Vacuum film pasting apparatus and method

A film sticking device and vacuum technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of bonding strength influence, poor bonding, etc., to improve air density, improve yield, improve quality and yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

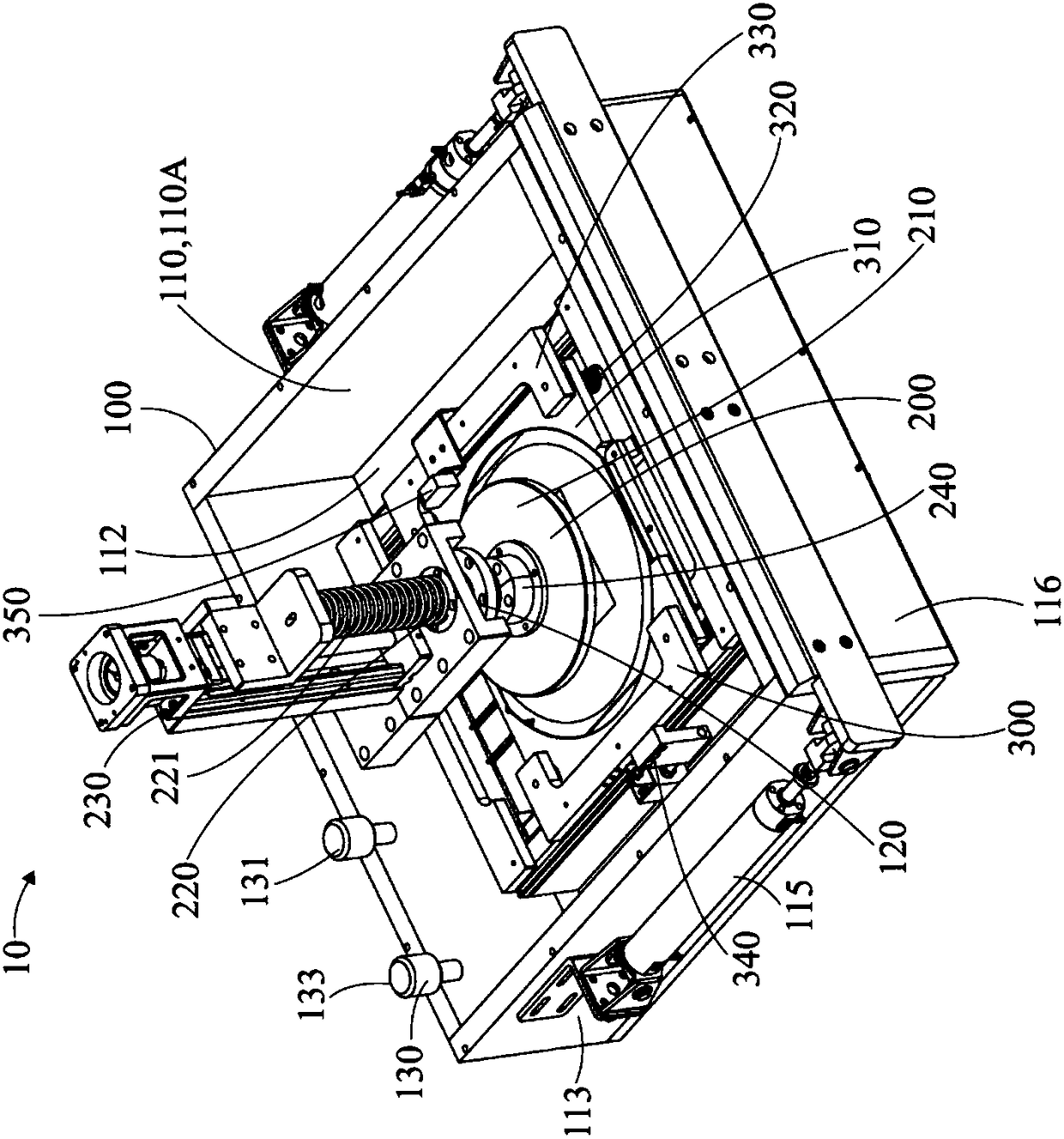

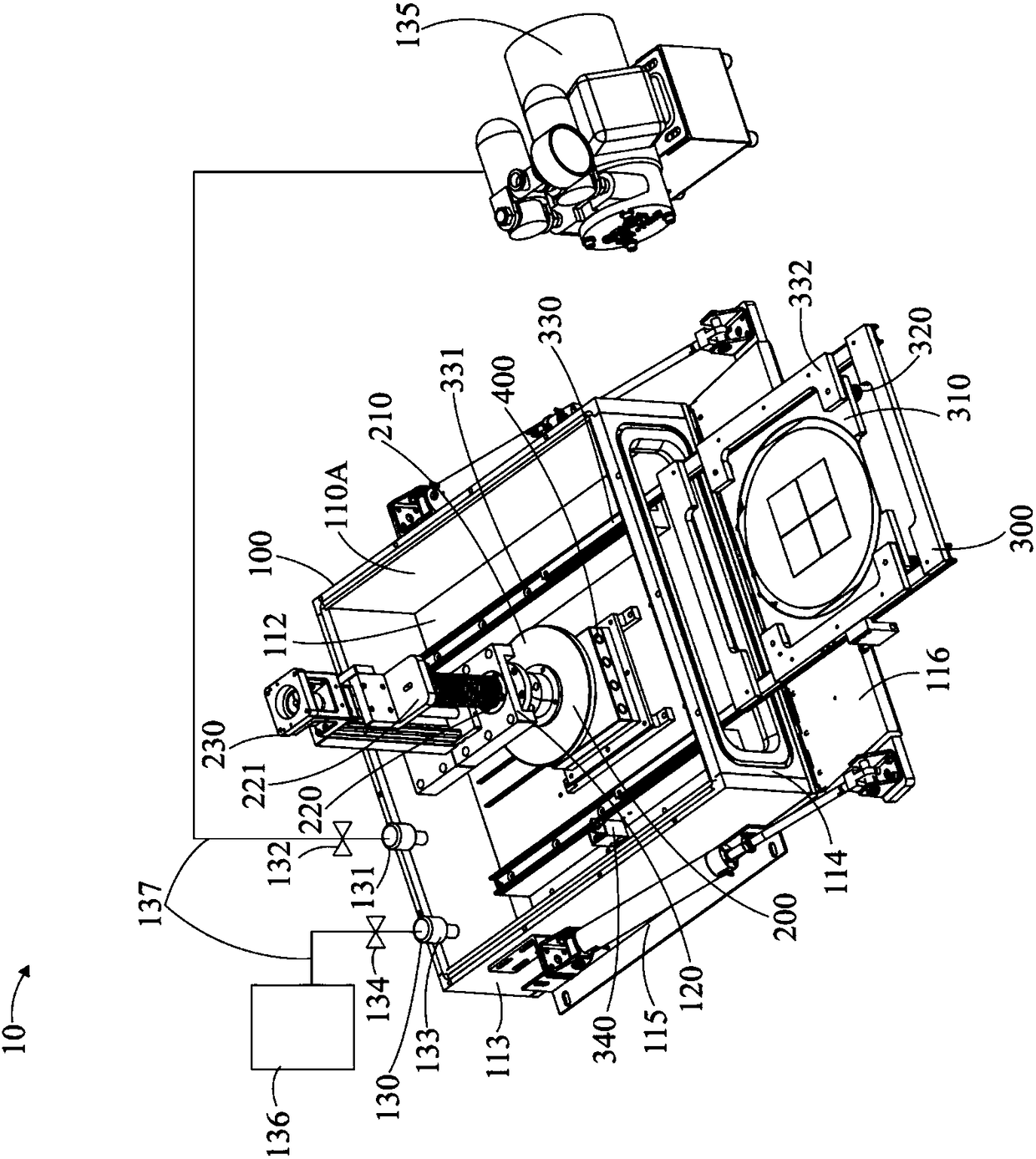

[0099] see Figure 1 to Figure 3 As shown, it is a schematic diagram of a vacuum film sticking device 10 according to a preferred embodiment of the present invention, wherein figure 1 and figure 2 The top plate 111 of the cavity 110 is not shown in order to view the internal structure of the vacuum film sticking device 10 . The vacuum laminating device 10 may include a vacuum chamber module 100 , a lamination module 200 , a carrying module 300 and a heating platform 400 , and the technical contents of these components are described in sequence as follows.

