Quenching car

A coke quenching vehicle and vehicle body technology, which is applied in coke ovens, coke cooling, petroleum industry, etc., can solve the problems that the spray quenching time cannot be extended infinitely, the belt of the coke drying table is easy to burn out, and the thickness of coke is increased. Achieve the effect of improving the turnover rate of coke oven, good coke quenching effect and shortening coke quenching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

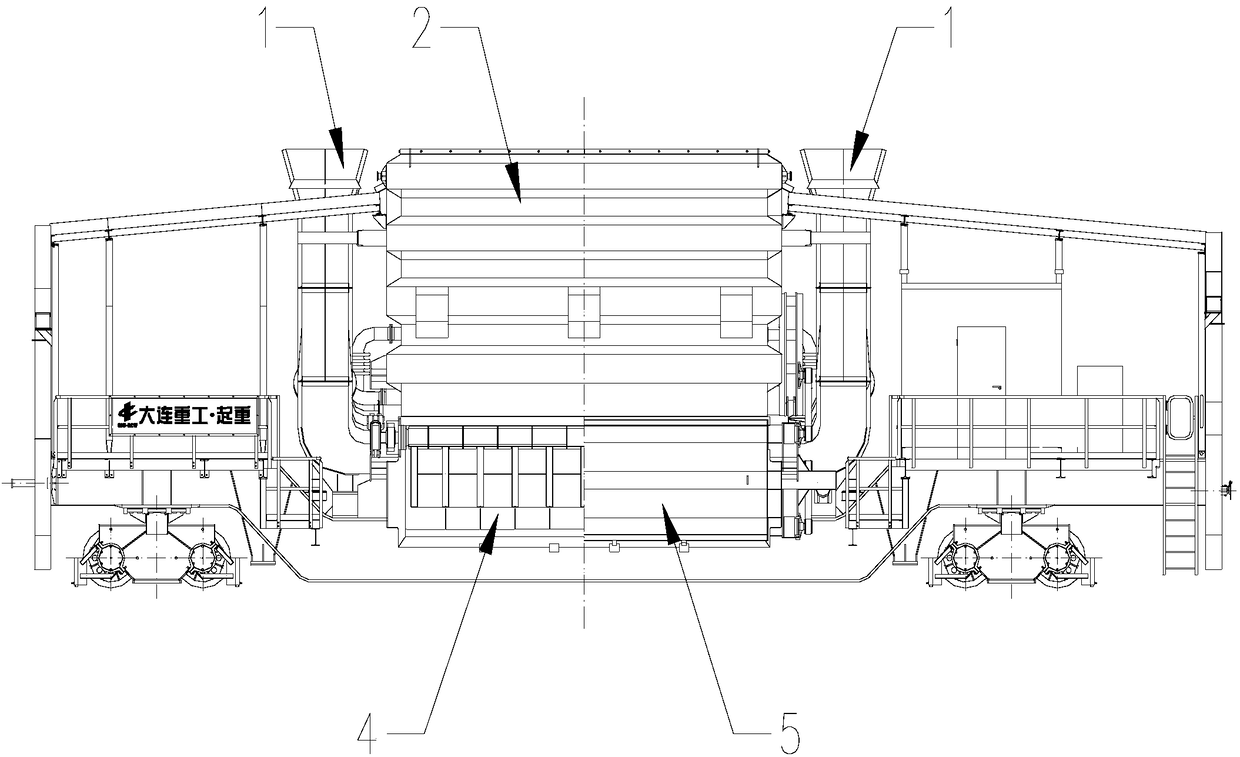

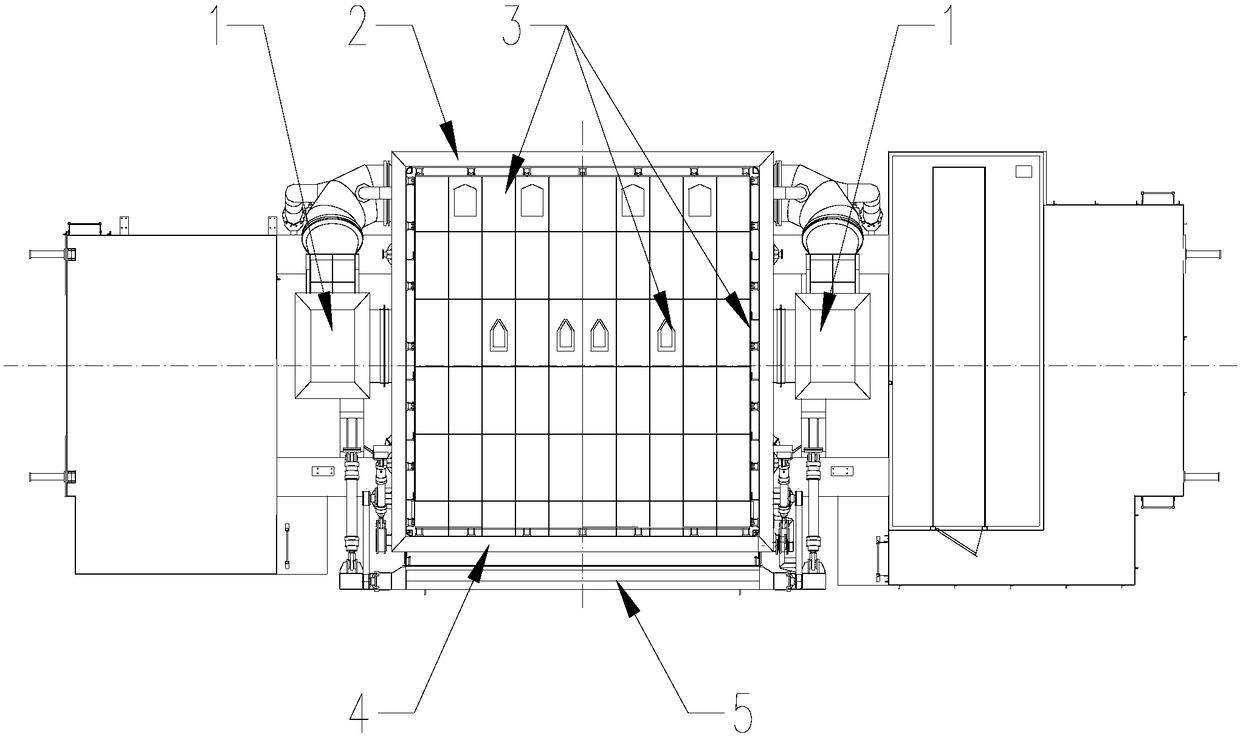

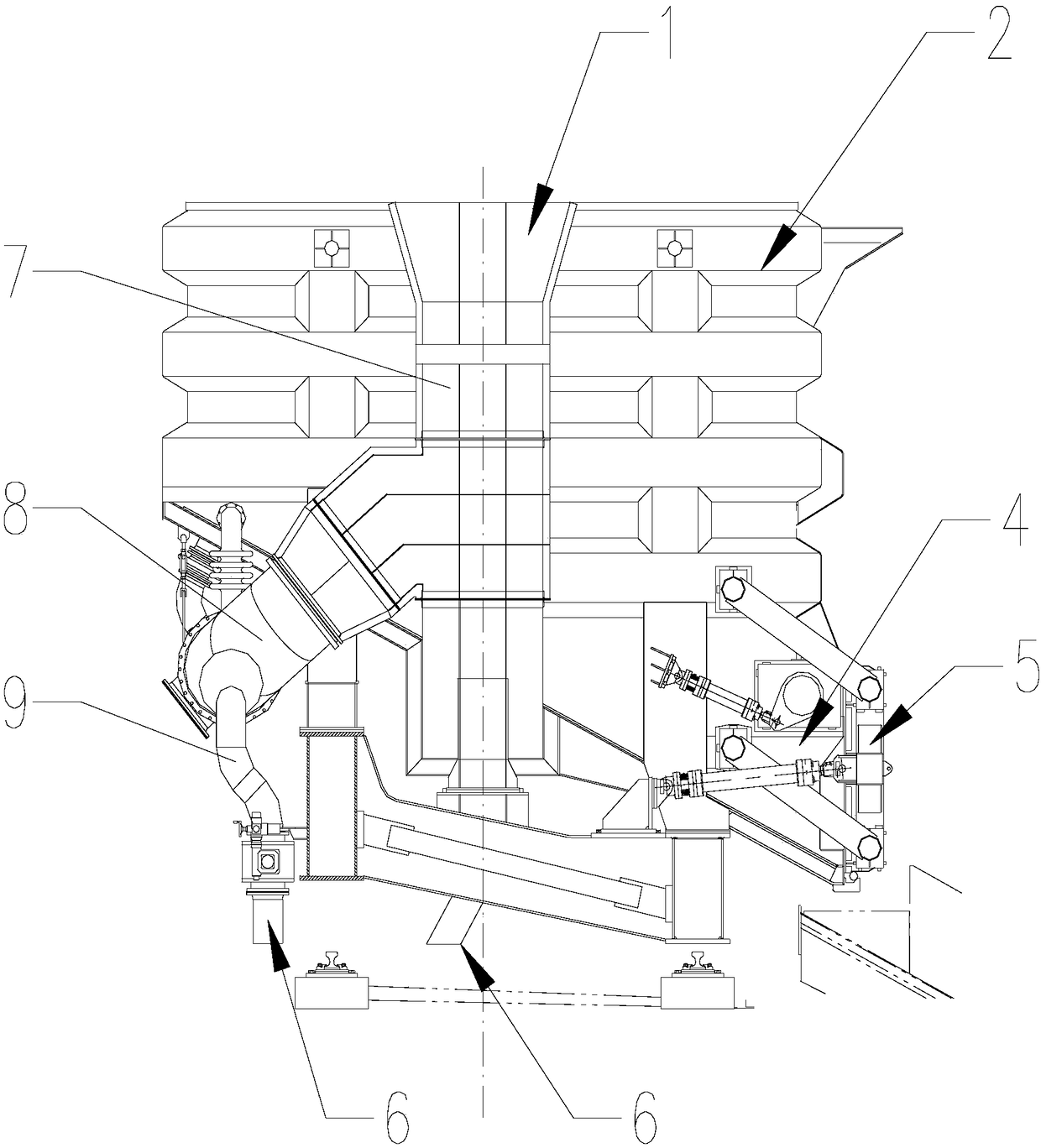

[0039] Specific embodiments of the present invention are shown in the accompanying drawings, the coke quenching vehicle includes: a vehicle body and a water injection system; the water injection system is arranged outside the vehicle body and communicates with the interior of the vehicle body through the vehicle body;

[0040] The car body includes: the coke bucket device 2, the inner flap 4 and the outer flap 5; the coke bucket device 2, the inner flap 4 and the outer flap 5 form a compartment with an open top and the other five sides are closed;

[0041] The water injection system includes: a water injection port 1, a water outlet 3, a water outlet 6 and a water pipeline; the water injection port 1 is arranged outside the coke bucket device 2 and communicates with the water pipeline; the water pipeline is connected to the water outlet 3 arranged on the coke bucket device 2 There are multiple water outlets 6 on the water pipeline.

[0042] The water pipeline includes: main wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com