Patents

Literature

40results about How to "Antistatic has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cation dyeable compound functions

InactiveCN102391486AAvoid self-polymerizationEasy-to-stain function guaranteeMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a preparation method for polyester fibers with anti-static, anti-pilling and normal-pressure cationic dyeable compound functions. The preparation method comprises procedures of primary esterification, transesterification, secondary esterification and polymerization, wherein three monomers are added in the transesterification procedure; a hindered amine light stabilizer, a hindered phenol antioxidant and hydroxyl silicon oil are added after the secondary esterification and before prepolymerization; and an antistatic agent is added after the prepolymerization and before final polymerization. Fabric spun by the polyester fibers has high anti-static and anti-pilling properties; the polyester fibers can be dyed with various bright colors due to the normal-pressure cation dyeable property; the unified requirement of high-grade spring and summer clothing at present on functionality and color is met; and the fibers and wool can be dyed in the same bath and a good clothing effect of the fibers blended with the wool is achieved. The polyester fibers are important supplement for the cation dyeable polyester fiber market at present and have wide market prospect.

Owner:WUJIANG GANGYANG CHEM FIBER +1

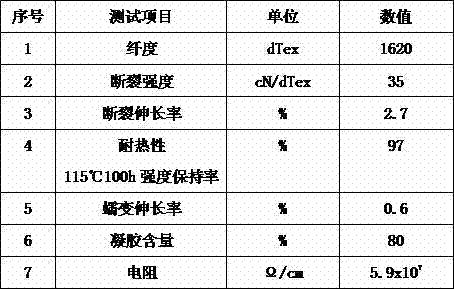

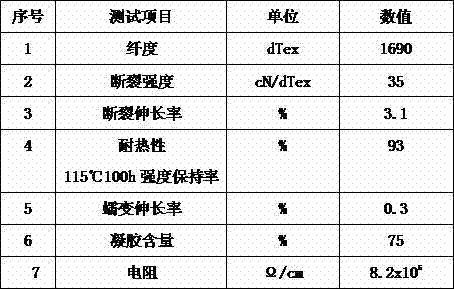

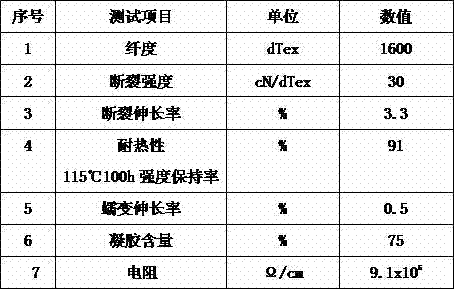

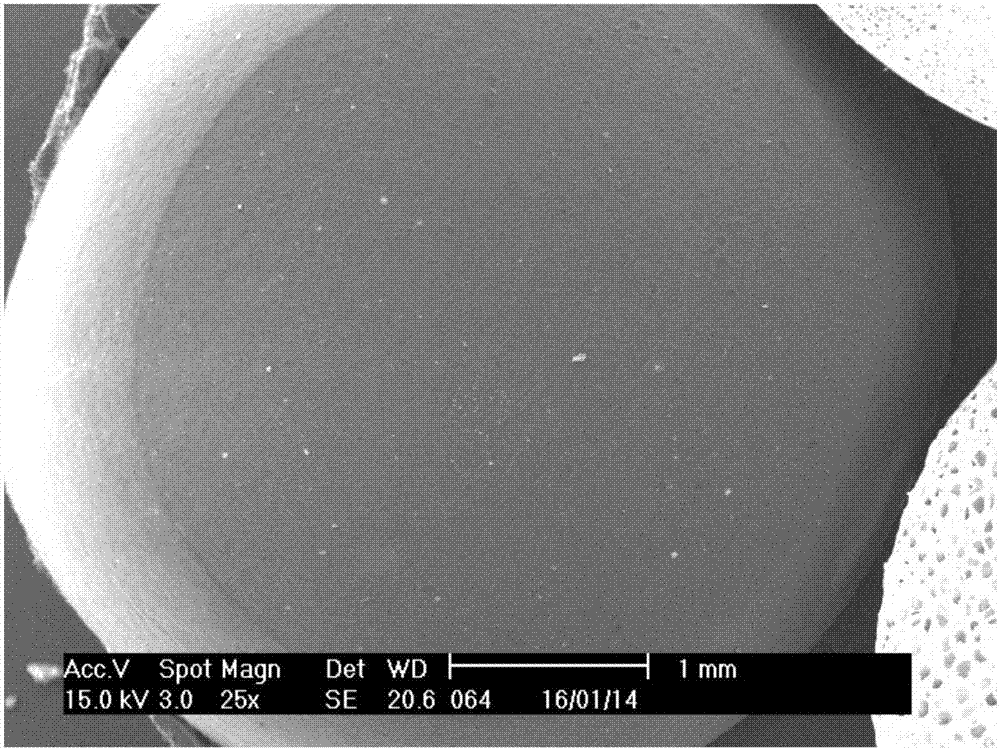

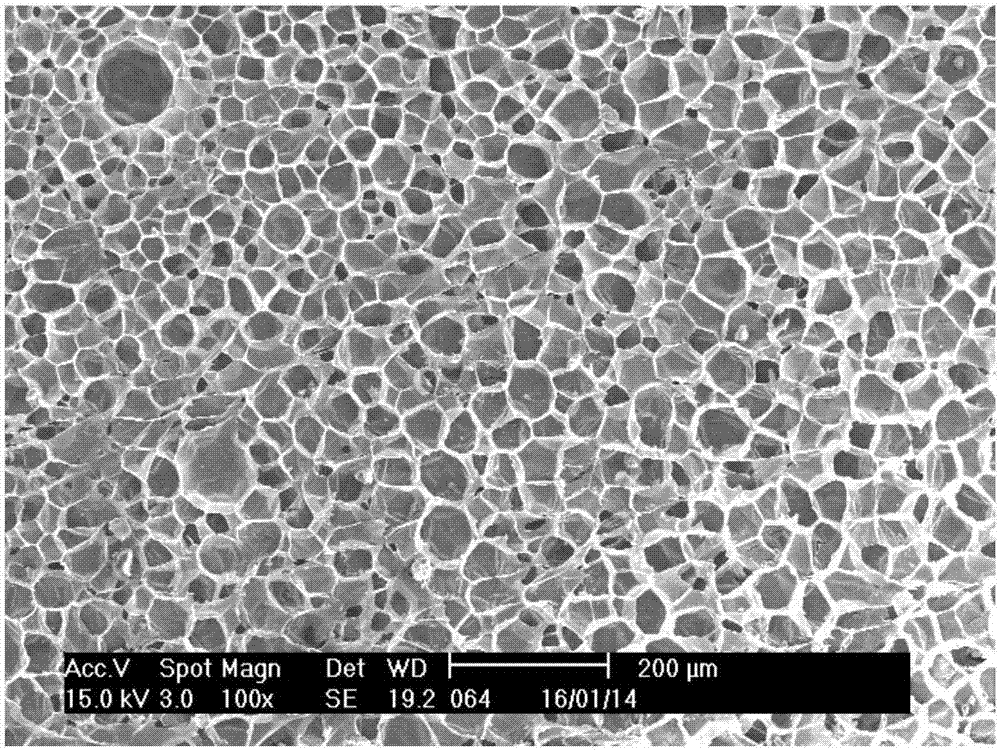

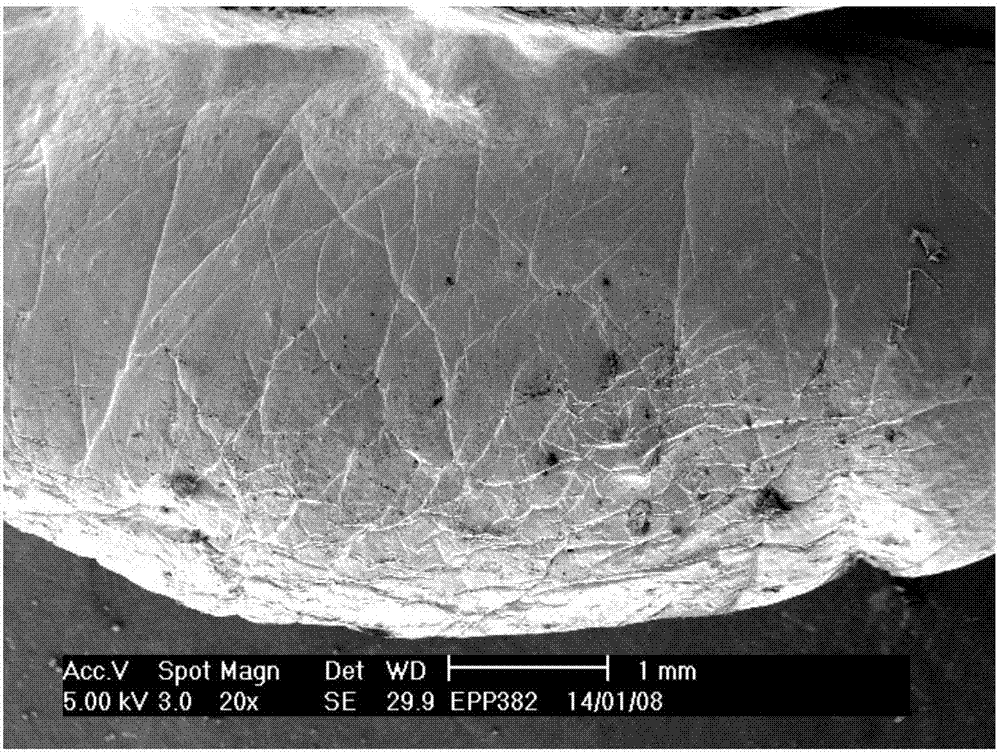

Heat-resisting antistatic UHMWPE (ultra high molecular weight polyethylene) fiber and preparation method thereof

InactiveCN104711696AHeat resistantHeat-resistant and anti-staticElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentCross-linkFiber

The invention provides a heat-resisting antistatic UHMWPE (ultra high molecular weight polyethylene) fiber and a preparation method thereof. The fiber includes UHMWPE powder, nano conductive particles, a cross-linking agent, a curing agent, an initiator and an antioxygen. The preparation method includes the following steps: the UHMWPE powder swells through a solvent and holes are formed; then a composite modifying agent formed through jointly soaking the cross-linking agent, the curing agent, the initiator, the antioxygen, the nano conductive particles and the solvent is added, and uniformly permeates the holes in the UHMWPE powder; after uniform mixing, spun silks are extruded out through a screw extruder; and the UHMWPE fiber is obtained through drafting after the solvent is removed; the heat-resisting antistatic UHMWPE fiber is obtained through irradiation crosslinking. The heat-resisting antistatic UHMWPE fiber has the comprehensive performance of wear resistance, heat resistance, static resistance, shock resistance, self-lubrication, corrosion resistance, low temperature resistance, sanitary and non-poisonous performance, less possibilities of adhesion and water absorption, small density and the like, is wide in application range and long in service life.

Owner:JIANGSU SHENTAI SCI & TECH DEV

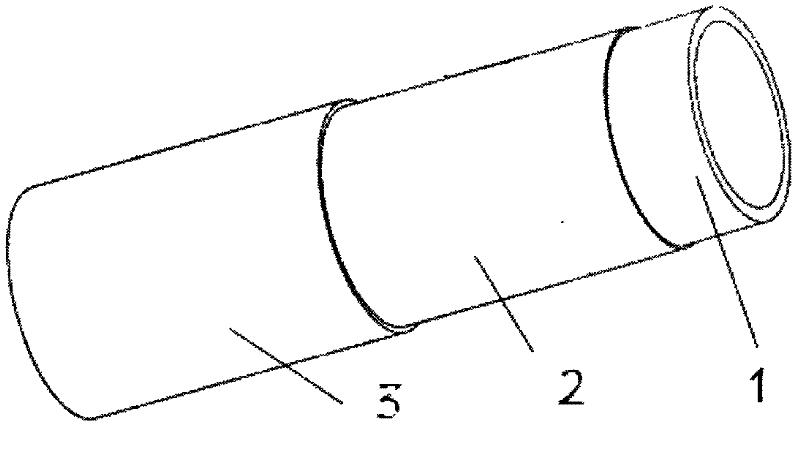

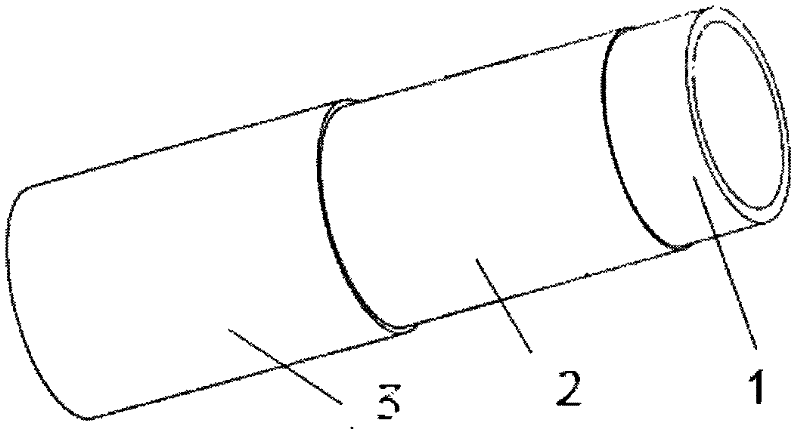

High-strength flame-retardant anti-static pipeline

InactiveCN102506240AHigh crystallinityHigh degree of interface adhesionSynthetic resin layered productsRigid pipesPolymer scienceAcrylonitrile

The invention provides a high-strength flame-retardant anti-static pipeline comprising an inner layer, a combined layer and an outer layer, wherein the inner layer contains the following proportional components: 600 to 800 parts of high-density polyethylene by weight, 5 to 15 parts of glass fibre by weight, 1 to 2 parts of wollastonite by weight, 1 to 6 parts of ethylene-propylene diene copolymer by weight, 4 to 9 parts of butadiene-acrylonitrile rubber by weight, 3 to 6 parts of styrene-butadiene-styrene terpolymer copolymer by weight, 9 to 13 parts of nano carbon tube by weight, 10 to 30 parts of polypropylene grafted maleic anhydride by weight, 15 to 25 parts of flame retardant by weight and 13 to 19 parts of graphitized carbon black by weight; the outer layer contains the following proportional components: 300 to 500 parts of medium-density polyethylene by weight, 12 to 21 parts of flame retardant by weight and 9 to 13 parts of graphitized carbon black by weight; and the main component of the combined layer is hot melting glue. The pipeline provided by the invention has favorable performances of heat insulation and flame retardant; meanwhile, the pipeline also has higher toughness; and furthermore, the erosion resistance, the high-pressure resistance and the rigidity performance are high.