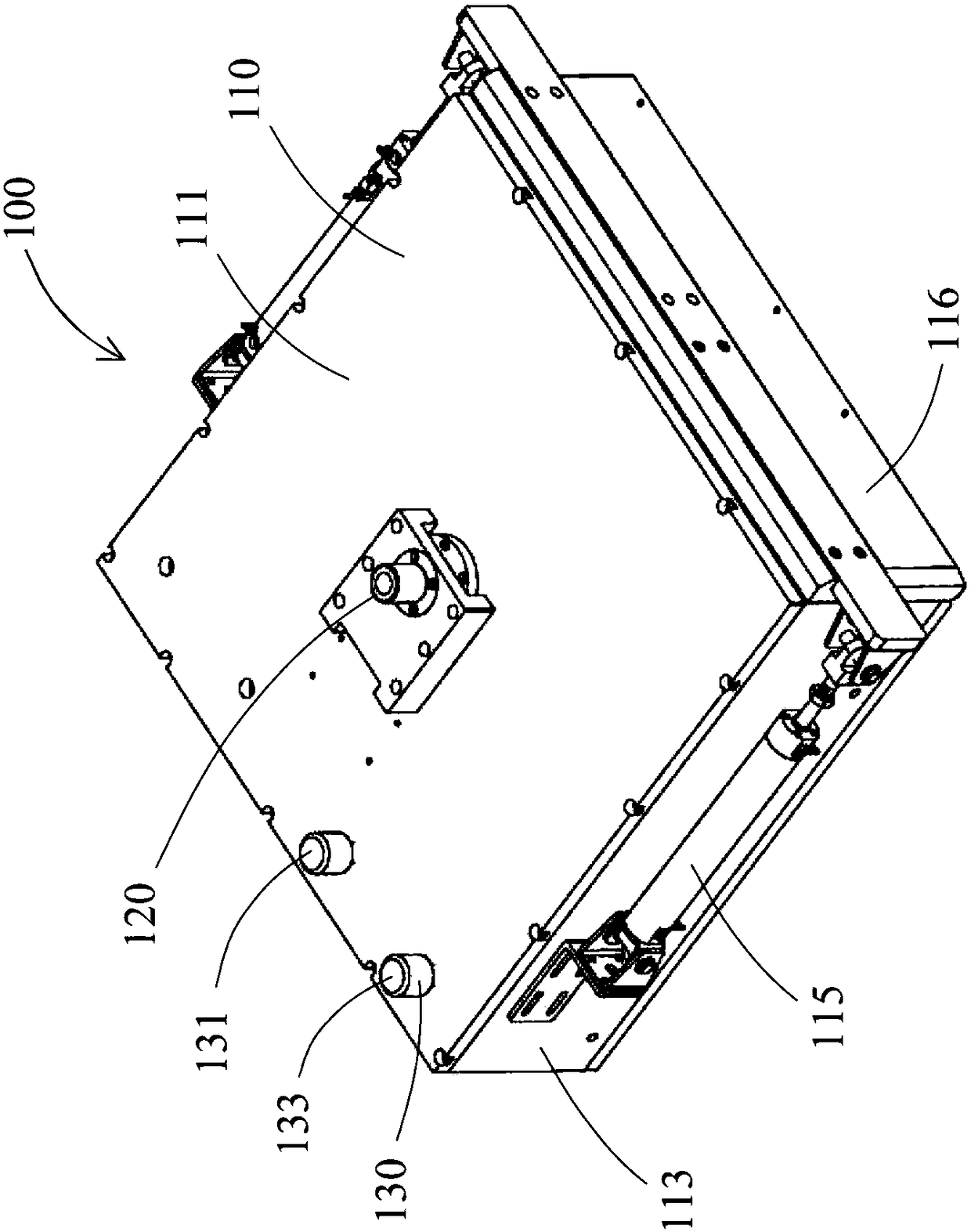

[0100] The vacuum chamber module 100 can provide a vacuum environment for vacuum film lamination, and its structure can include a cavity 110, an airtight sliding bearing 120 and a vacuum system control device 130, the airtight sliding bearing 120 and the control device 130 are all disposed on the cavity 110 .

[0101] Specifically, the cavity 110 defines an accommodating space 110A, and the pressure therein is controlla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com