High-strength touch screen glass substrate and preparation method thereof

A glass substrate, touch screen technology, applied in glass production and other directions, can solve problems such as affecting the mechanical strength and light transmittance of glass, increasing the difficulty of glass clarification, and increasing the viscosity of glass melt, so as to improve mechanical strength and light transmittance. , The effect of reducing bubble defects and low bubble defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

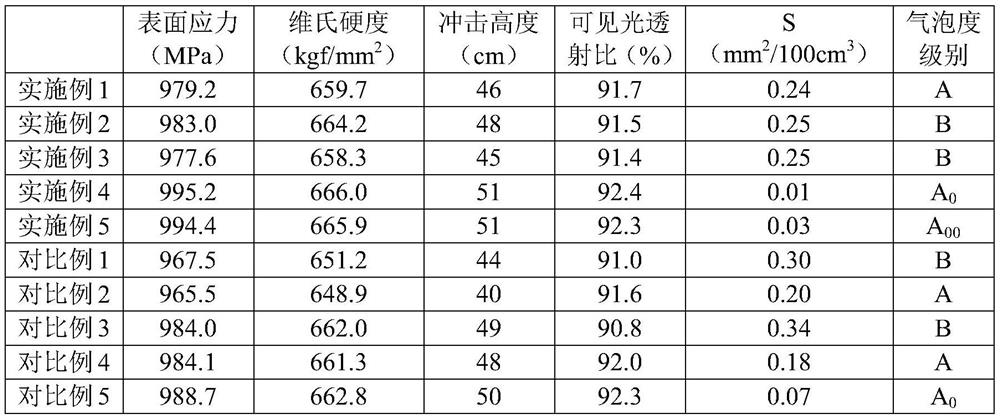

Examples

Embodiment 1

[0057] A high-strength touch screen glass substrate, based on oxides, includes the following components in parts by weight: SiO 2 70 copies, Al 2 o 3 14.3 parts, Na 2 O 13 parts, K 2 O 3 parts, CaO 3.5 parts, MgO 3.8 parts, SnO 0.3 parts, ZrO 2 0.05 parts, P 2 o 5 0.3 parts, B 2 o 3 0.8 servings.

[0058] A method for preparing a touch screen glass substrate, comprising the following steps:

[0059] (1) glass raw materials and clarifiers are provided; the glass raw materials include the following components: quartz sand, aluminum oxide, sodium carbonate, potassium carbonate, calcium carbonate, magnesium oxide, zirconium dioxide, phosphorus pentoxide and boron oxide; The clarifying agent comprises the following components: sodium sulfate, carbon powder and tin dioxide; calculate the consumption ratio of each raw material in parts by weight of the oxide, and take each raw material by the dosage ratio; the mass ratio of the sodium carbonate to sodium sulfate 9:1, th...

Embodiment 2

[0064] A high-strength touch screen glass substrate, based on oxides, includes the following components in parts by weight: SiO 2 74 parts, Al 2 o 3 14 parts, Na 2 O 14.5 parts, K 2 2.8 parts of O, 3 parts of CaO, 4.2 parts of MgO, 0.15 parts of SnO, ZrO 2 0.08 parts, P 2 o 5 0.15 parts, B 2 o 3 0.9 servings.

[0065] A method for preparing a touch screen glass substrate, comprising the following steps:

[0066] (1) glass raw materials and clarifiers are provided; the glass raw materials include the following components: quartz sand, aluminum oxide, sodium carbonate, potassium carbonate, calcium carbonate, magnesium oxide, zirconium dioxide, phosphorus pentoxide and boron oxide; The clarifying agent comprises the following components: sodium sulfate, carbon powder and tin dioxide; calculate the consumption ratio of each raw material in parts by weight of the oxide, and take each raw material by the dosage ratio; the mass ratio of the sodium carbonate to sodium sul...

Embodiment 3

[0071] A high-strength touch screen glass substrate, based on oxides, includes the following components in parts by weight: SiO 2 80 copies, Al 2 o 3 16.5 parts, Na 2 O 16 parts, K 2 O 2 parts, CaO 2.7 parts, MgO 4.6 parts, SnO 0.1 parts, ZrO 2 0.1 part, P 2 o 5 0.1 part, B 2 o 3 1.3 servings.

[0072] A method for preparing a touch screen glass substrate, comprising the following steps:

[0073](1) glass raw materials and clarifiers are provided; the glass raw materials include the following components: quartz sand, aluminum oxide, sodium carbonate, potassium carbonate, calcium carbonate, magnesium oxide, zirconium dioxide, phosphorus pentoxide and boron oxide; The clarifying agent comprises the following components: sodium sulfate, carbon powder and tin dioxide; calculate the consumption ratio of each raw material in parts by weight of the oxide, and take each raw material by the dosage ratio; the mass ratio of the sodium carbonate to sodium sulfate is 11:1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com