Owner:ZHEJIANG NORMAL UNIVERSITY

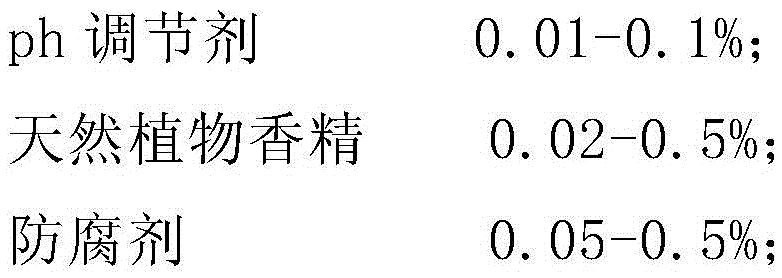

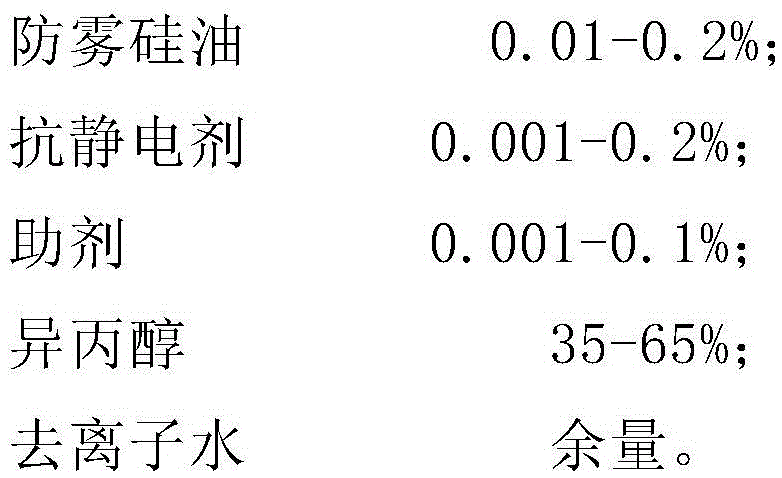

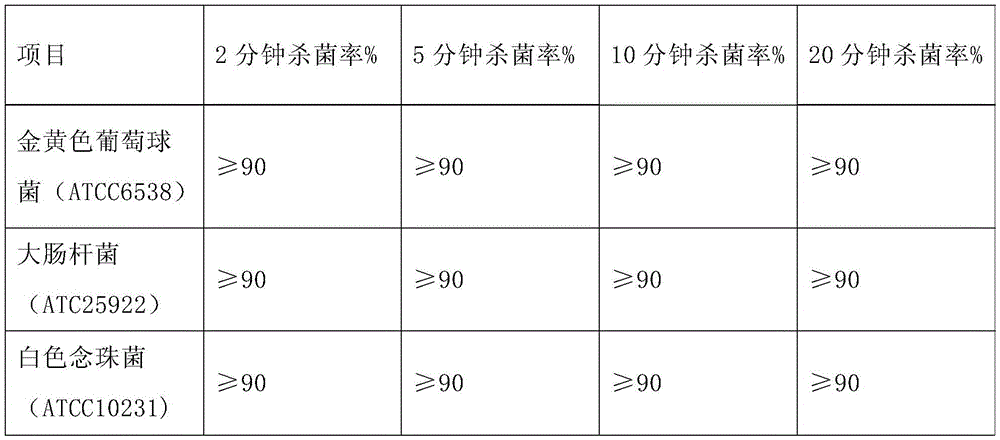

Lens cleaning towel

InactiveCN105419979AEasy maintenanceAntistatic hasDetergent materialsOrganic non-surface-active detergent compositionsAntistatic agentPreservative

The invention discloses a lens cleaning towel which comprises a base material and a cleaning agent immersed into the base material. The cleaning agent is prepared from a ph adjusting agent, a natural plant essence, preservative, anti-fog silicone oil, an antistatic agent, an assisting agent, isopropanol and deionized water. The lens cleaning towel has the advantages of resisting static electricity, preventing and killing bacteria, preventing fog, being dried rapidly, being free of mark, producing no damage to a lens, having the natural plant fragrance and the like. The service life of the lens can be effectively prolonged, and the effect of well maintaining the lens is achieved.

