Manufacturing process of multifunctional coating cloth

A multi-functional coating and production process technology, applied in conductive coatings, liquid repellent fibers, textiles and papermaking, etc. Improve product quality, increase production efficiency, and avoid the effect of cross-process turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

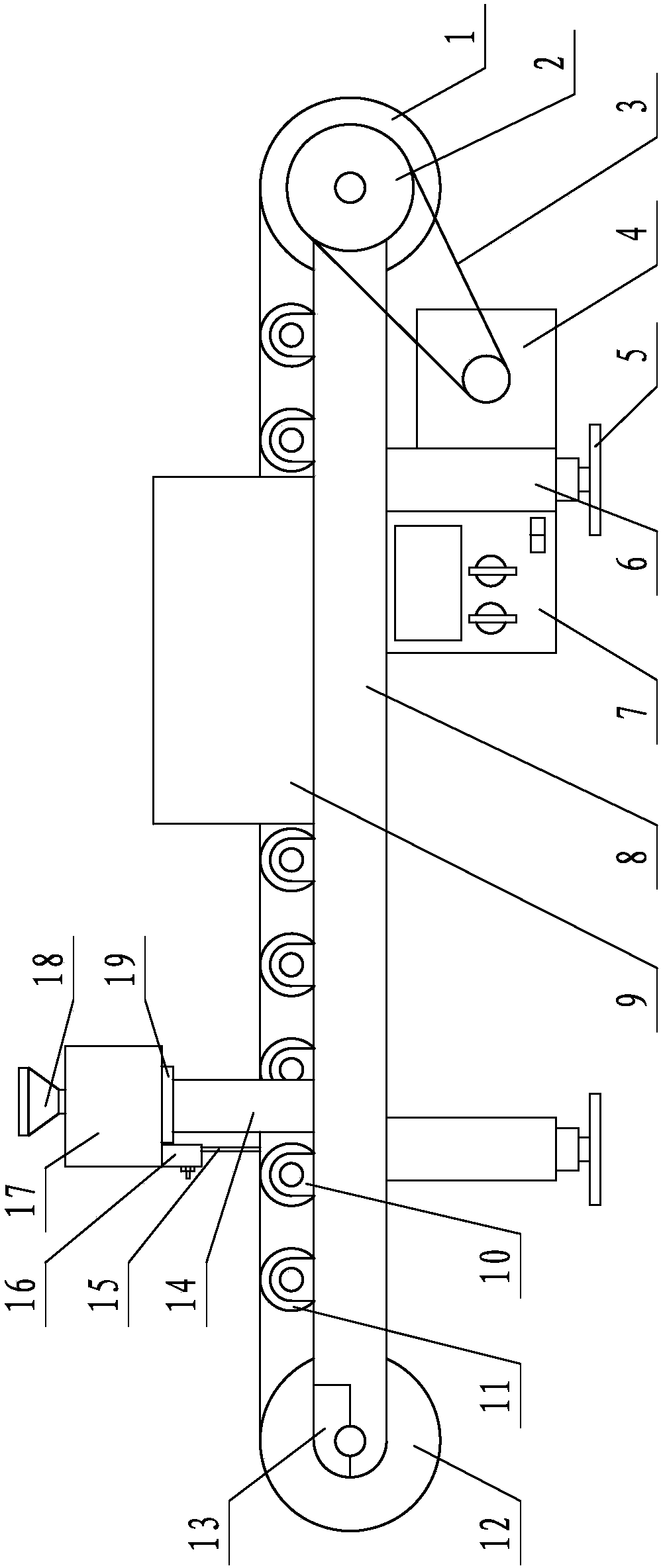

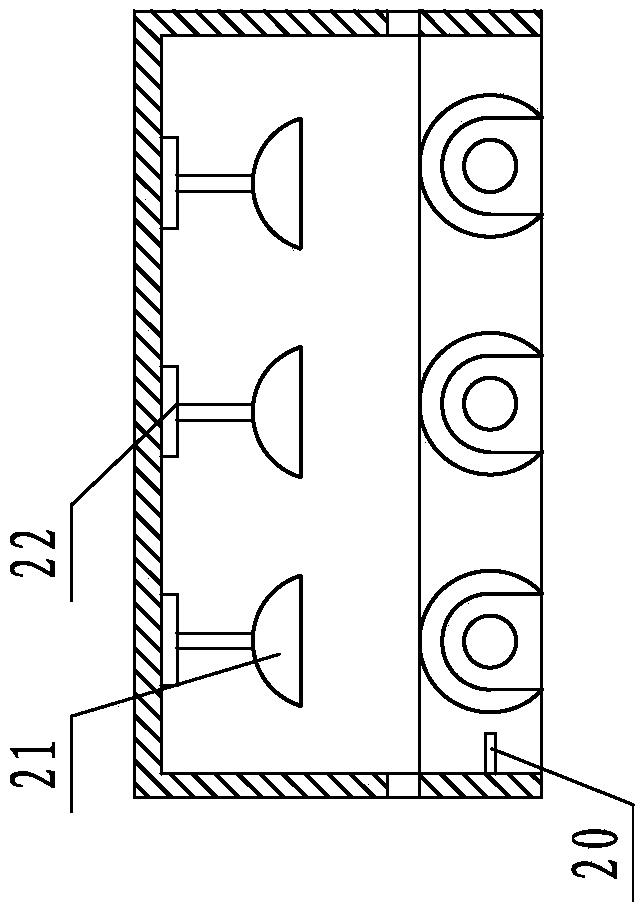

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

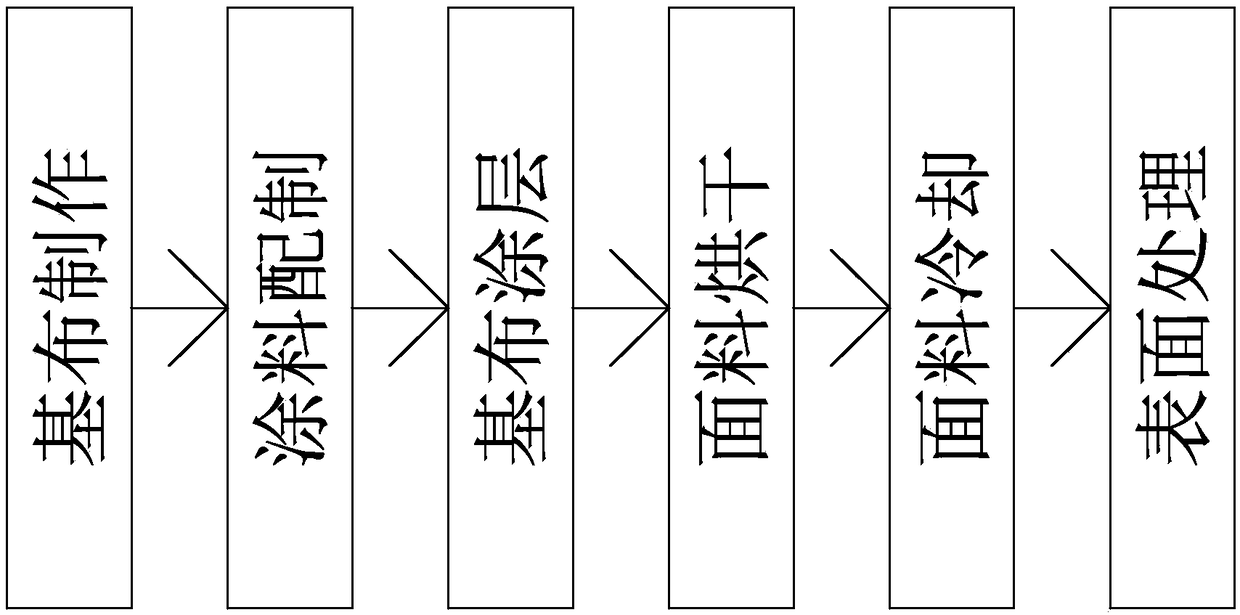

[0030] like Figure 1-4 Shown, a kind of manufacturing process of multifunctional coated cloth, this manufacturing process comprises the following steps:

[0031] S1. Production of base fabric: woven with 75D high-strength polyester yarn;

[0032] S2, paint preparation: the paint is made of PVC resin powder from the following raw materials in parts by weight, soybean oil 5-7, titanium dioxide 6-8, calcium carbonate 30, stabilizer 2-4, antiaging agent 2-6, antistatic agent 1-3;

[0033] S3, base cloth coating: put the coating in S2 into a coating device for coated cloth, and coat the base cloth in S1 through this coating device for coated cloth to obtain a semi-finished coated cloth;

[0034] S4. Fabric drying: drying th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com