Preparation method of amino CQD (carbon quantum dot) fluorescence and 4-nitrophenol molecularly imprinted sensor

A technology of p-nitrophenol and amino carbon quantum, which is applied in the direction of fluorescence/phosphorescence, instruments, measuring devices, etc., to achieve the effects of high conversion rate, expanded application range, and high optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

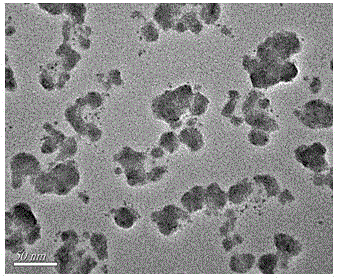

[0025] (1) Add 2g of citric acid and 1g of polyethyleneimine into 30mL of deionized water, and fully dissolve to obtain a transparent solution. Then transfer the mixed solution to a hydrothermal reaction kettle with a volume of 50mL, place the reaction kettle in an oven, heat up to 160°C, react for 4 hours, and cool to room temperature to obtain an amino carbon quantum with high-performance fluorescent properties The dispersion of dots; the dispersion is centrifuged, and the supernatant is preserved to obtain an amino carbon quantum dot solution.

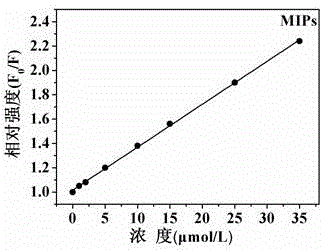

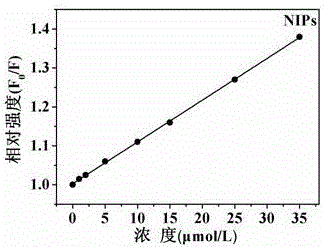

[0026] (2) In a 100mL round bottom flask, add 0.5mL of the aminocarbon quantum dot solution obtained in step (1) and 55mL of ethanol, ultrasonically disperse, and 2Under certain conditions, add 0.05mmol p-nitrophenol, 0.2mmolAM, 0.6mmol EGDMA, 5mgAIBN, then seal the flask, place it in a water bath shaker, pre-polymerize at 48°C for 5h, and polymerize at 58°C for 20h. After the reaction, wash with ethanol Several times to remove unr...

Embodiment 2

[0028] (1) Add 2g of citric acid and 2g of polyethyleneimine into 40mL of deionized water, and fully dissolve to obtain a transparent solution. Then transfer the mixed solution to a hydrothermal reaction kettle with a volume of 50mL, place the reaction kettle in an oven, heat up to 200°C, react for 8 hours, and cool to room temperature to obtain aminocarbon quantum dots with high-performance fluorescent properties The dispersion liquid; the dispersion liquid is centrifuged, and the supernatant is preserved to obtain an amino carbon quantum dot solution.

[0029] (2) In a 100mL round bottom flask, add 0.5mL of the amino carbon quantum dot solution obtained in step (1) and 65mL of ethanol, ultrasonically disperse, and 2 Under certain conditions, add 0.05mmol p-nitrophenol, 0.4mmolAM, 1mmol EGDMA, 10mgAIBN, then seal the flask, place it in a water bath shaker, pre-polymerize at 52°C for 7h, and polymerize at 62°C for 28h. After the reaction, wash with ethanol for several times t...

Embodiment 3

[0031] (1) Add 2g of citric acid and 1.5g of polyethyleneimine into 35mL of deionized water, and fully dissolve to obtain a transparent solution. Then transfer the mixed solution to a hydrothermal reaction kettle with a volume of 50mL, place the reaction kettle in an oven, heat up to 180°C, react for 6 hours, and cool to room temperature to obtain aminocarbon quantum dots with high-performance fluorescent properties of the dispersion. The dispersion liquid is centrifuged, and the supernatant liquid is preserved to obtain an amino carbon quantum dot solution.

[0032] (2) In a 100mL round bottom flask, add 0.5mL of the aminocarbon quantum dot solution obtained in step (1) and 60mL of ethanol, ultrasonically disperse, and 2 Under certain conditions, add 0.05mmol p-nitrophenol, 0.3mmol AM, 0.8mmol EGDMA, 8mgAIBN, then seal the flask, place it in a water bath shaker, pre-polymerize at 50°C for 6h, and polymerize at 60°C for 24h. After the reaction, wash with ethanol Several time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com