Double-saw-blade cutting machine

A cutting machine and double saw blade technology, applied in metal sawing equipment, sawing machine devices, sawing machine tools and other directions, can solve the problems of high labor intensity, the accuracy and quality of sheet materials cannot be guaranteed, and the cutting efficiency is low. The effect of reduced labor intensity, low cost and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

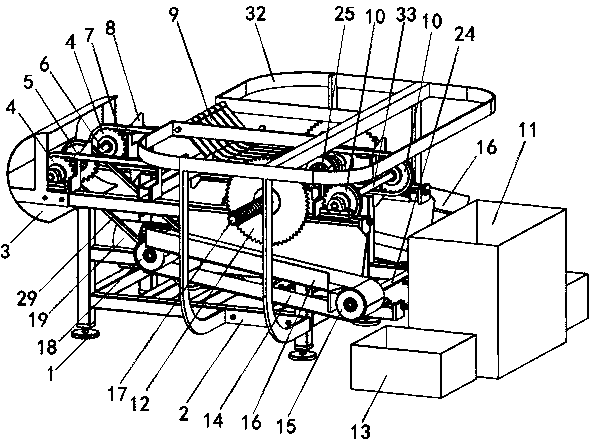

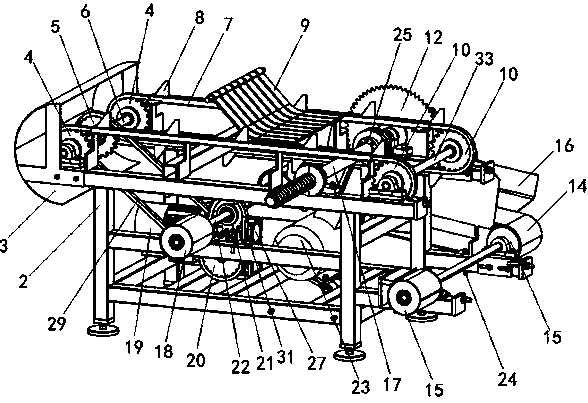

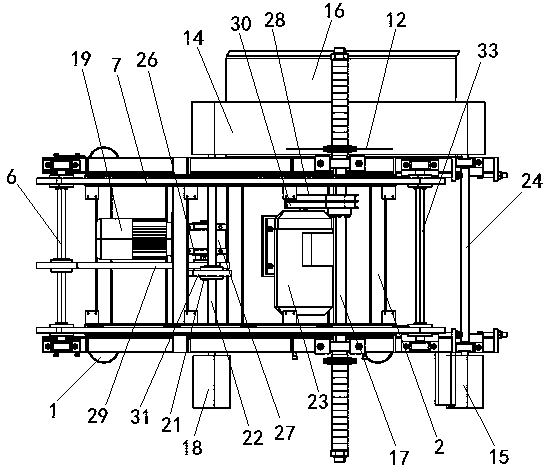

[0030] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0031] see Figure 1-3 As shown, a double-saw blade cutting machine is composed of a frame 2, and a feeding and discharging mechanism, a pressing mechanism, a cutting mechanism and a residual material blanking mechanism installed on the frame 2. The frame 2 The bottom is provided with an adjustable foot support 1;

[0032] The feeding and discharging mechanism includes a feeding drive motor 19, a reducer 27, a feeding driving shaft 6, a feeding driven shaft 33, a feeding chain driving wheel 4, a feeding chain driven wheel 10, a feeding chain 7, a feeding transmission belt 29, and a feeding driving shaft Driven wheel 5 and feeding driving shaft driving wheel 26; described feeding driving motor 19 and described speed reducer 27 are all installed in the lower floor of described frame 2, and described feeding driving motor 19 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com