Owner:SHANGHAI YINJING MEDICAL SUPPLIES

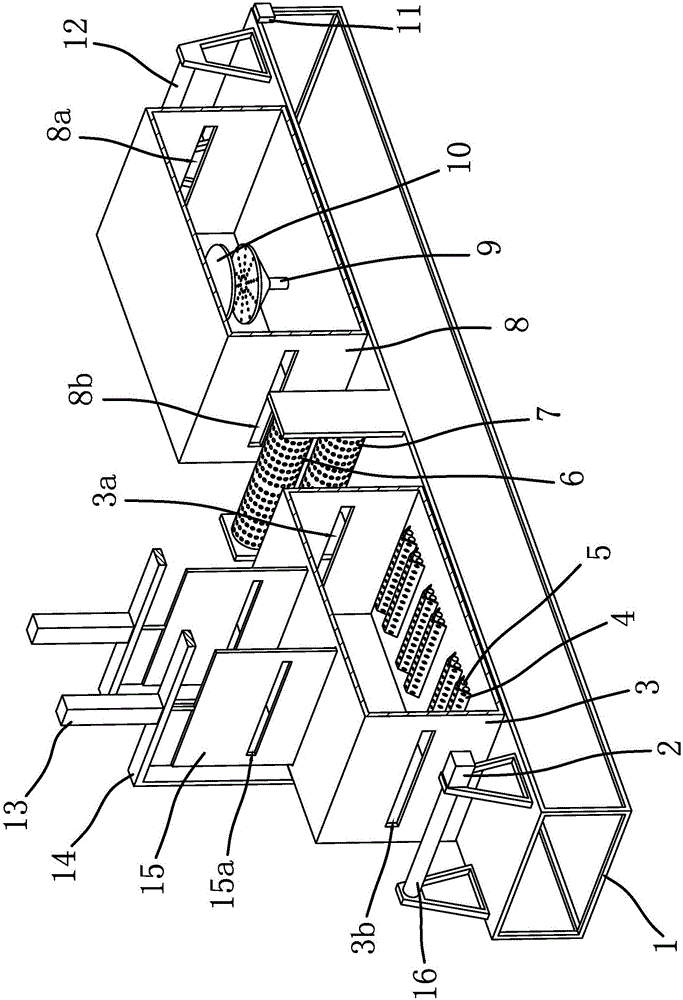

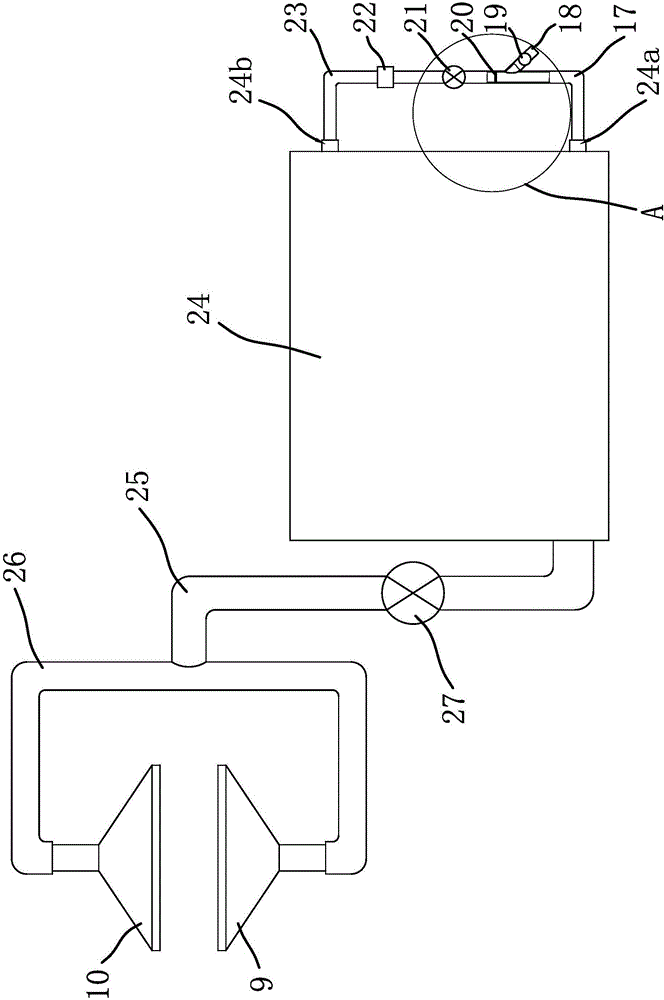

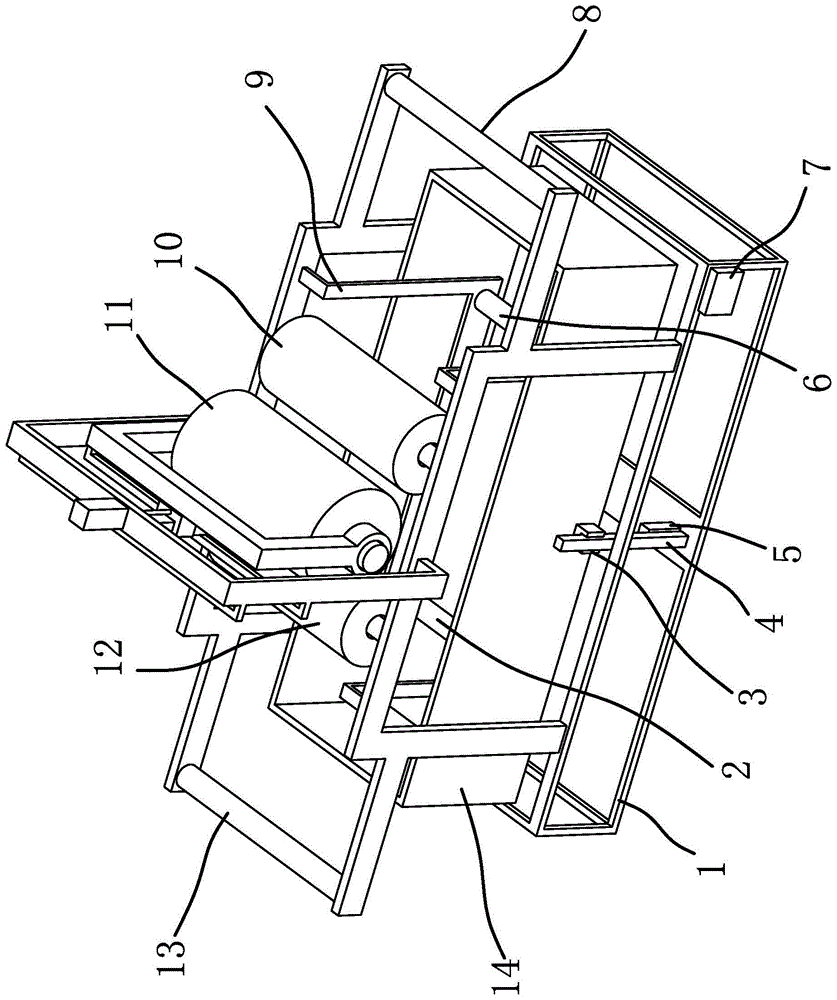

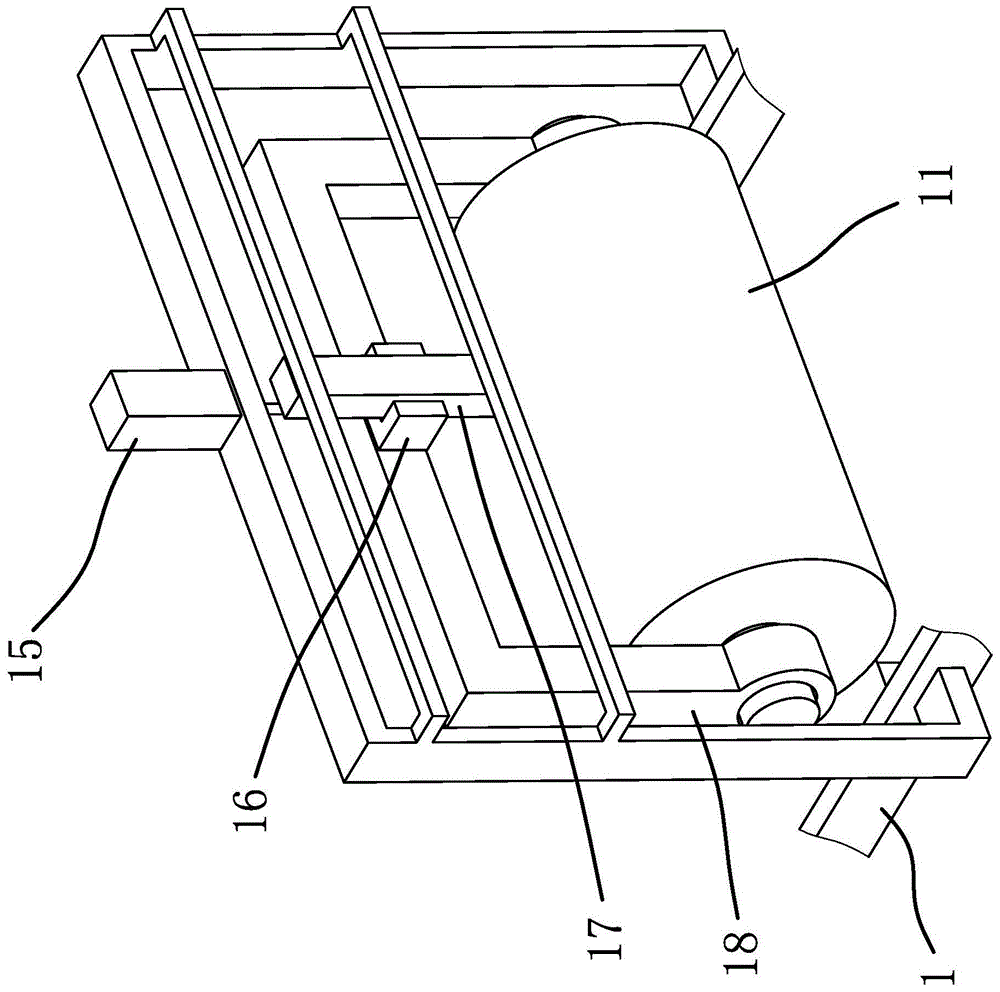

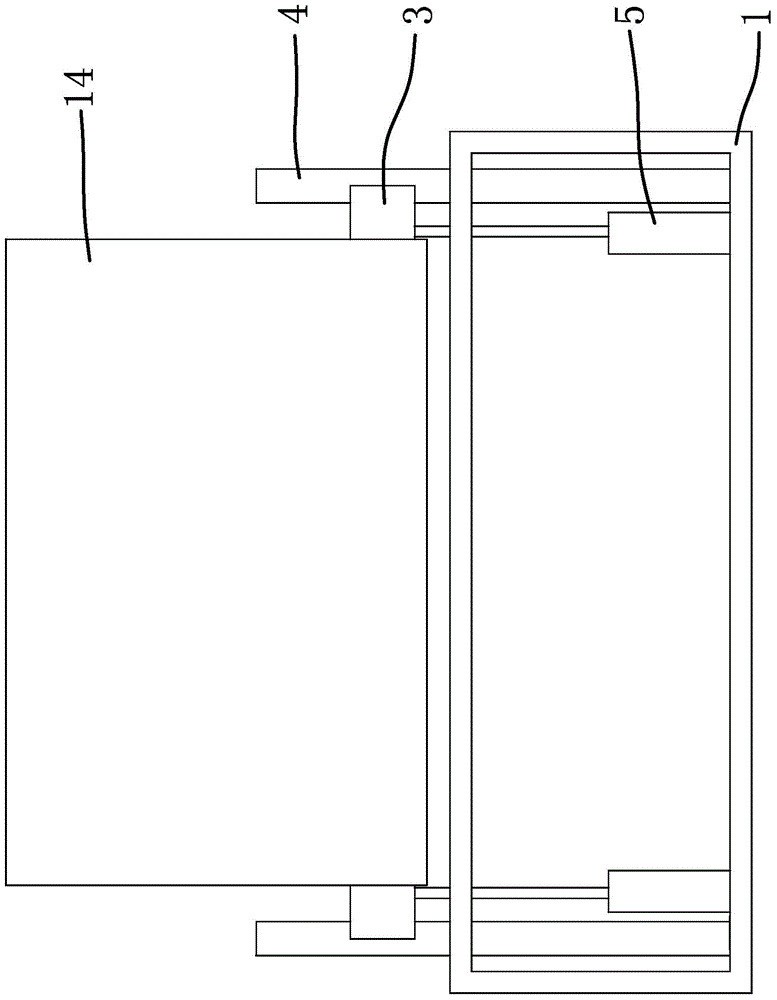

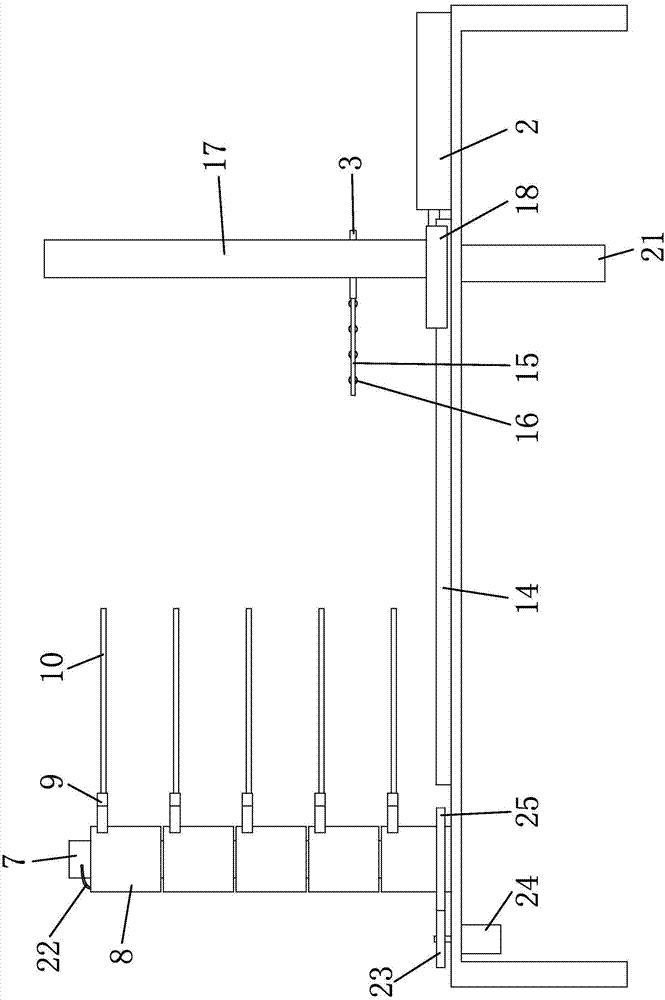

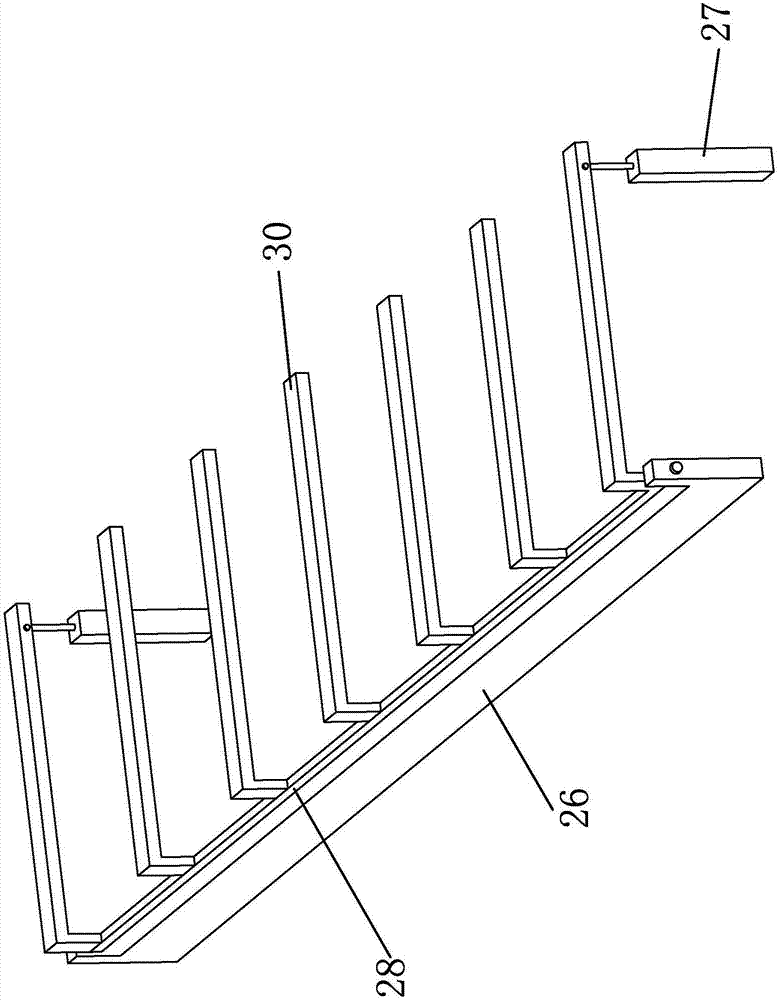

