Flexible tio with visible light catalytic performance 2 /pvdf@mos 2 Composite nanofiber and preparation method thereof

A technology of composite nanofibers and catalytic performance, applied in the direction of catalyst activation/preparation, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of fast recombination rate of photogenerated electrons and holes, difficulties in separation and recovery, low photocatalytic activity, etc. problem, to achieve good catalytic performance, mild experimental conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

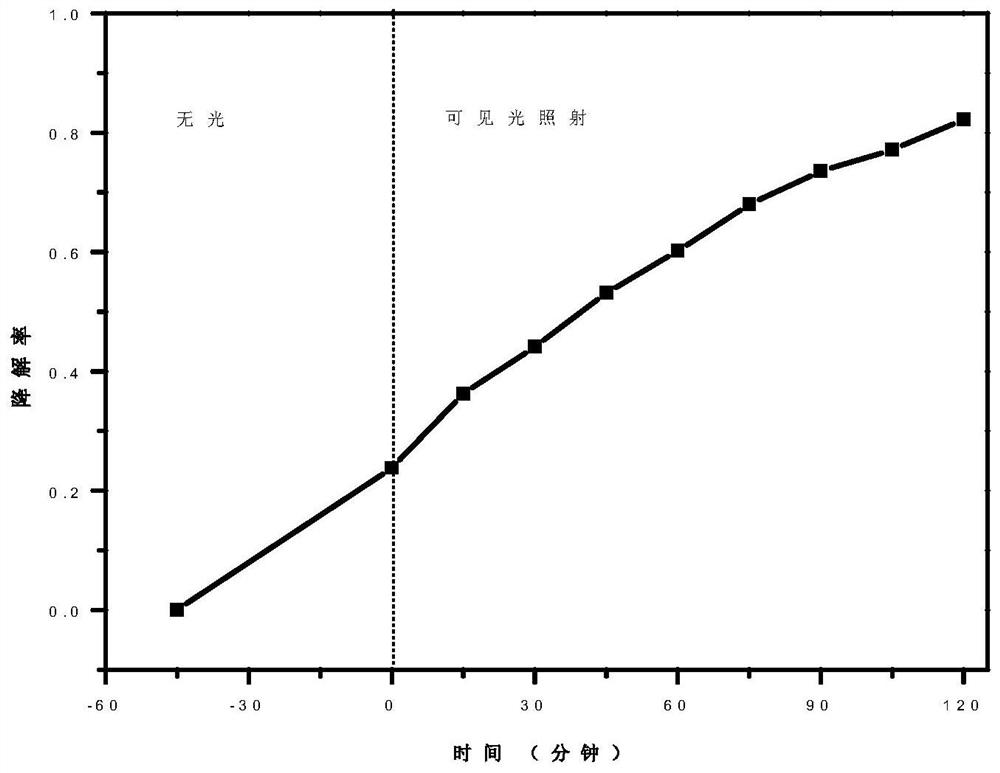

Embodiment 1

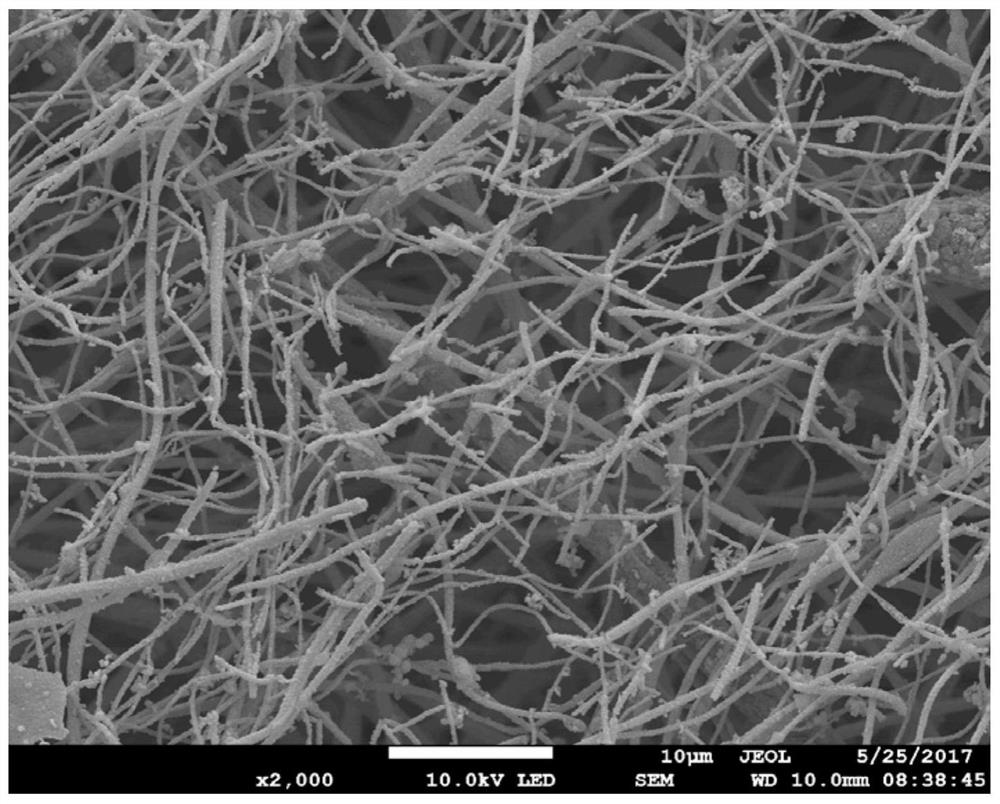

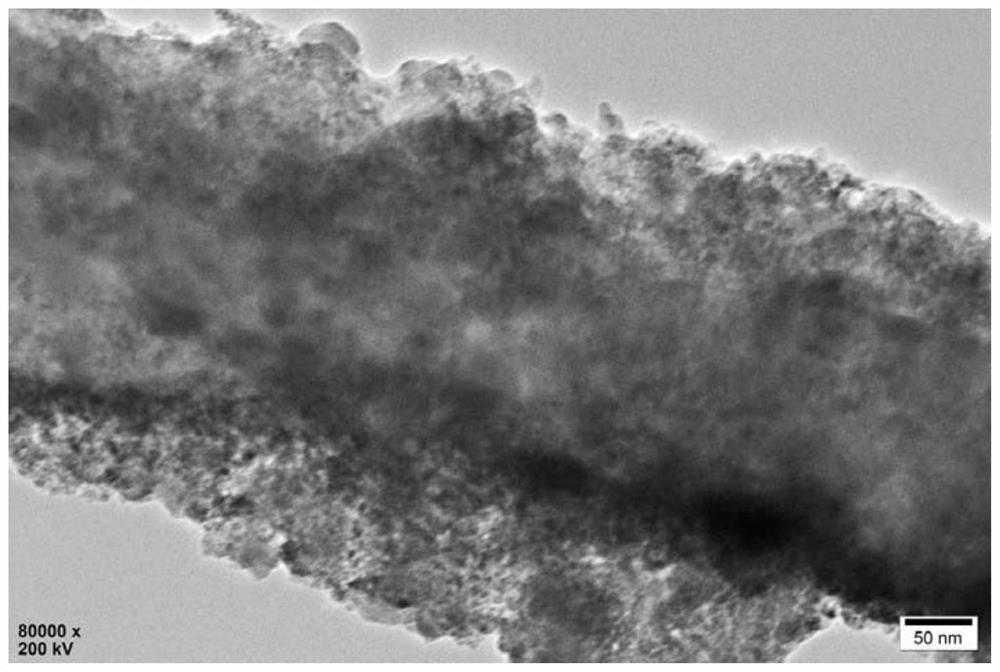

[0029] A flexible TiO with visible light catalytic performance 2 / PVDF@MoS 2 The preparation method of composite nanofiber comprises the following steps:

[0030](1) The mass percentage content of configuration PVDF is 16.7%, and the solvent is 24g of the solution of DMF and acetone mixed solution, wherein, PVDF 4g, DMF and acetone mixed solution 20g, DMF and acetone mass percentage are 1:1, use magnetic stirrer Stir the solution at 40°C for 2h, then add 10mL TBOT solution to the container, and keep stirring for 1h to obtain the TBOT / PVDF spinning precursor solution;

