Endothelium peeling system and method for chestnut shell removal production line

A production line and technology for chestnut, applied in the field of the inner skin peeling system of the chestnut shelling production line, can solve the problems of inability to clean the inner skin of the chestnut, the inner skin of the chestnut is difficult to peel off, affecting the taste of the chestnut, etc., so as to prevent dislocation, ensure the cooking effect, improve the effect of taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

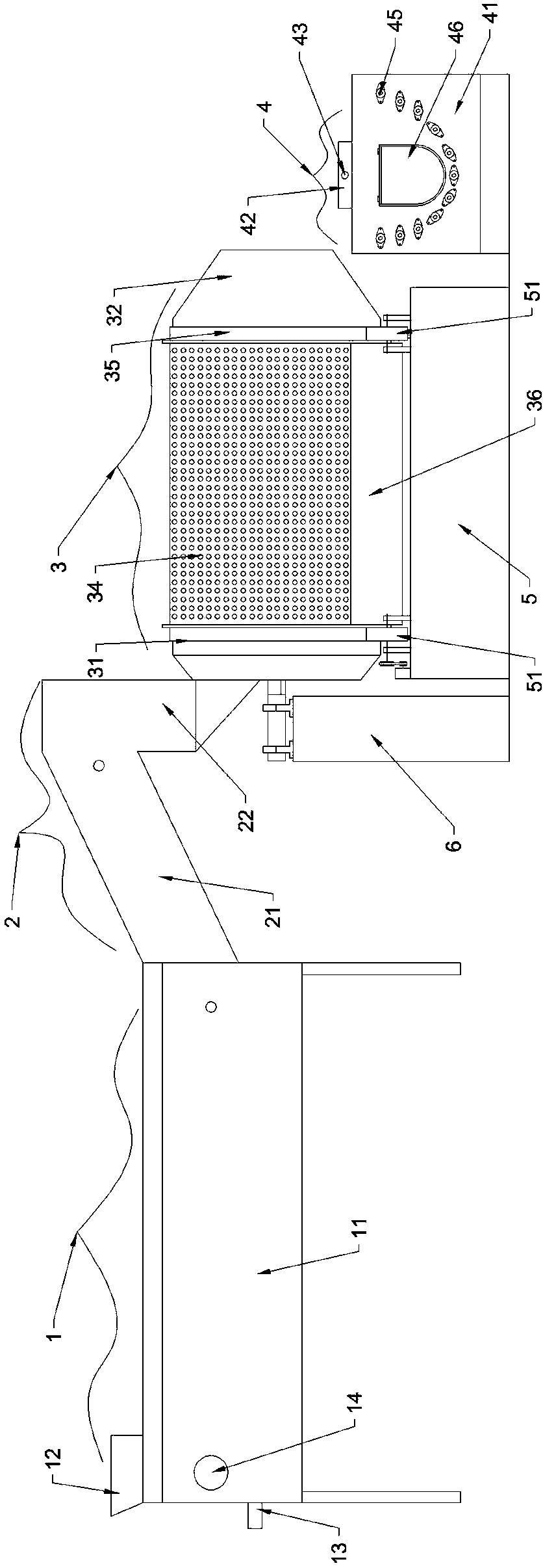

