Fabric defect detection method based on frequency spectrum curvature analysis

A defect detection and frequency component technology, which is applied in the field of fabric defect detection based on spectral curvature analysis, can solve the problems of tedious and cumbersome system adjustment and calibration, the system state is prone to drift, and the system detection accuracy is reduced, so as to achieve stable detection results and detection accuracy. Fast and adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

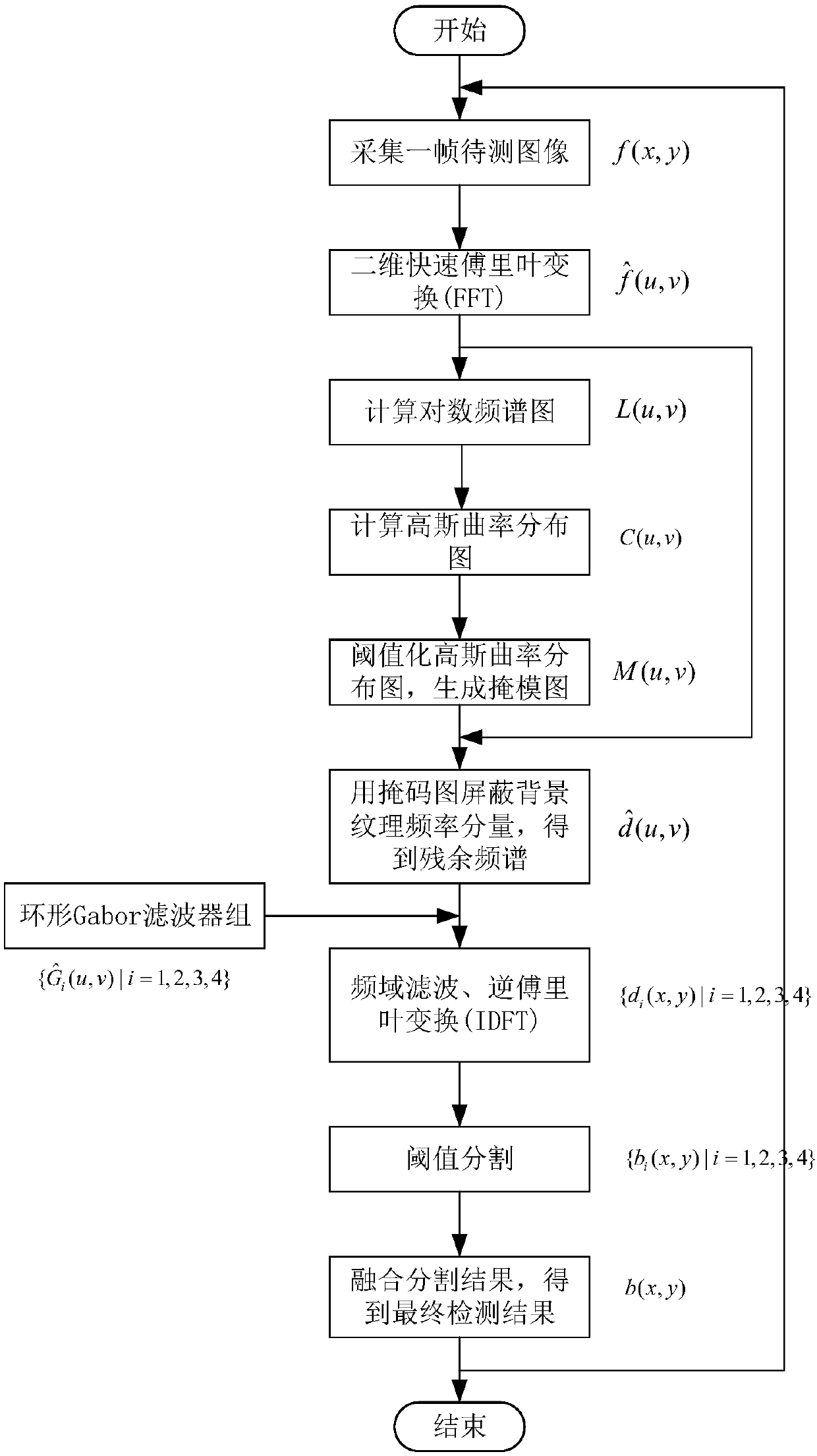

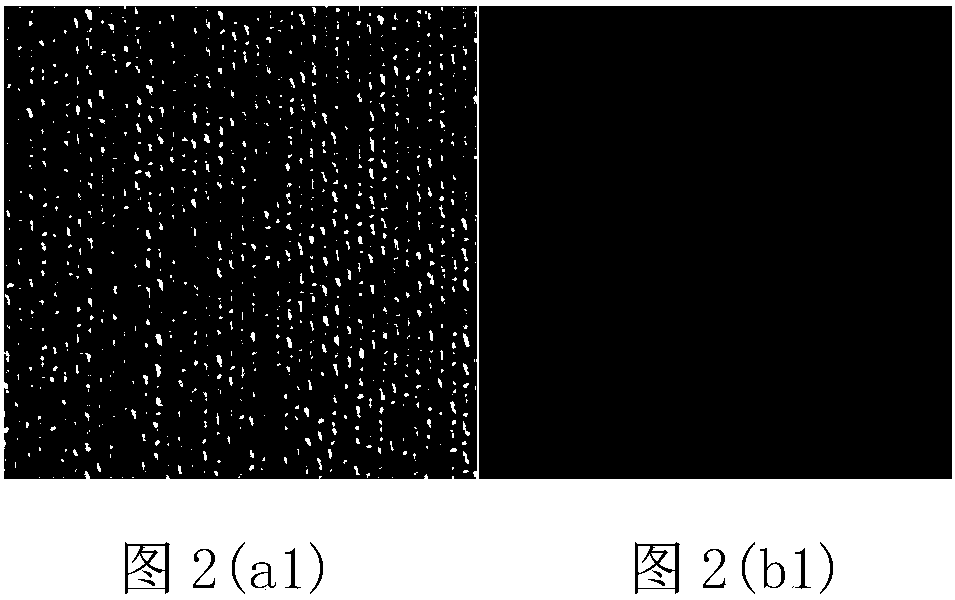

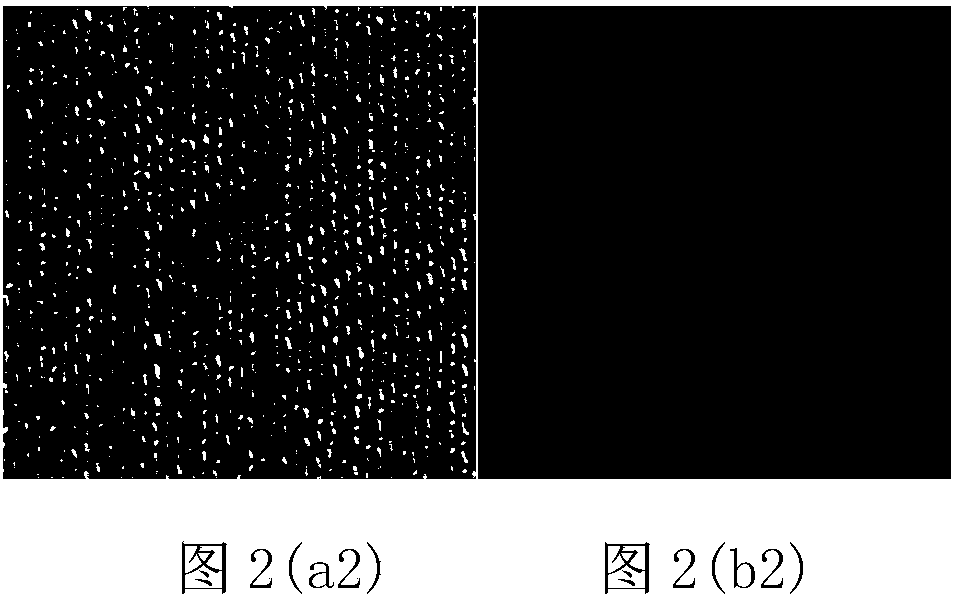

[0058] Such as figure 1 Shown is the processing flowchart of the present invention, step 1, eliminates the periodical texture signal of fabric surface: as shown in Fig. 2 (a1), Fig. 2 (a2) respectively are non-defective and defective fabric image sample, to The input image sample f(x,y) to be tested is subjected to two-dimensional fast Fourier transform (2D FFT) to obtain the transformation result Among them, x, y are horizontal and vertical pixel coordinates, respectively, and u, v are mutually orthogonal spatial frequency coordinates. The value range of is complex, and the corresponding spectrogram is calculated as:

[0059]

[0060] The logarithmic spectrogram L(u,v) is generated from the spectrogram A(u,v), as shown in Figure 2(b1) and Figure 2(b2), which are the logarithmic spectrograms of non-defective and defective samples respectively:

[0061] L(u,v)=log[A(u,v)+1]

[0062] Traverse each pixel in the logarithmic spectrogram, and calculate the Gaussian curvature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com