Method for rapidly predicting cycle performance of lithium battery ternary material

A ternary material, cycle performance technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problem of high cost, achieve good commercial value, reduce the difficulty of testing, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

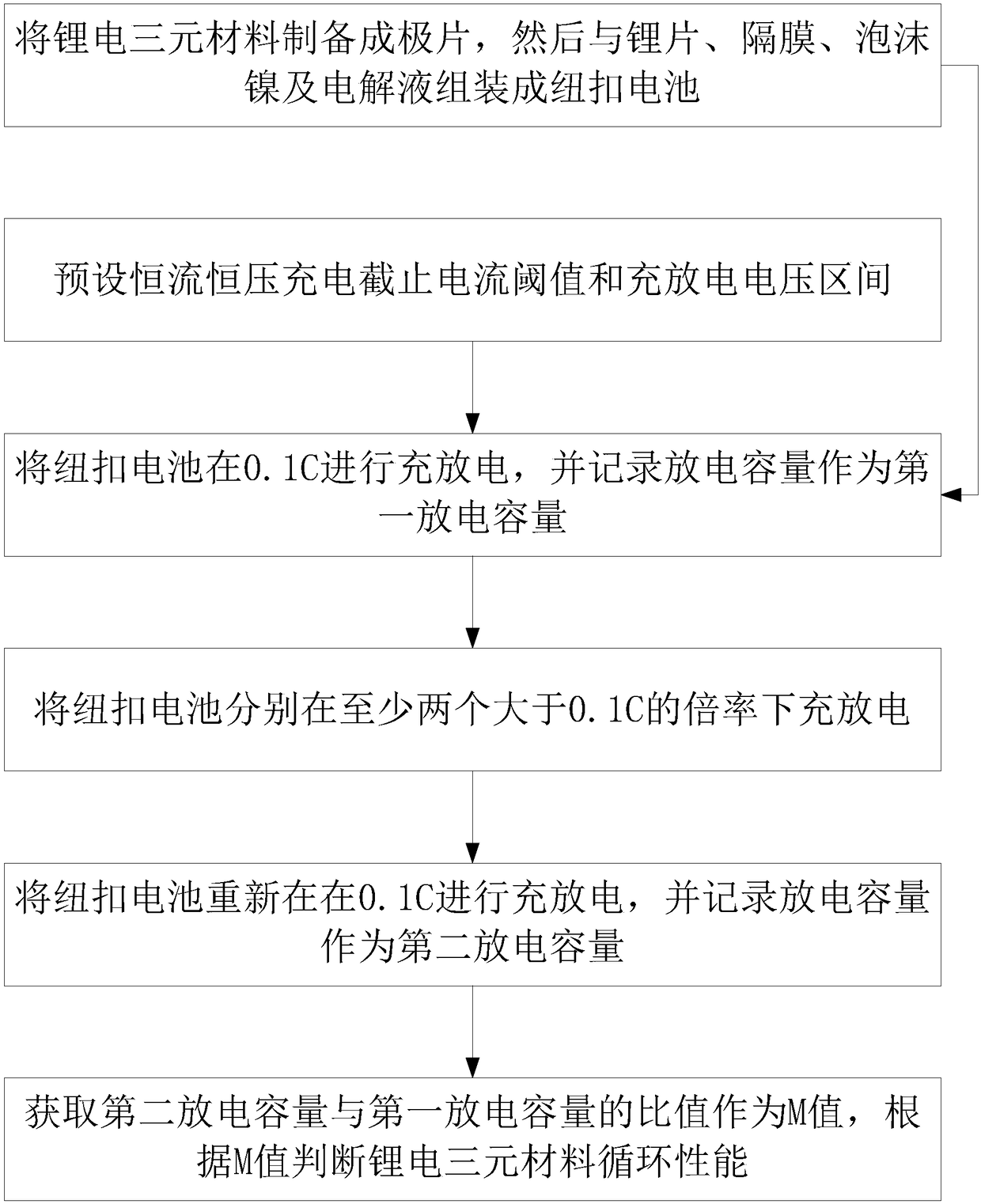

[0031] Example 1: Rapid prediction of LiNi 0.85 co 0.1 mn 0.05 o 2 cycle performance

[0032] First, the lithium battery ternary material LiNi 0.85 co 0.1 mn 0.05 o 2 Prepared into a pole piece, the surface density of the pole piece is 100g / cm 3 , the mass ratio of the ternary material in the pole piece is 80%, and the pole piece, lithium sheet, diaphragm, nickel foam and electrolyte are assembled into a button battery.

[0033] Put the button battery into the test cabinet for testing, first charge and discharge at 0.1C, the charge and discharge voltage range is 2.75-4.3V, the cut-off current of constant current and constant voltage charging is 0.05C, and then charge at 0.2C, 1C, and 2C respectively Discharge, and finally drop back to 0.1C for charge and discharge, divide the discharge capacity of the second 0.1C by the discharge capacity of the first 0.1C, calculate the ratio M, and then judge the cycle performance of the ternary material according to the M value.

Embodiment 2

[0034] Example 2: Rapid prediction of LiNi 0.85 co 0.1 mn 0.05 o 2 cycle performance

[0035] First, the lithium battery ternary material LiNi 0.85 co 0.1 mn 0.05 o 2 Prepared into a pole piece, the surface density of the pole piece is 100g / cm 3 , the mass ratio of the ternary material in the pole piece is 80%, and the pole piece, lithium sheet, diaphragm, nickel foam and electrolyte are assembled into a button battery.

[0036] Put the button battery into the test cabinet for testing, first charge and discharge at 0.1C, the charge and discharge voltage range is 2.75-4.3V, the cut-off current of constant current and constant voltage charging is 0.05C, and then charge and discharge at 0.2C, 1C, 2C, 3C respectively , 4C, 5C for charge and discharge, and finally drop back to 0.1C for charge and discharge, divide the discharge capacity of the second 0.1C by the discharge capacity of the first 0.1C, calculate the ratio M, and then judge the ternary material according to the...

Embodiment 3

[0037] Example 3: Rapid prediction of LiNi 0.333 co 0.333 mn 0.333 o 2 cycle performance

[0038] First, the lithium battery ternary material LiNi 0.333 co 0.333 mn 0.333 o 2 Prepared into pole pieces, the surface density of the pole piece is

[0039] 200g / cm 3 , the mass ratio of the ternary material in the pole piece is 95%, and the pole piece, lithium sheet, diaphragm, nickel foam and electrolyte are assembled into a button battery.

[0040] Put the button battery into the test cabinet for testing, first charge and discharge at 0.1C, the charge and discharge voltage range is 2.75-4.3V, the cut-off current of constant current and constant voltage charging is 0.05C, and then charge at 0.2C, 1C, and 2C respectively Discharge, and finally drop back to 0.1C for charge and discharge, divide the discharge capacity of the second 0.1C by the discharge capacity of the first 0.1C, calculate the ratio M, and then judge the cycle performance of the ternary material according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com