Composition for glass, chemical tempered glass as well as preparation method and application thereof

A technology for strengthening glass and composition, applied in the field of glass manufacturing, can solve the problems of difficulty in removing inclusions, low quality of high-viscosity glass melt, etc., and achieve the effects of increasing volume, reducing content and reducing partial pressure of N2 gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

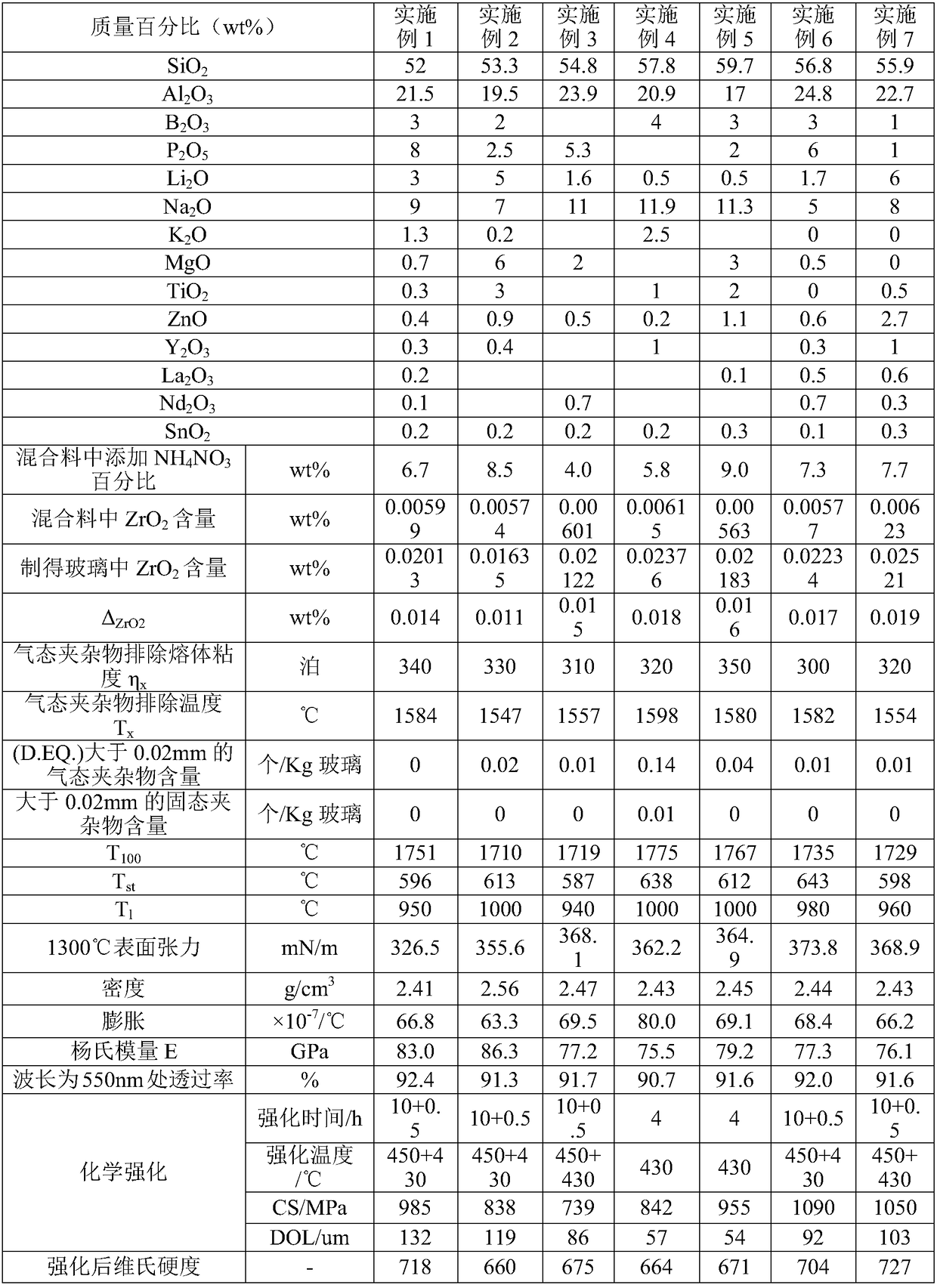

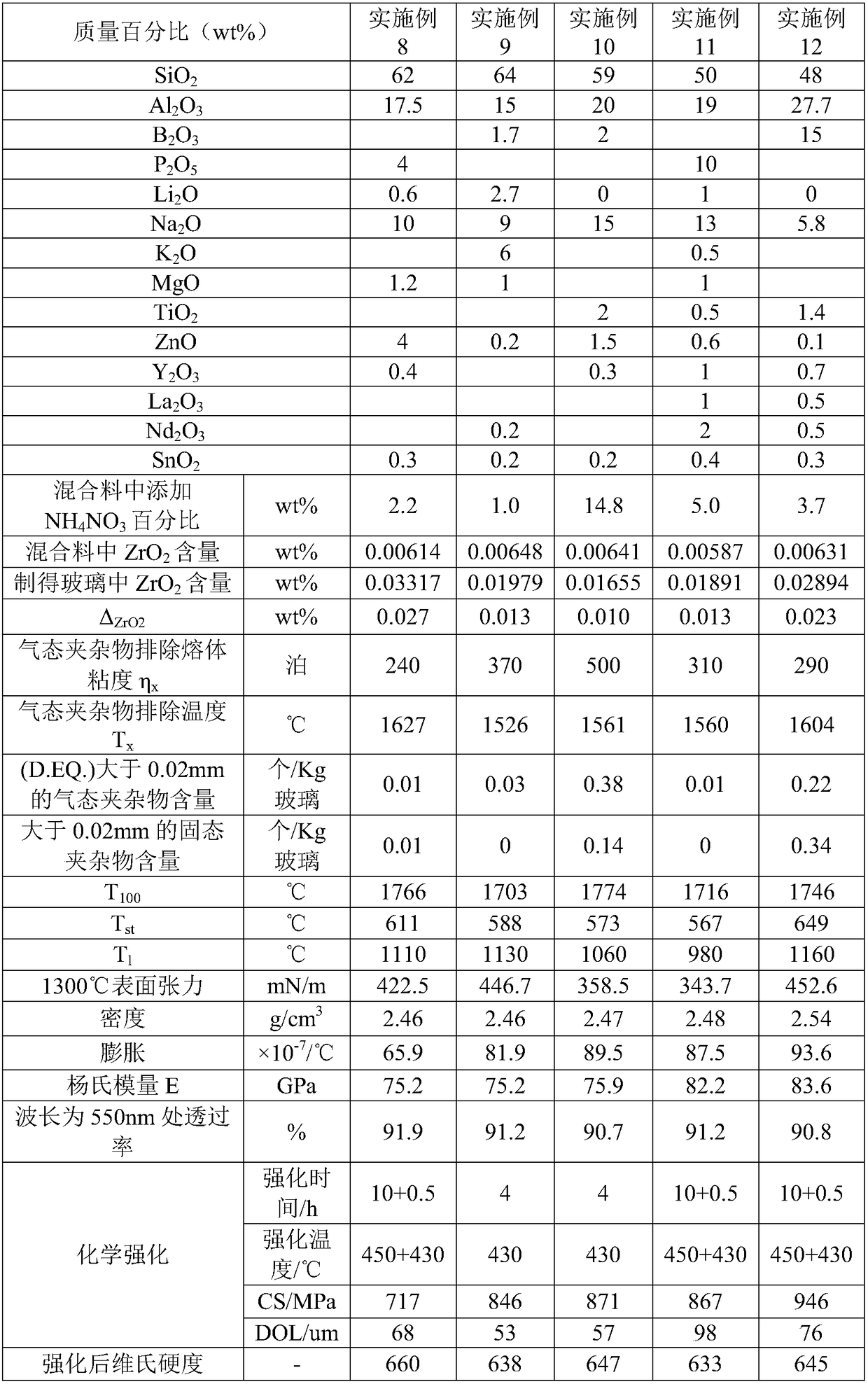

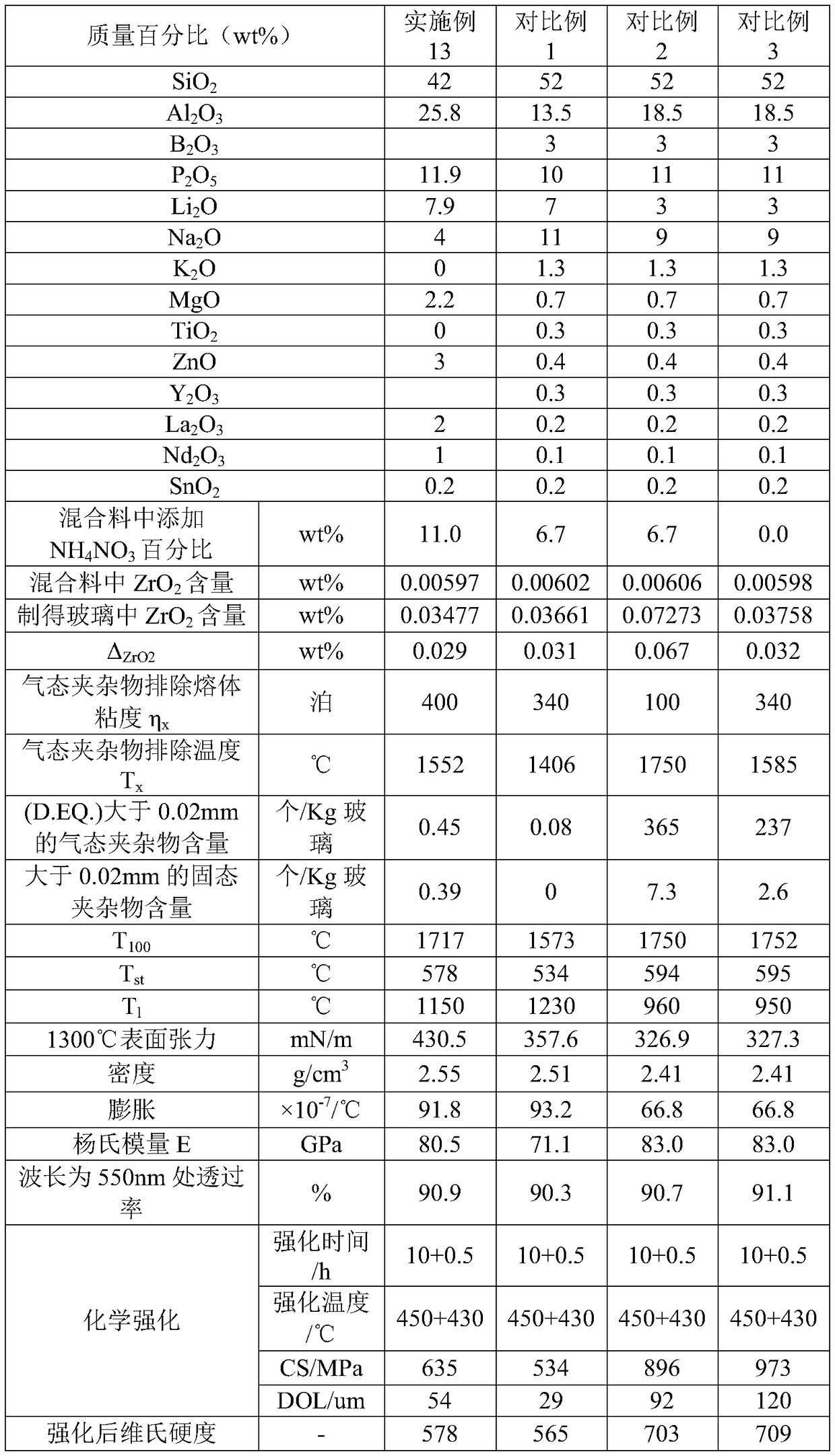

[0051] According to a preferred embodiment of the present invention, the composition contains 52-60wt% SiO 2 , 17-25wt% A1 2 o 3 , 2-11wt% of B 2 o 3 +P 2 o 5 , 5-12wt% Na 2 O, 0.5-6 wt% Li 2 O, 0-2.5 wt% K 2 O, 0.5-9wt% MgO+TiO 2 , 0.2-3wt% ZnO, 0.1-2wt% Y 2 o 3 +La 2 o 3 +Nd 2 o 3 .