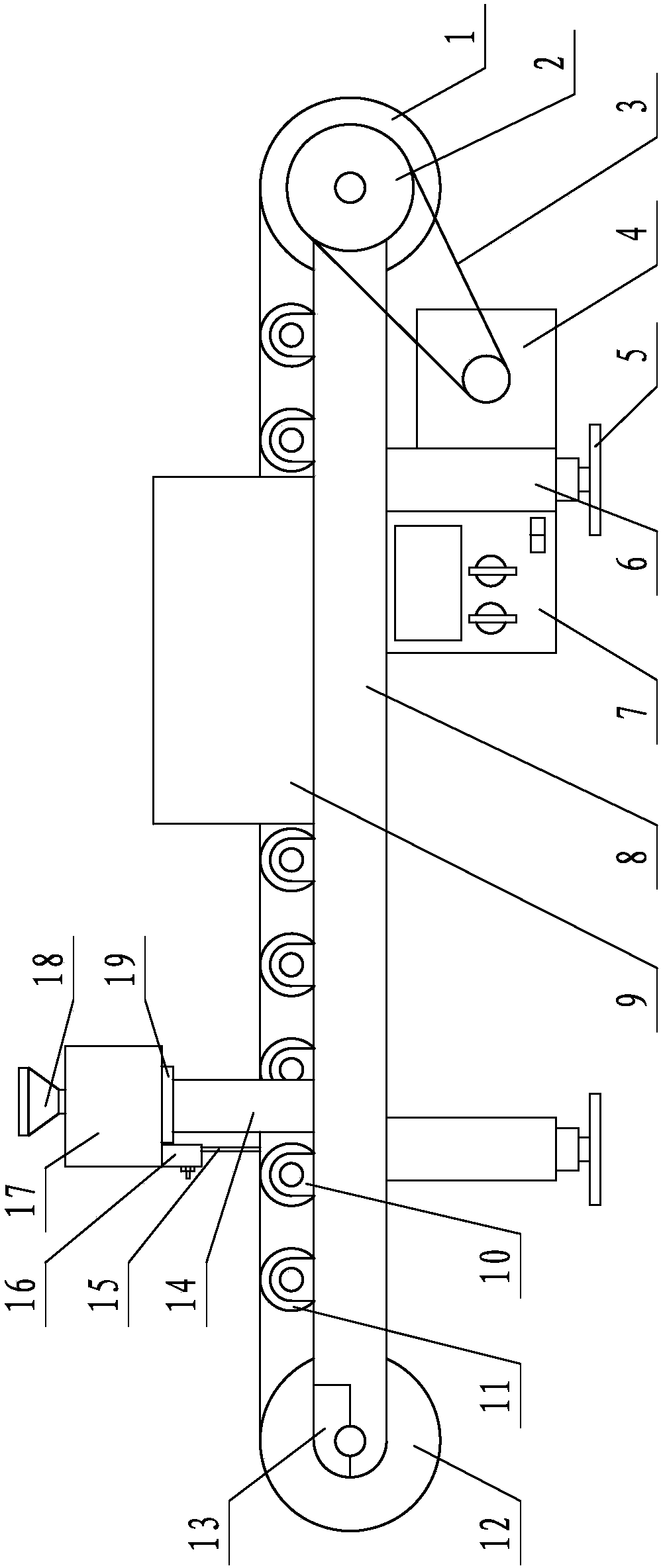

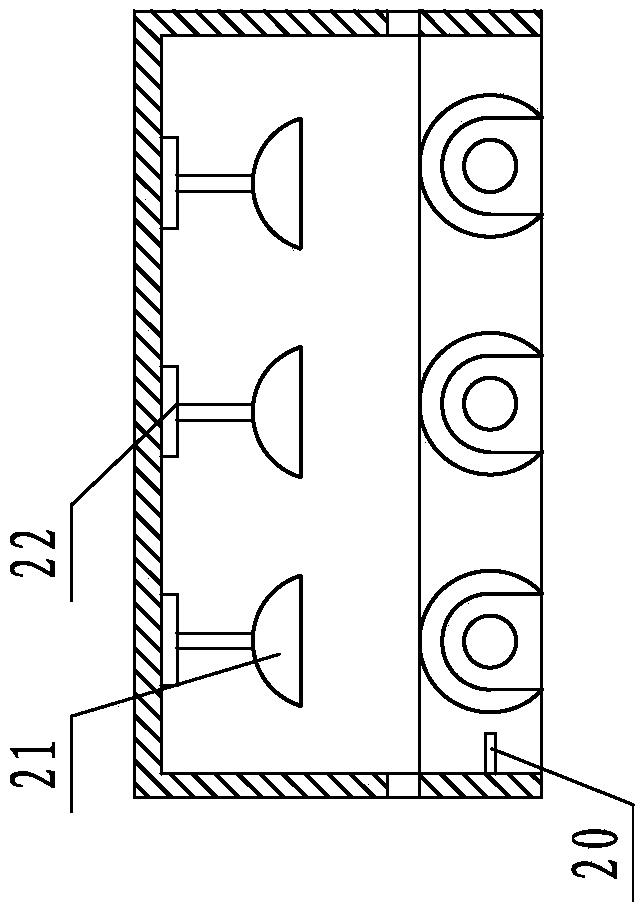

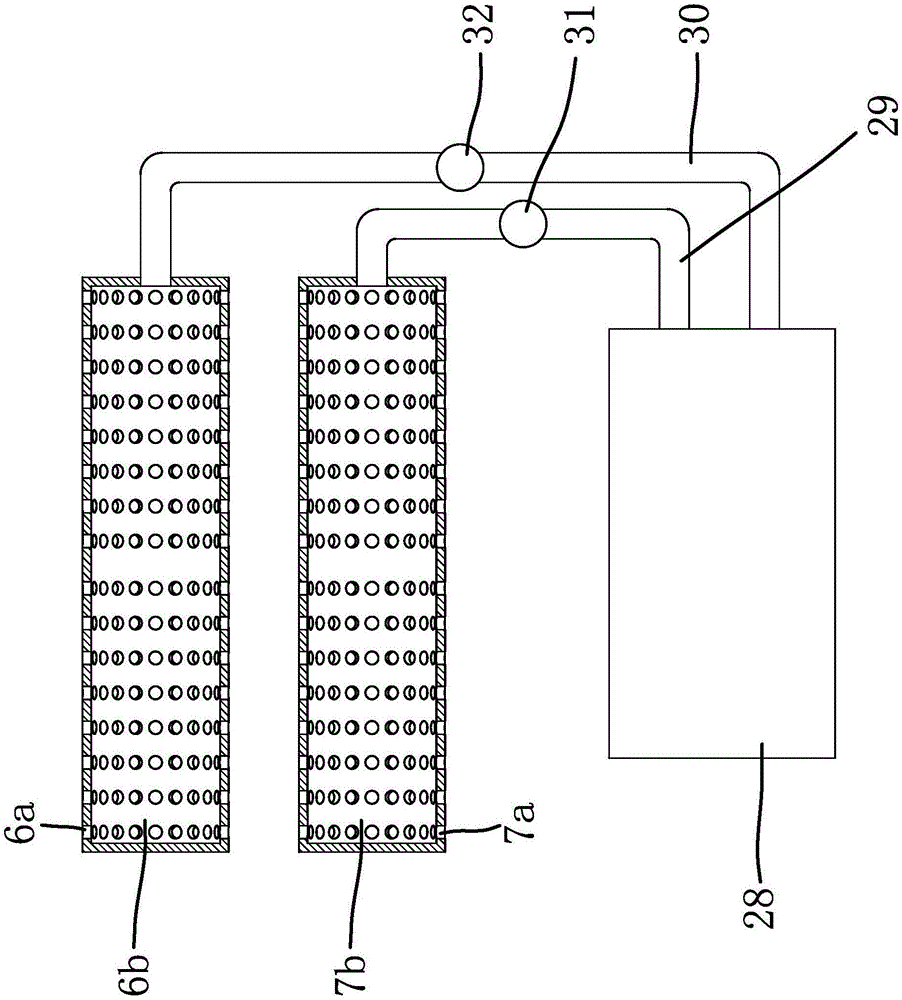

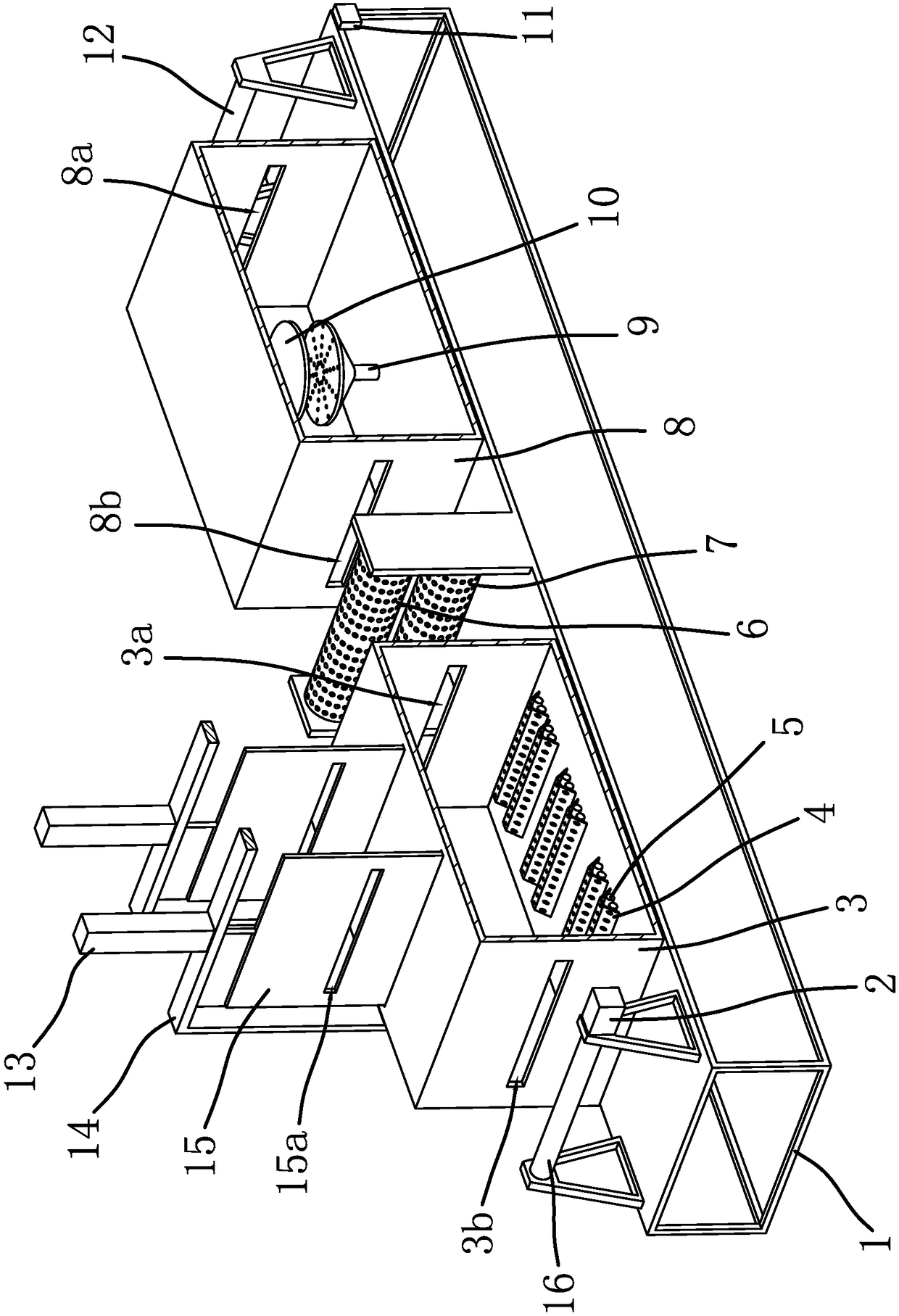

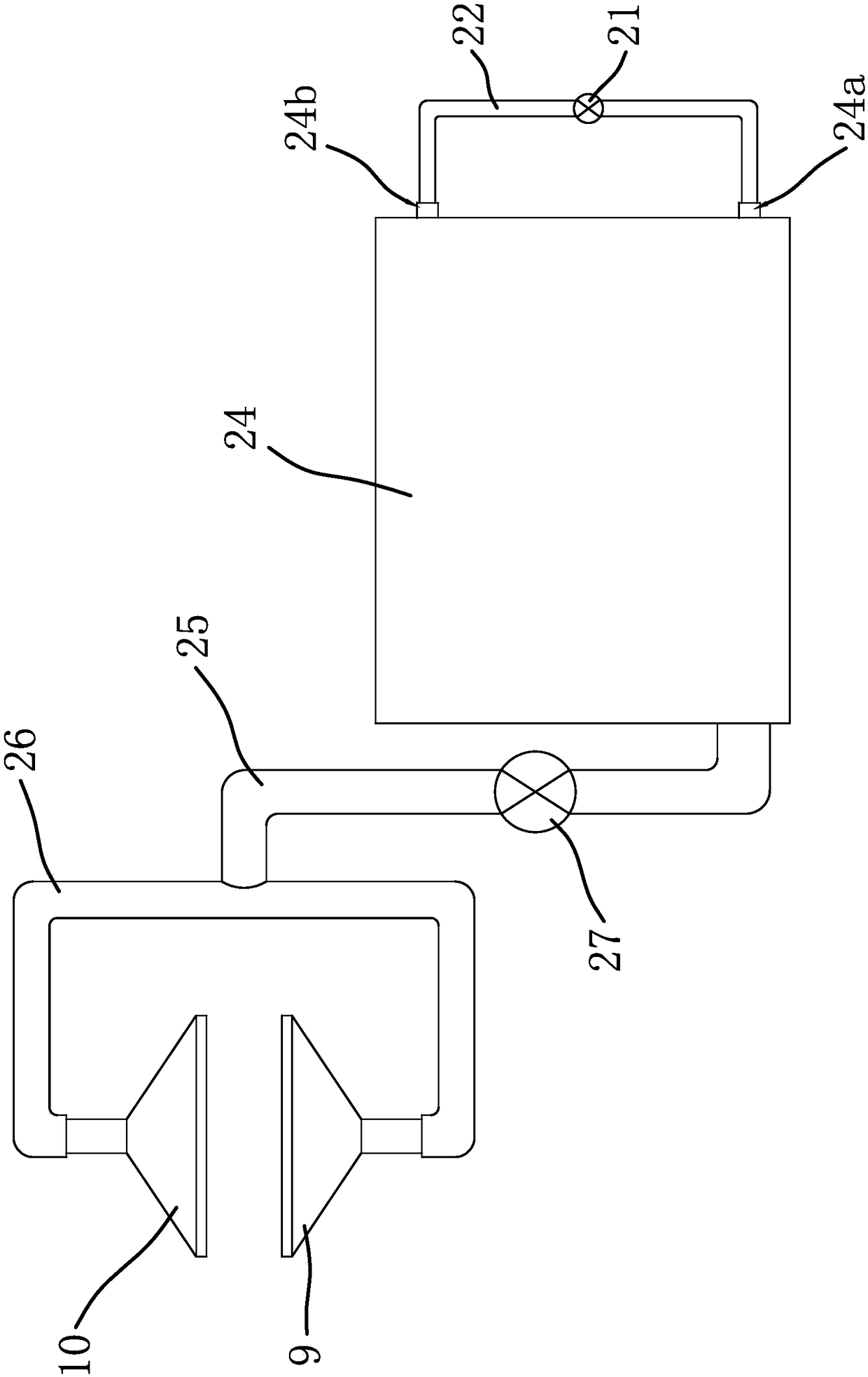

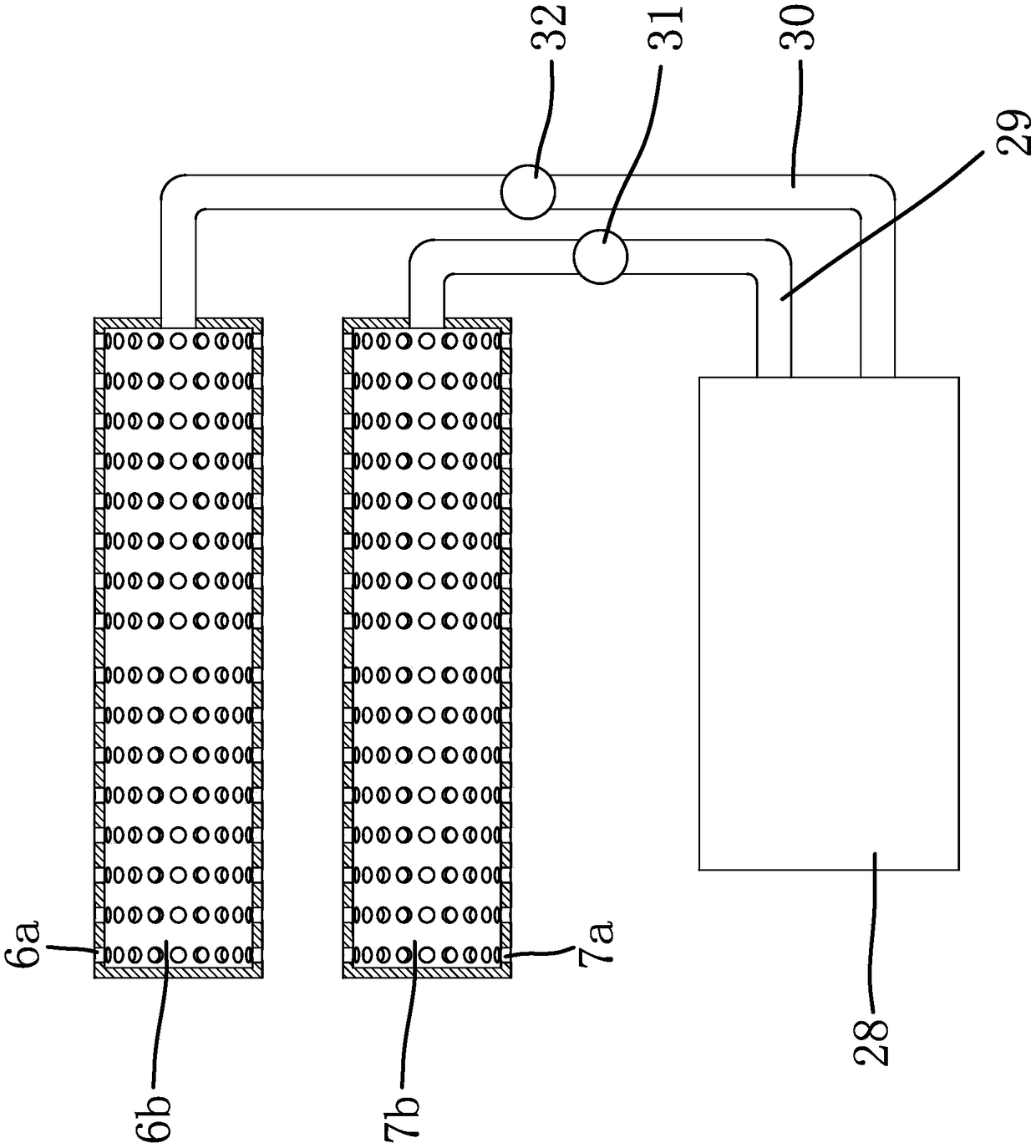

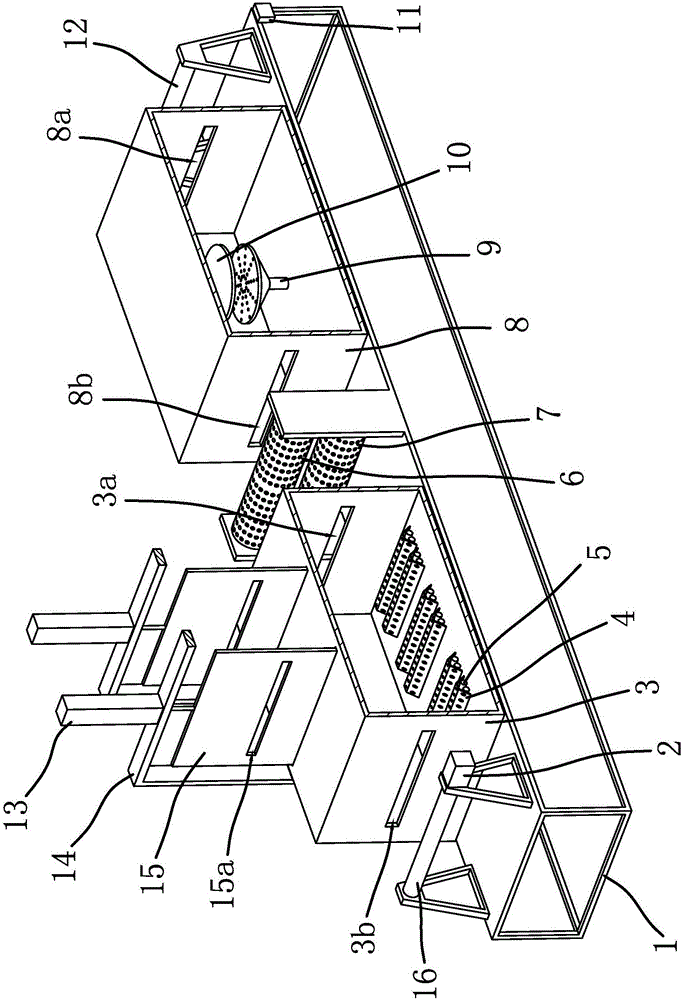

