Optical imaging element and manufacturing method thereof

An optical imaging and manufacturing method technology, applied in optical components, optics, instruments, etc., can solve the problems of high production cost of optical imaging components, inability to mass-produce at low prices, complex production processes, etc., and achieve low-cost mass production and production. The effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

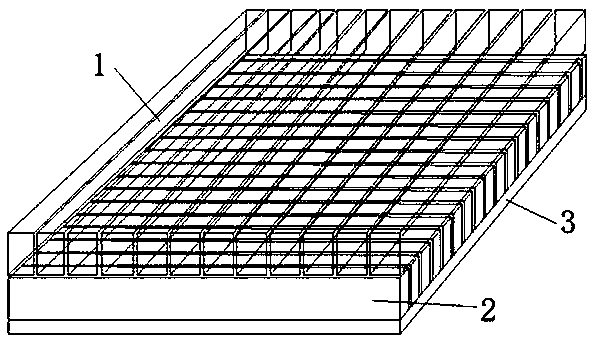

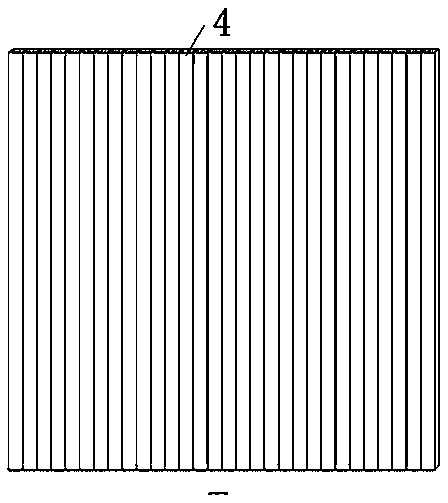

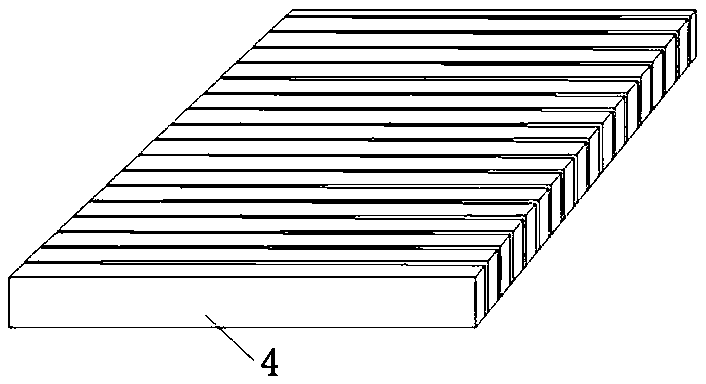

[0026] like Figure 1 to Figure 11 As shown, an optical imaging element, the optical imaging element is mainly composed of an upper transparent laminated body 1 and a lower transparent laminated body 2, the upper transparent laminated body 1 and the lower transparent laminated body 2 are composed of several strips The slender transparent strip 4 of the single-sided or double-sided metal reflective layer 5 is glued together, and the slender transparent strip 4 between the upper light-transmitting laminate 1 and the lower light-transmitting laminate 2 is vertically arranged, and the two light-transmitting laminates The direction of the internal reflection surface of the inner reflection surface forms an orthogonal arrangement, and the upper layer of transparent laminated body 1 and the lower layer of transparent laminated body 2 are bonded toge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com