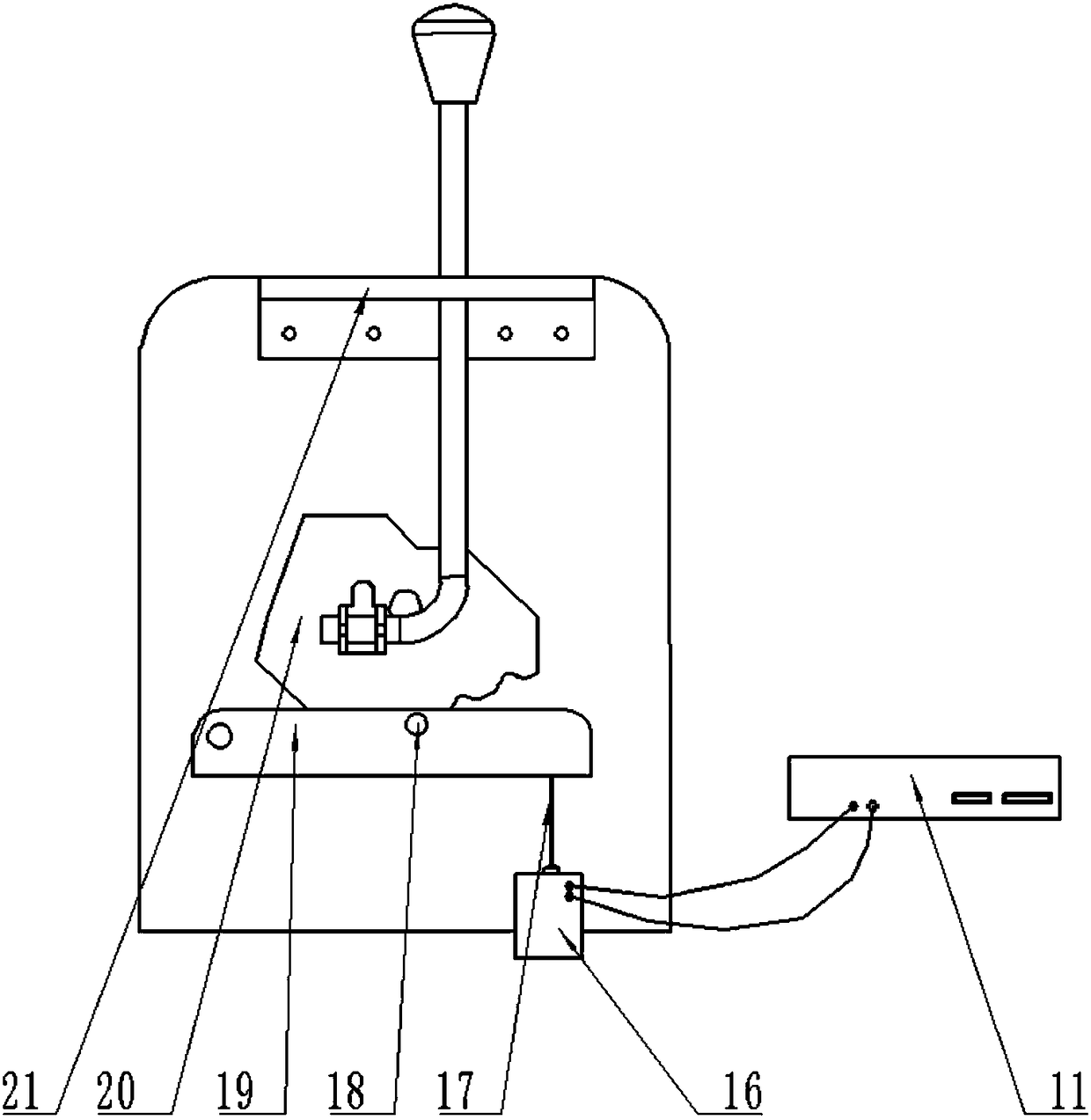

[0035] See attached picture.

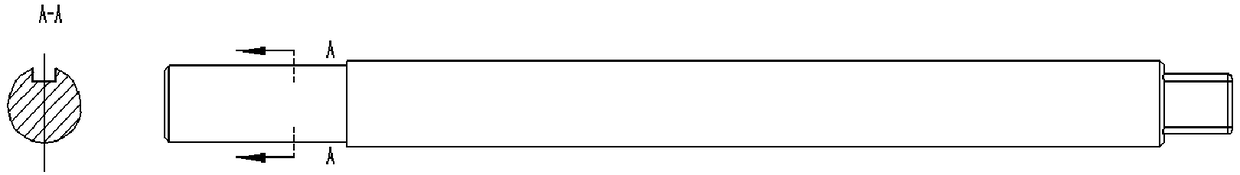

[0036] An automatic shifting device for planting clutch handles of an unmanned rice transplanter, including a longitudinal drive device and a support frame, and the shift drive device includes a controller 11, an encoder 13, a driver 15, a servo motor 12, and a reducer 3 , a pair of spur gears 2, rotating shaft 4, sleeve 5, described controller 11, encoder 13, driver 15 are connected by cable 14, encoder 15 is installed in the tail end of servo motor, and servo motor shaft passes flat key and deceleration The output shaft of the reducer is connected with the driving spur gear 2 through a flat key, the driving spur gear meshes with the driven spur gear, and the driven spur gear is connected with the rotating shaft 4 installed at the lower part of the rice transplanter seat through a key, and the rotating shaft is connected to The sleeve 5 is matched with the nut 6 inserted into one end of the shift support rod 7 of the clutch handle. The longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com