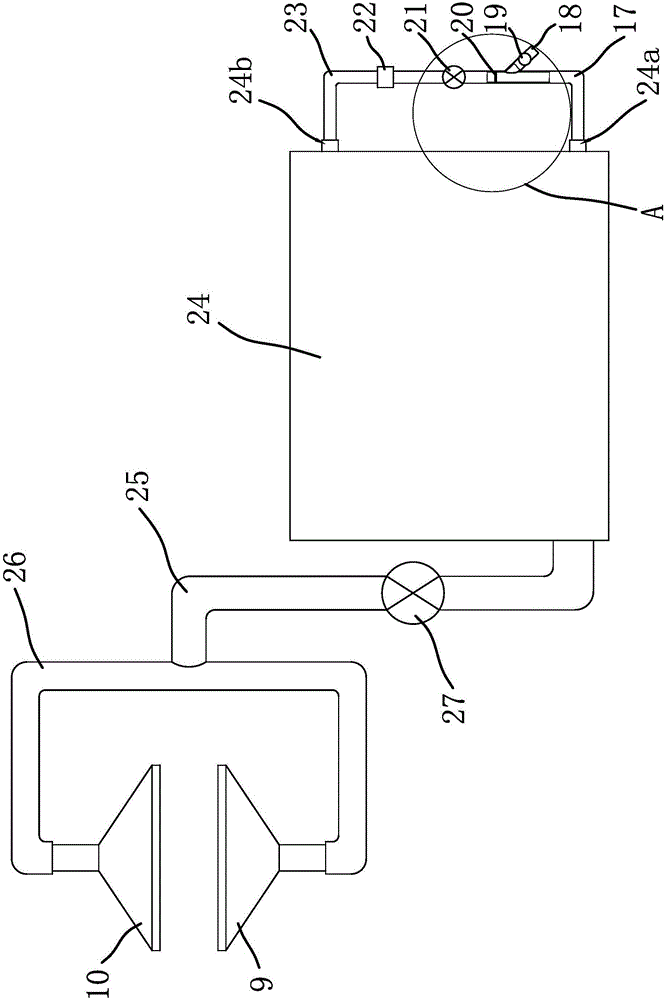

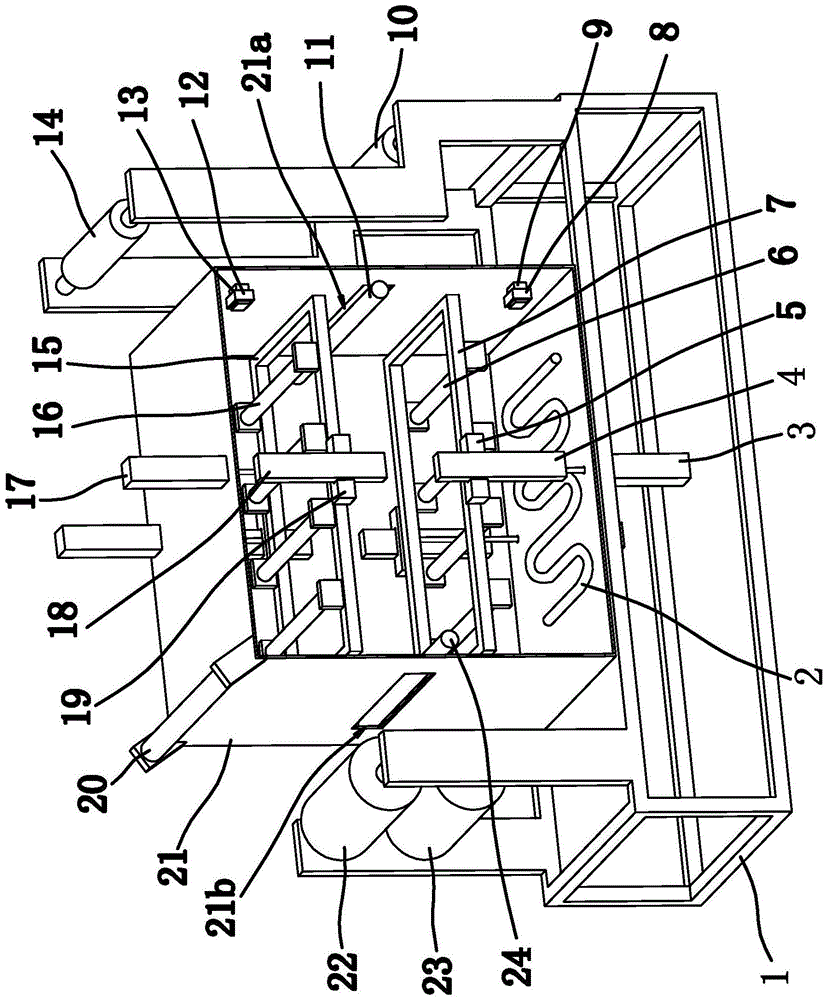

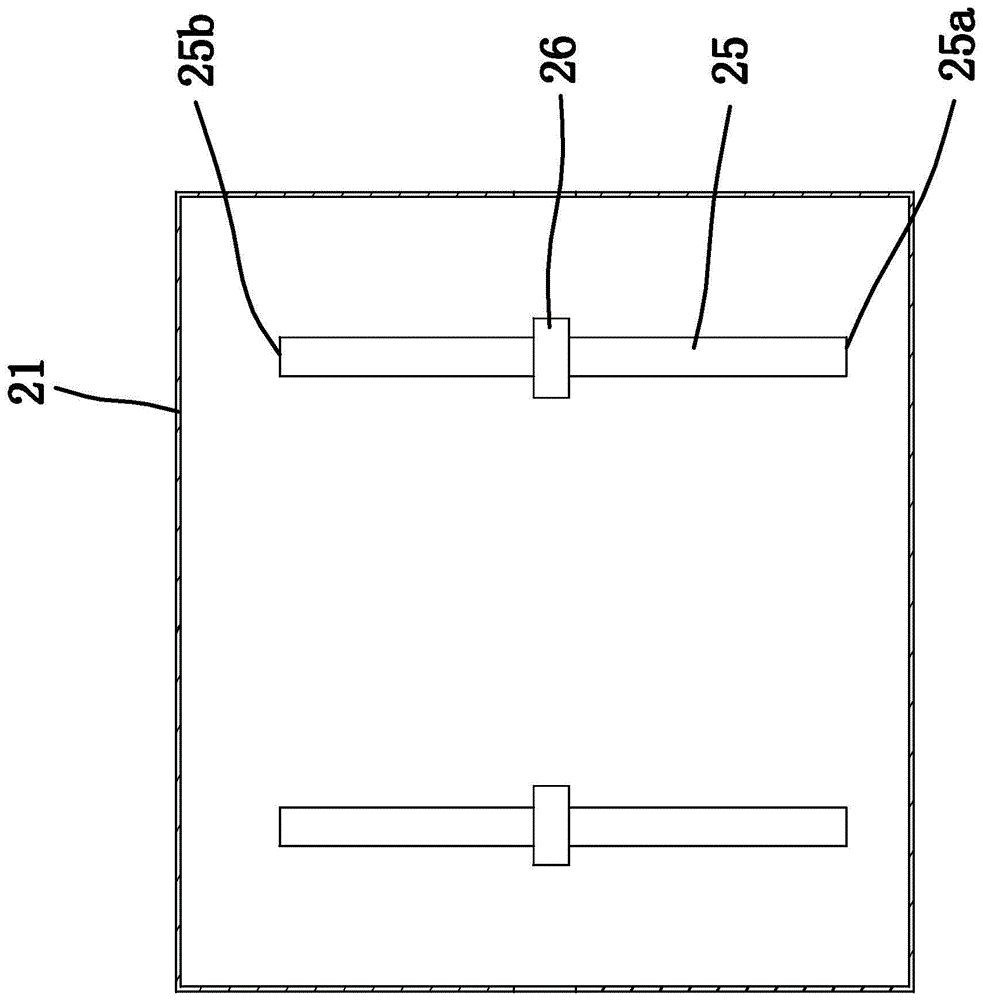

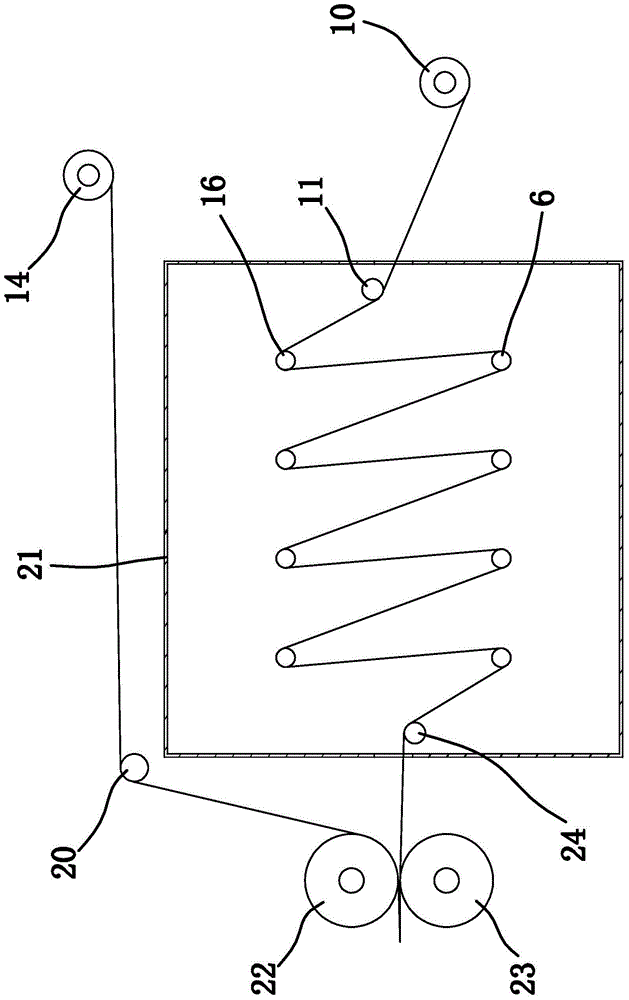

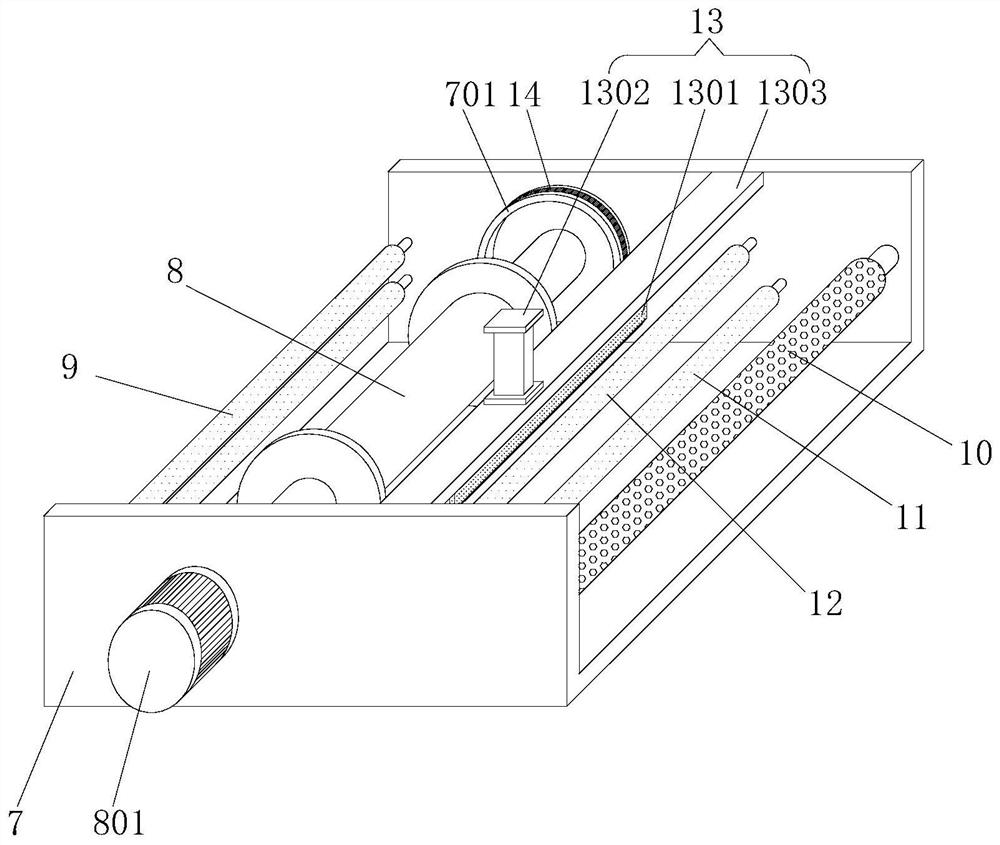

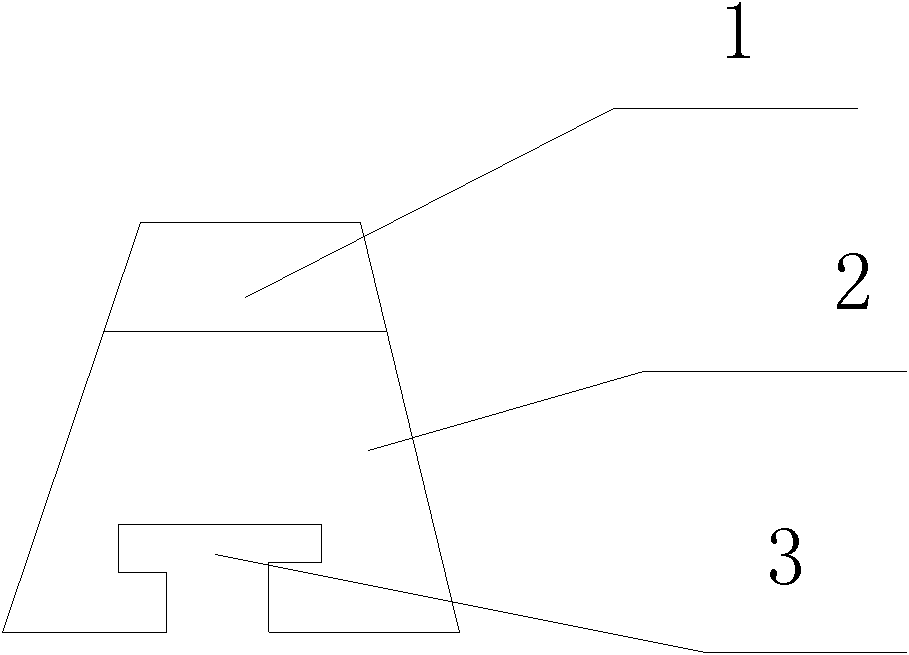

Spraying and drying equipment for ultrafine aramid fiber needle-punched filter bag