[0052] Preferably, the composition contains B 2 o 3 0-15wt%, P 2 o 5 It is 0-11.9wt%, preferably 0-11wt%. e.g. B 2 o 3 0-4wt% and / or P 2 o 5 It is 0-8wt%.

[0053] Preferably, the composition contains 0-6 wt% of MgO, TiO 2 It is 0-3wt%. eg MgO 0-3wt% and / or TiO 2 0-2wt%

[0054] Preferably, the composition contains Y 2 o 3 0-1wt%, La 2 o 3 0-2wt%, Nd 2 o 3 0-2wt%. e.g. Y 2 o 3 0.1-1wt%, La 2 o 3 0.1-0.6wt% and / or Nd 2 o 3 It is 0.1-0.7wt%.

[0055] According to the present invention, the composition for glass of the present invention may further contain a chemical clarifier as necessary. The chemical clarifier is not particularly limited, and may be an...

Embodiment 1-13、 comparative example 1-3

[0104] Weigh each raw material component according to the ratio shown in Table 1-3, mix well, and pour the mixture into a high zirconium brick crucible (ZrO 2 >85wt%), then in η x Corresponding T of Poise viscosity x Heating in a resistance furnace for 48 hours, and using high zirconium rods (ZrO 2 >85wt%) the stirrer stirs slowly at a constant speed. Pour the molten glass into a stainless steel cast iron mold to form a specified block glass product, then anneal the glass product in an annealing furnace for 2 hours, turn off the power and cool down to 25°C with the furnace. The glass product is cut, ground and polished, then cleaned with deionized water and dried to obtain a glass product with a thickness of 0.5 mm. Part of the glass products are cut, ground and polished, and the surface of the polished glass products of 80×80×0.5 mm is cleaned with deionized water, and chemically strengthened after being preheated in a preheating furnace. Among them, putting Examples 1-3,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com