[0031] (2) The prepared solution was used for electrospinning, wherein the spinning voltage was 9kV, and the spinning distance was 11cm. The solution is spun into fibers, collected on a pole drum, and finally deposited to obtain a fiber film;

[0032] (3) Dry the fiber film obtained in step (2) in an oven at 60°C for 10 hours, and then cut it into small square pieces of 2 cm×2 cm;

[0033] (4) Under normal t...

Embodiment 2

[0040] A flexible TiO with visible light catalytic performance 2 / PVDF@MoS 2 The preparation method of composite nanofiber comprises the following steps:

[0041] (1) The mass percentage content of configuration PVDF is 16.7%, and the solvent is 24g of the solution of DMF and acetone mixed solution, wherein, PVDF 4g, DMF and acetone mixed solution 20g, DMF and acetone mass percentage are 1:1, use magnetic stirrer Stir the solution at 40°C for 2h, then add 10mL TBOT solution to the container, and keep stirring for 1h to obtain the TBOT / PVDF spinning precursor solution;

[0042] (2) Use the prepared solution for electrospinning. The spinning voltage is 9kV, and the spinning distance is 11cm. The solution is spun into fibers, collected on a pole drum, and finally deposited as a fiber film;

[0043] (3) Dry the obtained TBOT / PVDF fiber membrane in an oven at 60°C for 10 hours, and then cut it into square pieces of 2cm×2cm;

[0044] (4) Under normal temperature conditions, wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com