ActiveCN106391386AAntistatic hasCorrosion resistanceDispersed particle filtrationSpraying apparatusAramidMechanical engineering

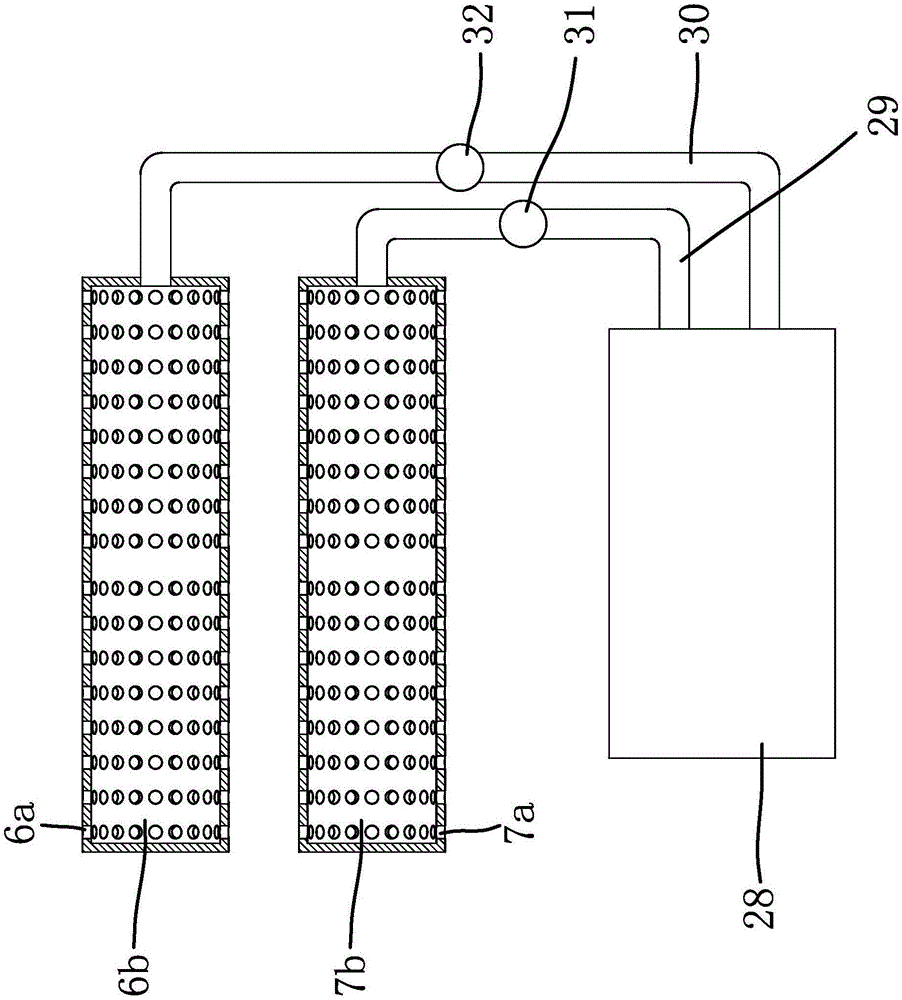

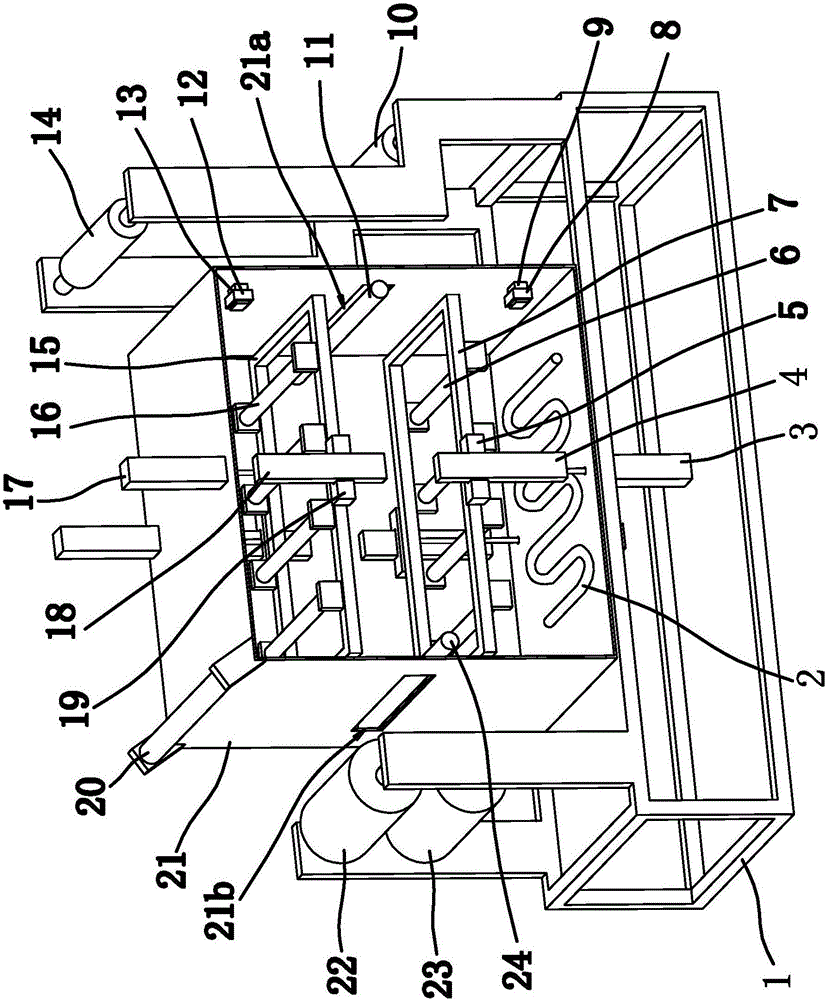

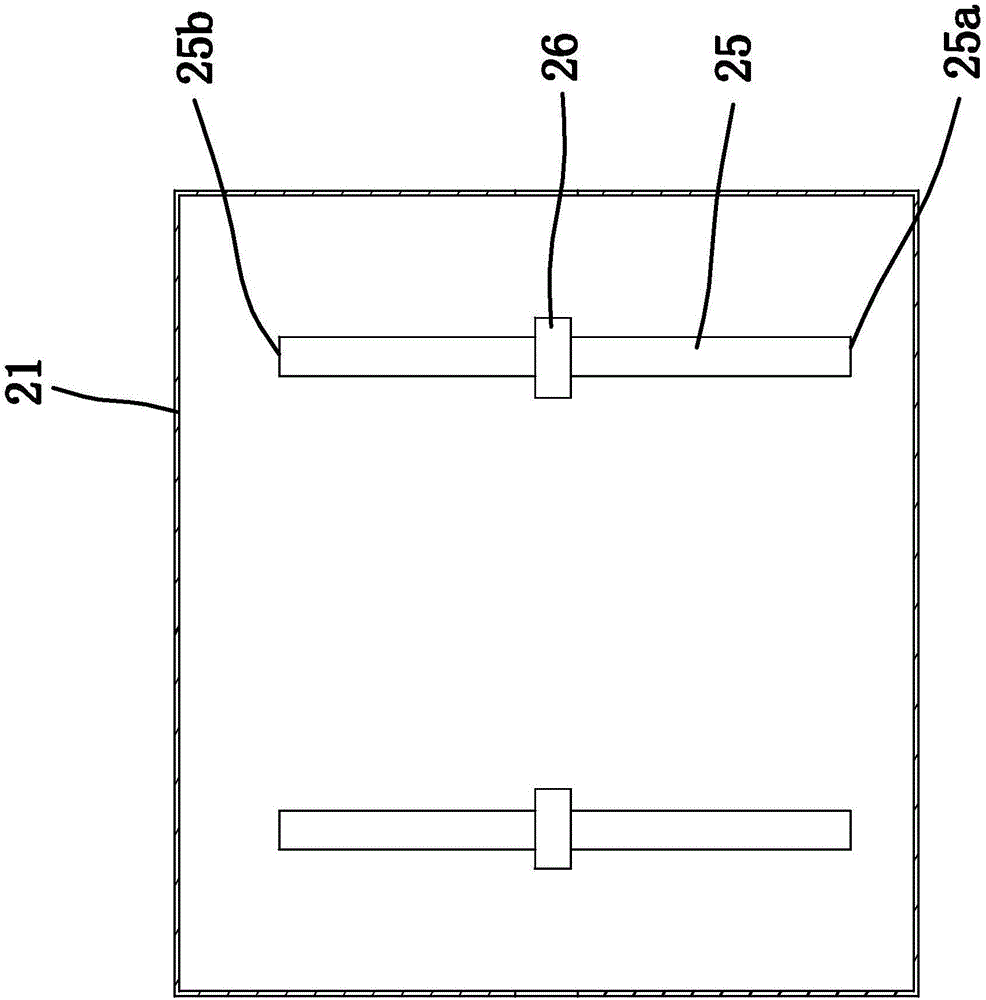

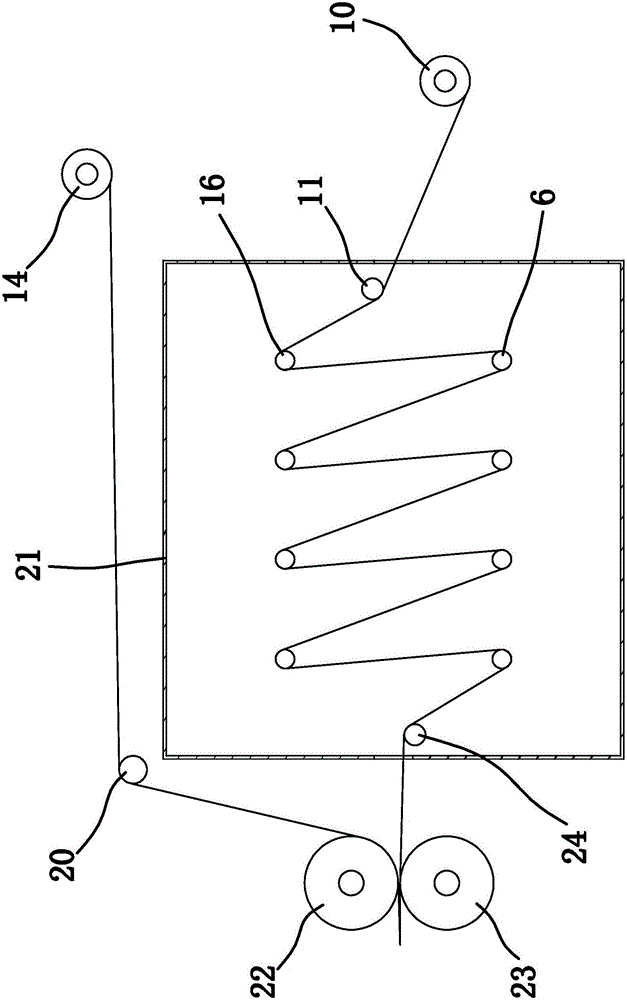

The invention provides spraying and drying equipment for an ultrafine aramid fiber needle-punched filter bag. By adoption of the spraying and drying equipment for the ultrafine aramid fiber needle-punched filter bag, the technical problems that an existing filter bag does not have the characteristics of corrosion resistance, electrostatic resistance, the antibacterial property and the like, can only be used in simple environments, and is poor in functionality are solved. The spraying and drying equipment for the ultrafine aramid fiber needle-punched filter bag comprises a rack, and a spraying device and a drying device are arranged on the rack. The spraying device comprises a isolation box, a delivery pump and a storage box, wherein a cavity is formed inside the isolation box, and the storage box is used for storing a coating solution; the isolation box is fixed to the rack, and an upper spray head and a lower spray head are arranged in the isolation box; the upper spray head is located on the upper portion of the interior of the isolation box, and a first discharging port of the upper spray head faces downwards; the lower spray head is located on the lower portion of the interior of the isolation box, and a second discharging port of the lower spray head faces upwards; and a communicating pipe is connected between a first feeding port of the upper spray head and a second feeding port of the lower spray head, the middle portion of the communicating pipe communicates with the storage box through a delivery pipe, and the delivery pump is arranged in the delivery pipe. The spraying and drying equipment for the ultrafine aramid fiber needle-punched filter bag has the advantages that multiple functions are achieved, and the product quality is good.

