Fermenting machine used for broussonetia papyrifera fermented feed

A technology for fermenting feed and fermenter, which is applied to feed, bioreactors/fermenters for specific purposes, and methods of sampling biological materials, etc., can solve the problems that paper mulberry fermenters cannot ferment continuously.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

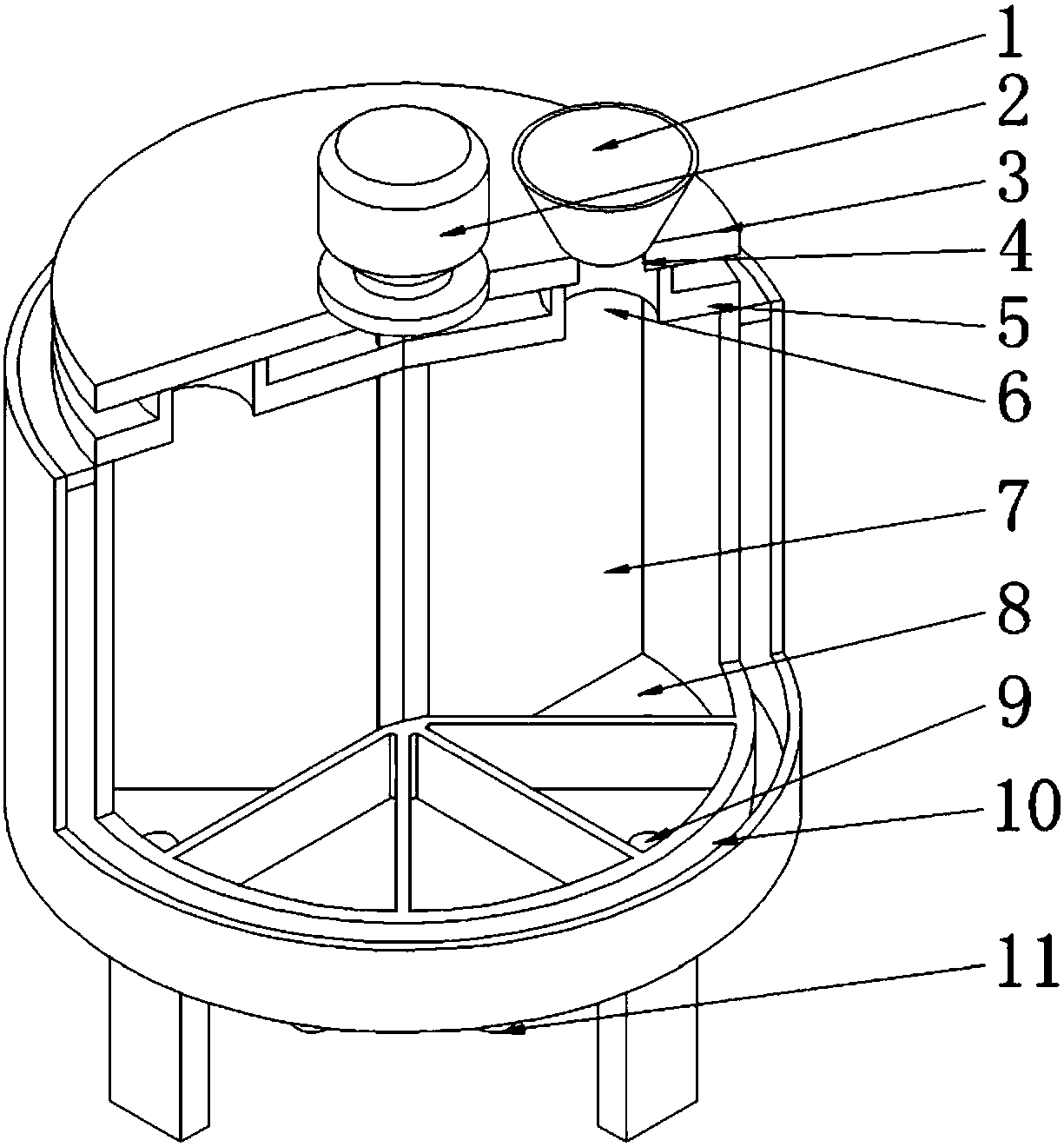

[0016] Embodiment 1 is basically as attached figure 1 Shown: a fermenter for mulberry fermented feed, including a feed hopper 1 and a fermenter, the feed hopper 1 faces the fermenter, the fermenter includes a cover 3 and a cylindrical inner cylinder, and the inner cylinder is equipped with There is a partition 7, and the partition 7 divides the inner cylinder body into eight radially distributed fermentation chambers 8. The bottoms of the eight fermentation chambers 8 are respectively provided with discharge holes 9, and the discharge holes 9 are connected with outlet valves with valves. Feed pipe 11; the top of the inner cylinder body is provided with an inner cover 5, and the position where the inner cover 5 is opposite to the fermentation chamber 8 is provided with an inner layer feed hole 6, and the cover body 3 is sleeved on the outside of the inner cylinder body and connected to the inner cylinder body. The cylinder is rotationally connected, the middle part of the cover...

Embodiment 2

[0018] The difference between embodiment 2 and embodiment 1 is only that fermentation chamber 8 is set to twelve, and heating wire is contained in gap 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com