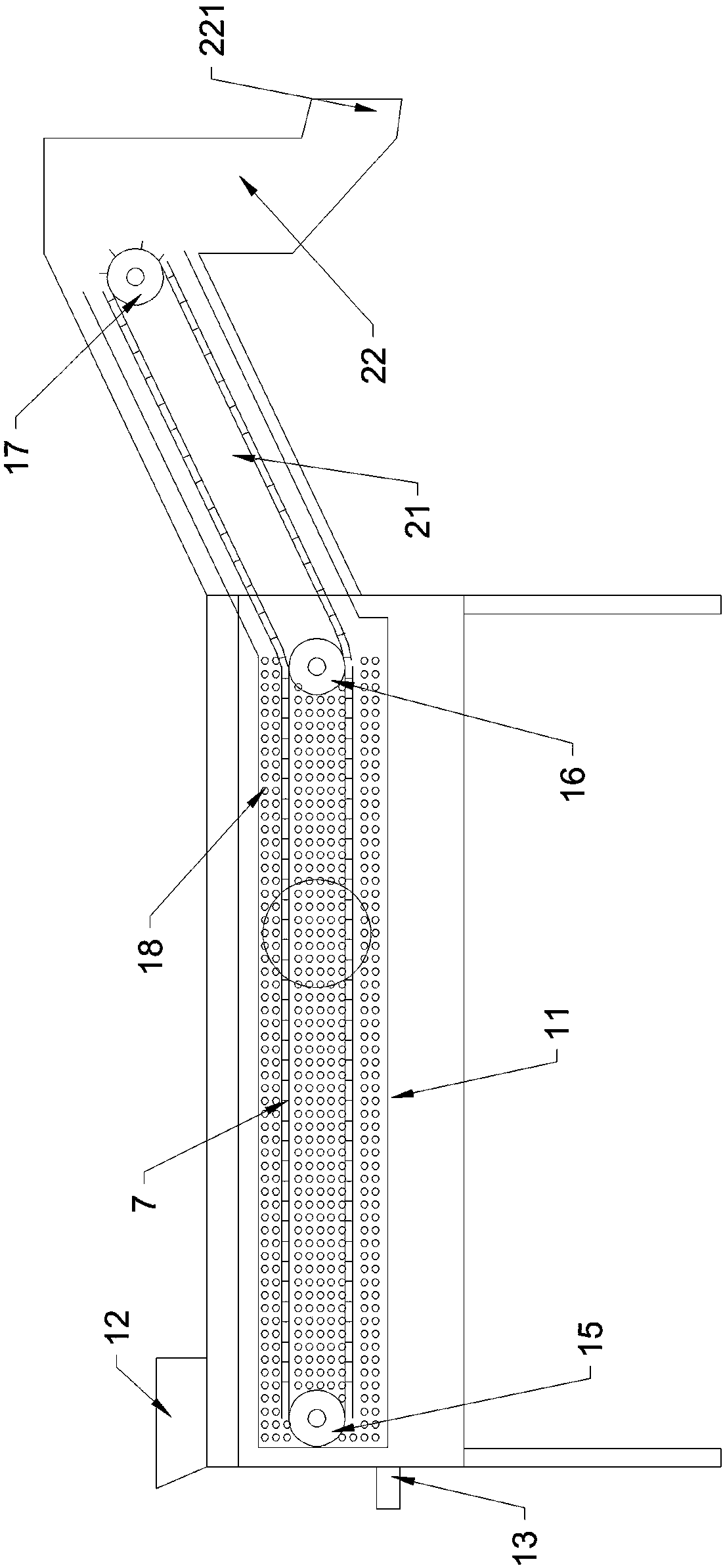

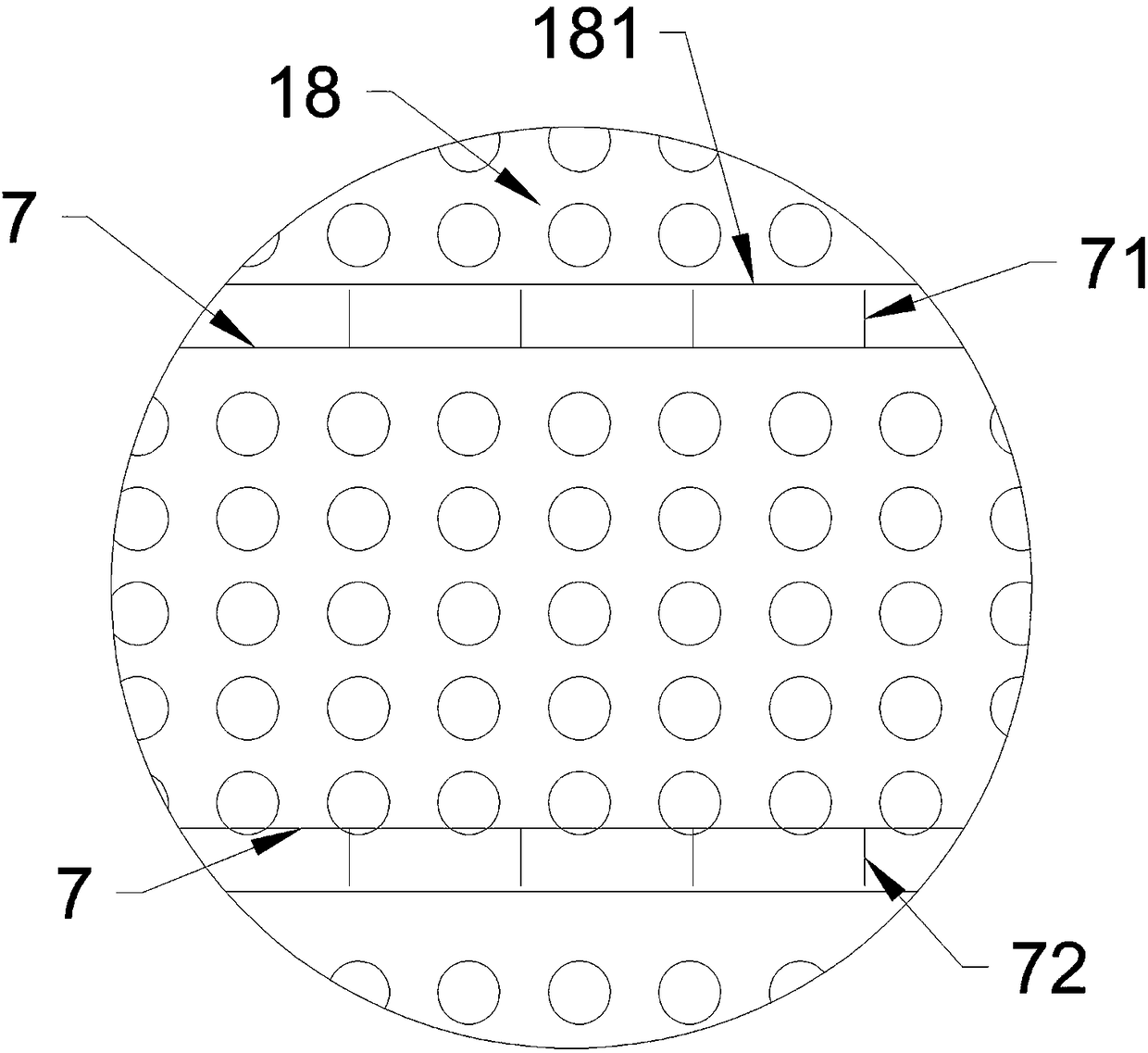

[0029] The specific embodiment of the present invention sees Figure 1-6 :

[0030] An inner skin peeling system used in a chestnut shelling production line includes a cooking mechanism, a conveying pipeline and a peeling mechanism connected in sequence. The cooking mechanism includes a hot water tank placed on the ground with the same legs. The top of the hot water tank is one end There is a flip cover with a feed inlet, and the hot water tank is provided with a conveying mesh belt whose tail end extends into the conveying pipeline. The surface of the conveying mesh belt is provided with a material plate. It is a vertical filter plate fixed on the inner wall of the hot water tank. The bottom of the hot water tank is provided with a steam inlet. pipe and the feeding pipe inclined downward to the right, the inner side of the vertical filter plate and the inner side of the lifting pipe are provided with a mesh belt guide plate, the peeling mechanism includes a peeling drum, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com