Owner:ZHEJIANG YUBANG FILTER MATERIAL TECH CO LTD

Antistatic fiber fabric for embroidery

InactiveCN107558039AAntistatic hasAntistatic avoidanceEmbroidering machines apparatusPolyesterViscose

The invention discloses an antistatic fiber fabric for embroidery. The antistatic fiber fabric for embroidery is prepared from the following components in parts by weight: 10 to 15 parts of algae fibers, 11 to 16 parts of aloe fibers, 5 to 10 parts of silks, 6 to 11 parts of polyurethane fibers, 7 to 12 parts of polyester staple fibers, 0.5 to 0.9 part of modal fibers, 1 to 6 parts of viscose fibers, 0.3 to 0.7 part of milk fibers, and 2 to 6 parts of polylactic acid fibers. By adopting the type, the antistatic fiber fabric for embroidery has the advantages that the antistatic function is realized, and the production of static electricity with skin is avoided.

Owner:SUZHOU YEXIU CRAFTS FACTORY

Anti-static environment-friendly coating fabric and preparing method thereof

ActiveCN105128466AQuick adjustmentStable structureLamination ancillary operationsSynthetic resin layered productsMagnesiumOxide

The invention provides anti-static environment-friendly coating fabric and a preparing method thereof. The technical problems that existing coating fabric does not have flame-retardant, anti-static and wear-resisting properties, can be only applied to simple environment and is poor in functionality, and a preparing method does not exist are solved. The anti-static environment-friendly coating fabric comprises a base cloth layer. A reinforcing layer is fixed to the base cloth layer. The reinforcing layer is prepared from, by mass, 85-100 parts of polyurethane resin, 30-40 parts of organic silicon resin, 10-15 parts of fluorous rubber, 2-4 parts of cross-linking agents, 6-10 parts of anti-static agents, 6-8 parts of magnesium oxide, 25-30 parts of methylbenzene and 3-5 parts of dyestuff. The coating fabric has the advantages of being high in functionality and good in quality.

Owner:苏州格洛博纺织有限公司

Formula for antistatic plastic

The invention discloses a formula for antistatic plastic. The antistatic plastic comprises the following components in percent by weight: 71-83 percent of plastic matrixes, 6-10 percent of antistatic agent, 3-5 percent of thermal stabilizer, 2-4 percent of antioxidant, 1-3 percent of optical stabilizer and 5-7 percent of coupling agent, wherein the antistatic agent, the thermal stabilizer, the antioxidant, the optical stabilizer and the coupling agent are additives. By adopting the formula, polydecamethylene sebacamide plastic can be enabled to have good antistatic performance, high mechanical strength, oxidation resistance, radiation resistance, high thermal stability and the like; and during reaction, due to the coupling agent, the reaction speed is increased, the losses during reaction are decreased and the production cost is reduced.

Owner:潘元平

Blended and interwoven fabric as well as preparation method thereof

InactiveCN105133326AVersatileEasy to adjustSolvent-treatmentVegetal fibresPolytetrafluoroethyleneEngineering

The invention provides a blended and interwoven fabric as well as a preparation method thereof, and solves the technical problems that the conventional interwoven fabric does not have the functions of resisting acids, alkalis, static electricity and high-low temperature, can only be utilized in a simple environment, is low in utilization range and has no preparation methods. The blended and interwoven fabric comprises a base fabric layer, wherein protective layers are arrange on both sides of the base fabric layer; each protective layer comprises the following components in parts by weight: 40-60 parts of a polytetrafluoroethylene concentrated dispersion solution, 2-4 parts of a cross-linking agent, 3-5 parts of an anti-static agent and 0.6-1 part of an anti-oxidant. The blended and interwoven fabric has the advantages of being wide in utilization range and high in quality.

Owner:定远县保尔工贸有限公司

PVC (polyvinyl chloride) decorative board and production method thereof

The invention provides a PVC (polyvinyl chloride) decorative board and a production method of the PVC decorative board. The PVC decorative board and the production method solve the technical problems of too simple component, no antistatic performance, no ageing resistance, single function and the like of the existing decorative board. The PVC decorative board comprises the following components in parts by mass: 70-80 parts of PVC powder, 1-3 parts of paraffin, 0.2-0.4 parts of stearic acid, 3-8 parts of plasticizer, 2-5 parts of flame retardant, 1.2-2.6 parts of heat stabilizer, 5-15 parts of antistatic agent, 0.5-1.2 parts of antioxidant and 20-40 parts of activated ground calcium carbonate. The PVC decorative board has the advantage of high functionality.

Owner:海宁永欣科技咨询有限公司

Antistatic flame-retardant nylon composite material and preparation method thereof

The invention relates to the technical field of nylon composite materials, and particularly provides an antistatic flame-retardant nylon composite material and a preparation method thereof. The antistatic flame-retardant nylon composite material comprises nylon resin, flame retardants and carbon nanotube / graphene staple fibers in a weight ratio of 1:(0.002-0.02):(0.15-0.45).

Owner:深圳前海量子翼纳米碳科技有限公司

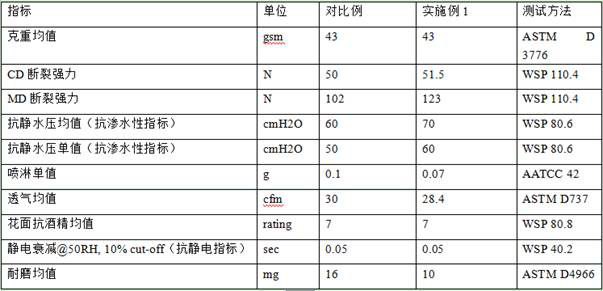

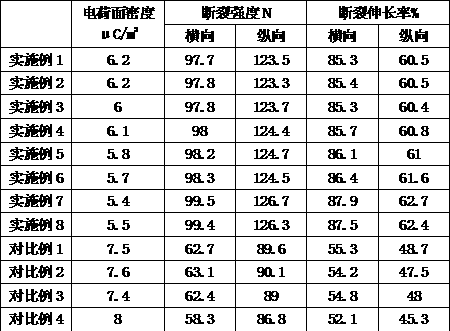

Development of single-sided alcohol-resistant and single-sided anti-static medical SMS

InactiveCN112593347AImprove barrier propertiesImprove water resistanceElectroconductive/antistatic filament manufactureTextile treatment machine arrangementsAlcoholPharmaceutical industry

Disclosed is development of a single-sided alcohol-resistant and single-sided anti-static medical SMS. The development is characterized by comprising the steps of raw material mixing, melt extrusion,drafting, hot rolling, oiling, drying and cooling shaping. According to YY / T 0506.2-2016 standard of the pharmaceutical industry in China and the European BS EN 13795-1: 2019 standard, the water permeability resistance of the single-sided alcohol-resistant and single-sided anti-static medical SMS non-woven fabric meets the requirement of a water column with the single point value of 60 cm; the medical SMS non-woven fabric has higher barrier, higher water seepage resistance and excellent basic physical properties, the pattern surface can keep excellent alcohol resistance, and the smooth surfacehas favorable antistatic property; the single side of the SMS non-woven fabric has antistatic property and the single side of the SMS non-woven fabric has alcohol resistance through direct productioninstead of an after-treatment mode; and productivity improvement and the like can be achieved.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

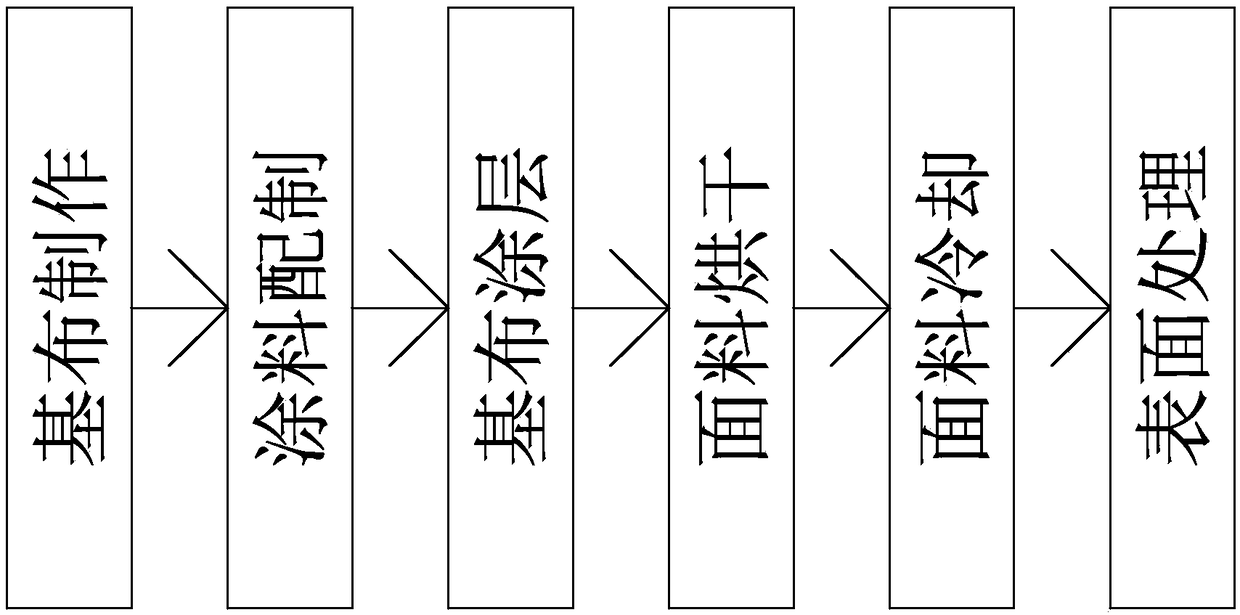

Manufacturing process of multifunctional coating cloth

InactiveCN108330701AManufacturing process advantagesAnti-aging hasLiquid repellent fibresElectrically-conductive paintsPolyesterAntistatic agent

The invention provides a manufacturing process of multifunctional coating cloth, and belongs to the technical field of fabrics. The problem of low production quality in the prior art is solved. The manufacturing process of the multifunctional coating cloth includes the following steps: S1, base cloth preparation: knitting with 75D high-strength polyester filaments; S2, coating preparation: preparing a coating from the following raw materials in parts by mass: 80 parts of a PVC resin powder, 5-7 parts of soybean oil, 6-8 parts of titanium dioxide, 30 parts of calcium carbonate, 2-4 parts of a stabilizer, 2-6 parts of an antiaging agent, and 1-3 parts of an antistatic agent; S3, base cloth coating: putting the coating of the S2 into a coating device of the coating cloth; S4, fabric drying: drying the semi-finished product coating cloth of the S3 through a drying device; S5, fabric cooling: cooling the semi-finished product coating cloth of the S4 through a cooling device; and S6, surfacetreatment: carrying out surface treatment of the product of the S5 by a fluorosilicone finishing agent. The manufacturing process has the advantages of improving the quality of production.

