Stair-stepping electrostatic spinning spray nozzle and electrostatic spinning method thereof

An electrospinning, step-like technology, applied in the field of step-like electrospinning nozzles and electrospinning, can solve the problems of increased manufacturing costs, unsuitable products, poor spinning effect, etc., to improve stability and service life , reduce equipment damage, and avoid the effect of uneven spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention rather than limit the protection scope of the present invention. Within the spirit of the invention of the present invention and the protection scope of the claims, any amendments and changes made to the present invention will fall within the protection scope of the present invention. protection scope of the invention.

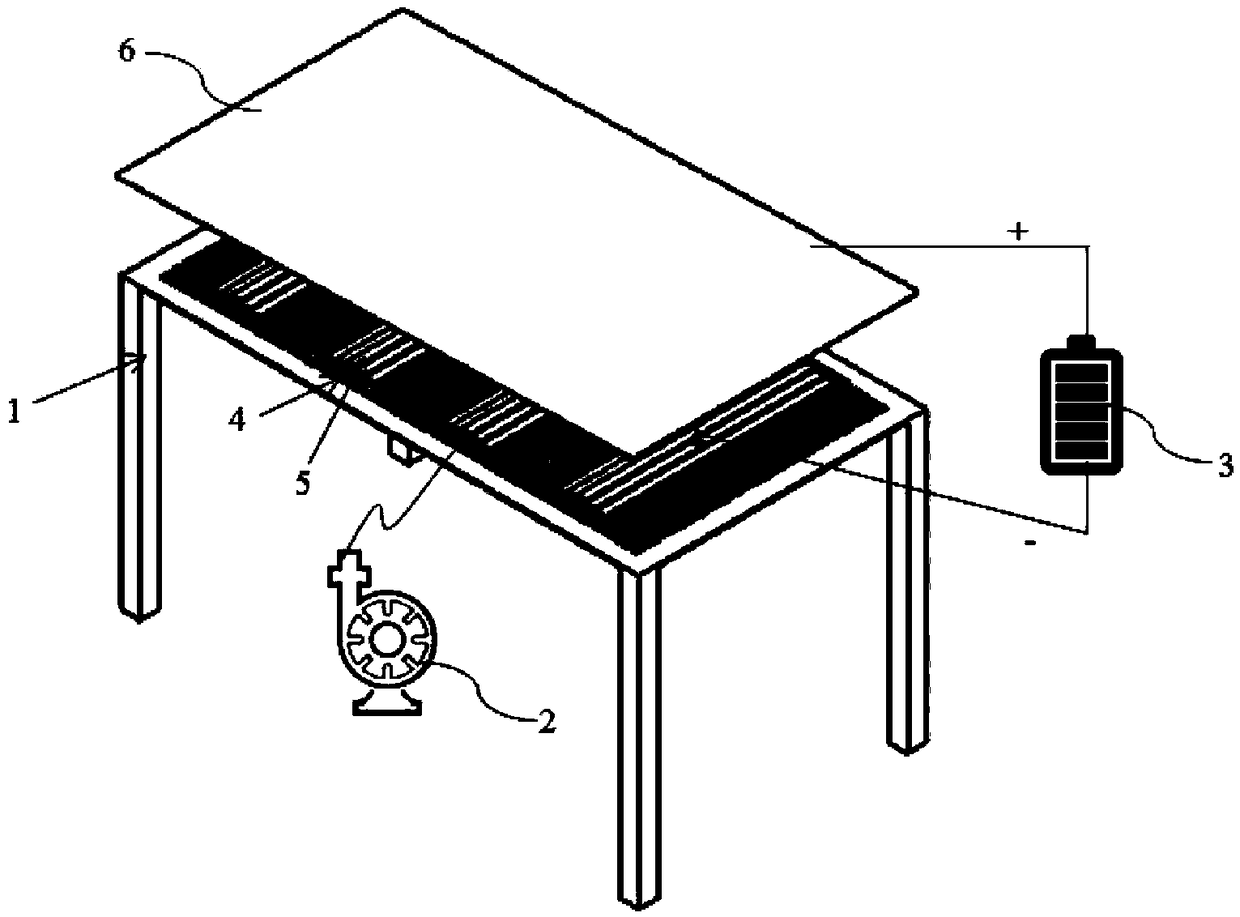

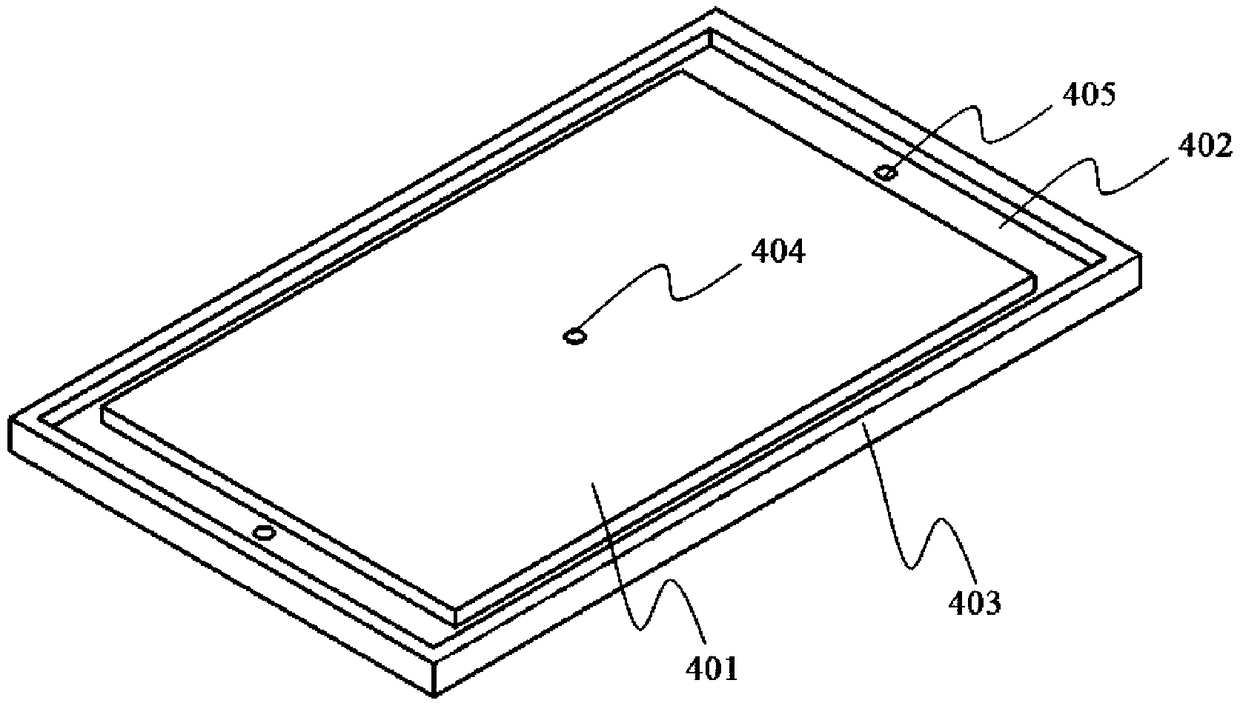

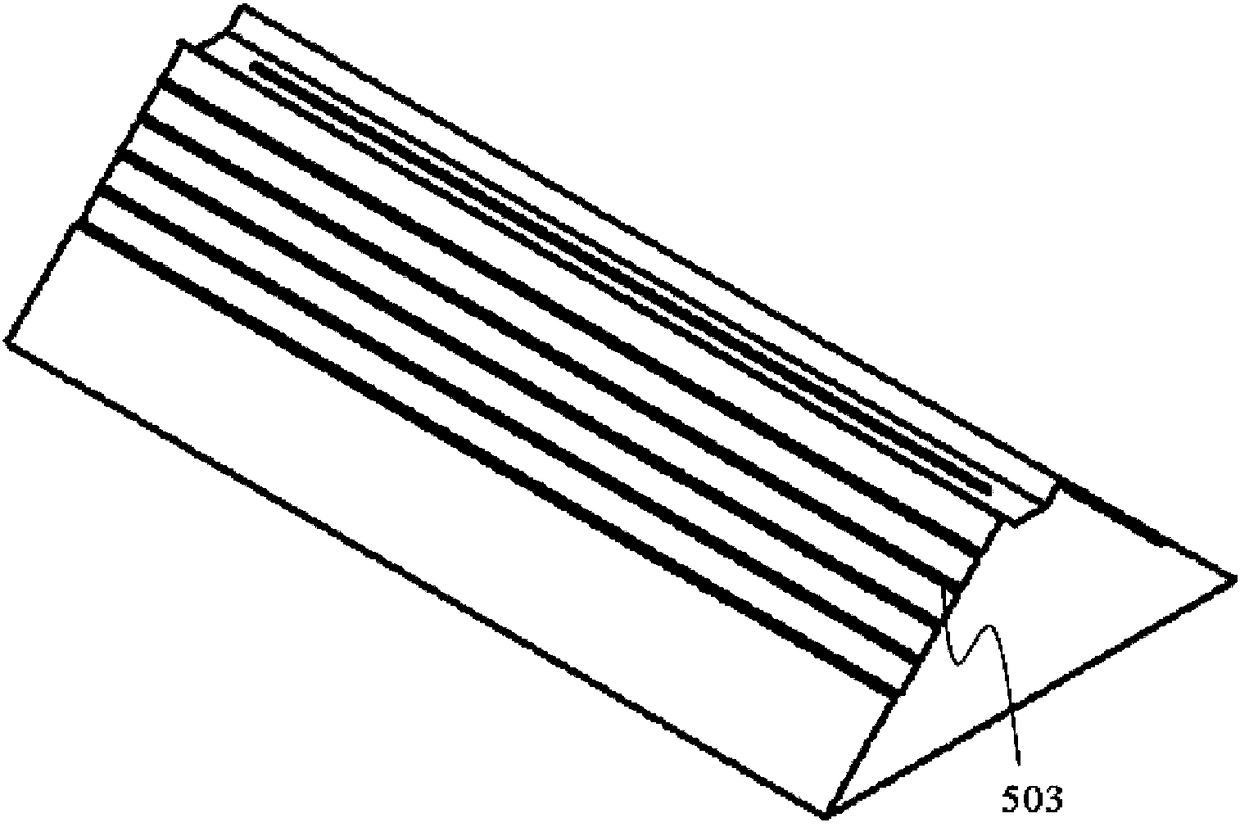

[0038] like figure 1 As shown, a ladder-shaped electrospinning nozzle includes a workbench 1, an infusion pump 2, a high-voltage electrostatic generator 3, a collection tank 4, a spinneret 5, and a receiving plate 6; wherein, the infusion pump 2, the high-voltage electrostatic generator 3 are external devices; the workbench 1 is composed of a horizontally placed table top and four support feet perpendicular to the table top, and the four support feet are res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com