Owner:海宁市华泰针织有限公司

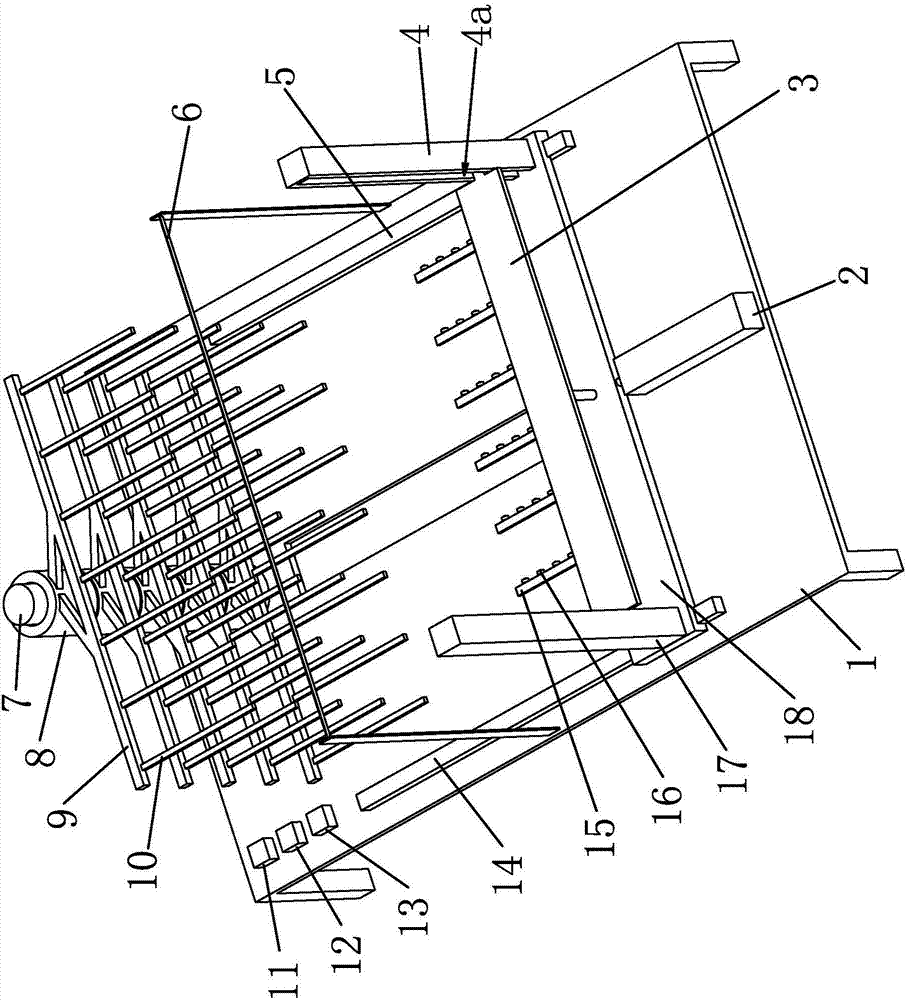

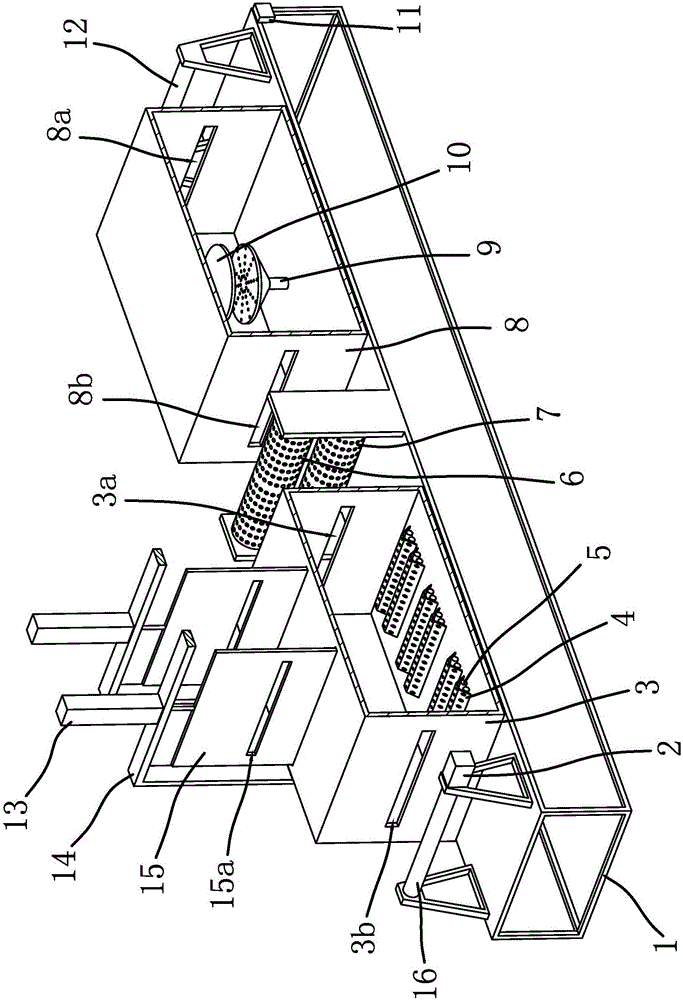

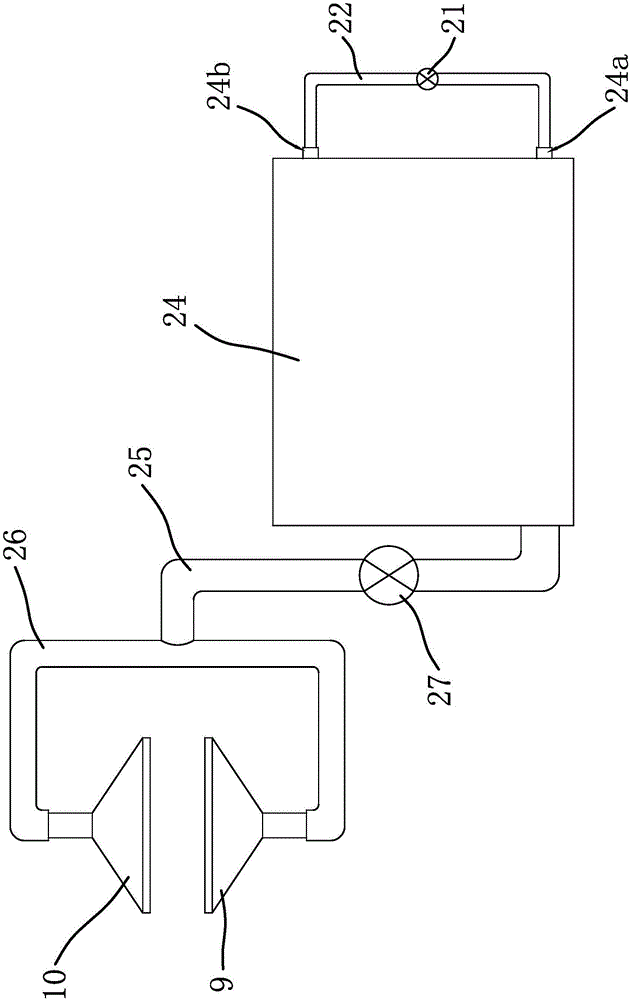

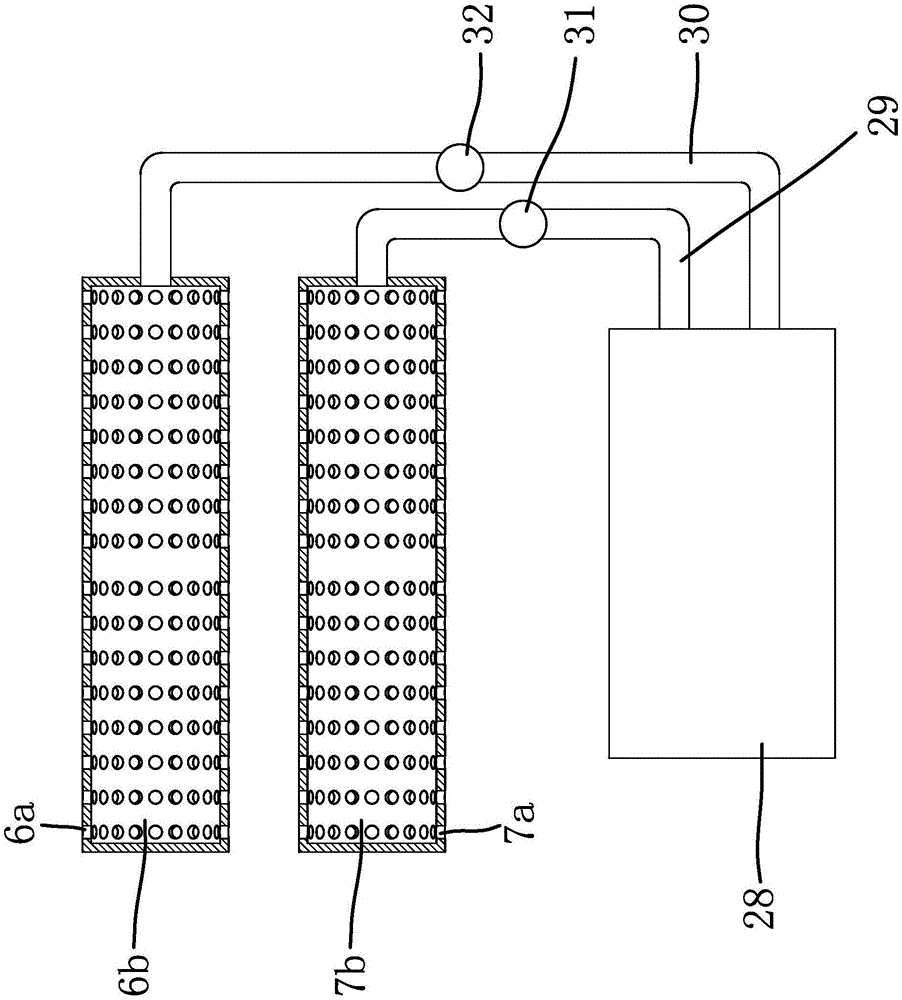

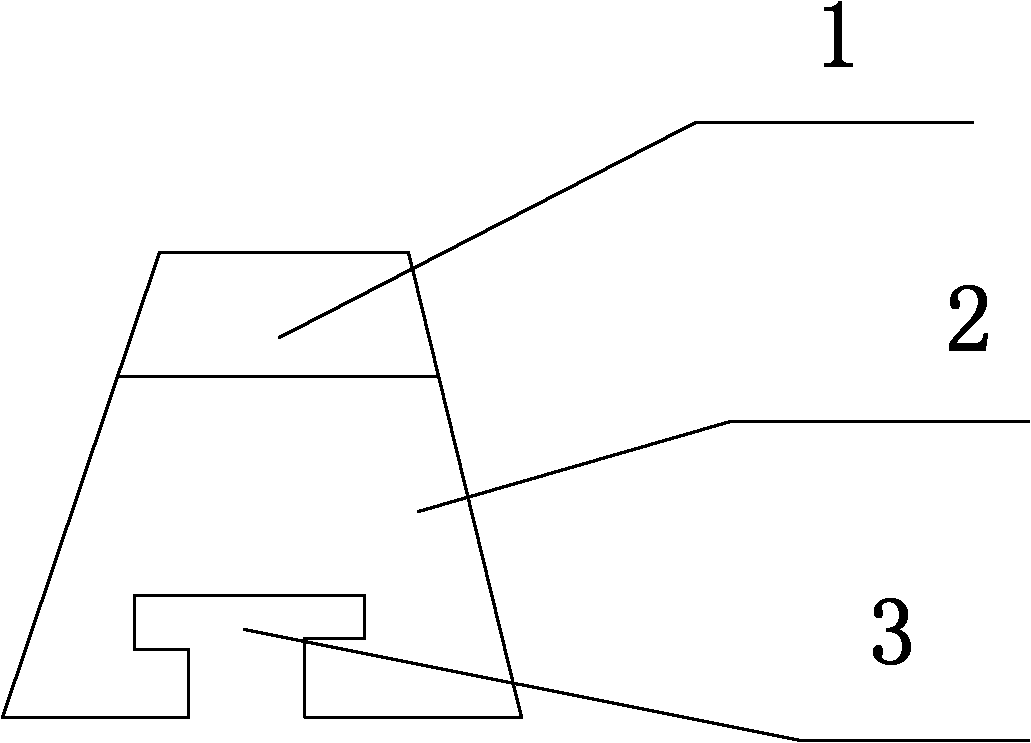

Preparation method of PPS superfine fiber acupuncture filter bag

ActiveCN106345193AAntistatic hasFlame retardantDispersed particle filtrationFiltration separationAcupunctureVolumetric Mass Density

The invention provides a preparation method of a PPS superfine fiber acupuncture filter bag, which solves the technical problems that the existing filter bag does not have the characteristics of flame retardance, antistatic property, high-temperature resistance and the like, only can be applied to a single simple environment and has a single function and a preparation method of the filter bag is unavailable and the like are solved. The preparation method of the PPS superfine fiber acupuncture filter bag comprises the following steps: (a) performing opening, mixing, carding and cross lapping of polyphenylene sulfide and aramid fiber to obtain a base cloth layer with surface density of 170-180g / m<2>; (b) putting the base cloth layer into a common dusting machine and removing the dust and impurities on the surface; (c) weighing the required raw materials; (d) adding the raw materials into a common stirrer to obtain an emulsion; (e) spraying the emulsion on the base cloth layer by a spraying-drying integrated machine, and drying the formed emulsion layer to obtain a protection layer; and (f) sewing the bag body, the bag head and the bag bottom together by a common sewing machine, and processing into the PPS superfine fiber acupuncture filter bag. The preparation method provided by the invention has the advantage of high preparation efficiency.

Owner:ZHEJIANG YUBANG FILTER MATERIAL TECH CO LTD

Multifunctional plastic additive and preparation method thereof

The invention discloses a multifunctional plastic additive and a preparation method thereof. The multifunctional plastic additive comprises 8-13 parts of glass powder, 15-20 parts of dibutyl phthalate, 10-15 parts of synthetic vegetable ester, 8-10 parts of dioctyl phthalate, 10-12 parts of phosphite, 8-10 parts of mercaptoester, 5-8 parts of mica powder, 4-7 parts of carbon powder, 2-4 parts of trioctyl ester, 10-15 parts of benzotriazole, 20-25 parts of salicylate, 4-10 parts of aluminum hydroxide, 2-5 parts of an inorganic nano material, 12-15 parts of ethoxylated alkyl polyamine, 15-20 parts of alkyl trimethyl quaternary ammonium, 5-10 parts of an antistatic agent, 1-3 parts of a silane coupling agent, 2-6 parts of methyl silicone oil, 0.1-0.2 part of an antibacterial agent and 0.5-1 part of a toughening agent. The multifunctional plastic additive has oxidation resistance, an antistatic property, sterilization and plasticity convenience, the strength can be improved, and furthermore, a function of facilitating storage is further fulfilled.

Owner:广州梵泰新材料科技有限公司

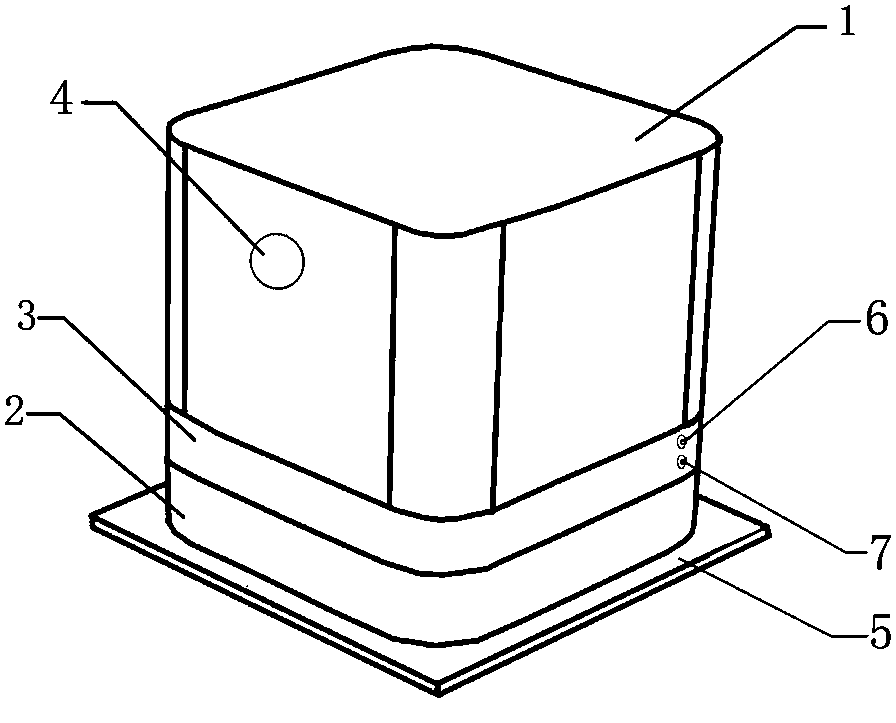

A kind of preparation method of pps superfine fiber acupuncture filter bag

ActiveCN106345193BAntistatic hasFlame retardantDispersed particle filtrationFiltration separationFiberAcrylic resin

The invention provides a PPS ultrafine fiber acupuncture filter bag and a manufacturing method thereof. The PPS ultrafine fiber acupuncture filter bag and the manufacturing method solve the technical problems that existing filter bags do not have the characteristics such as flame retardance, static resistance and high temperature resistance, can only be used for simplex and simple environments and are simplex in use, and no preparation method for preparing the existing filter bags exists. The PPS ultrafine fiber acupuncture filter bag comprises a bag body, a bag head and a bag bottom. One end of the bag body is fixed to the bag head, and the other end of the bag body is fixed to the bag bottom. The bag body comprises a base cloth layer and protection layers. The protection layers are fixed to the two side faces of the base cloth layer respectively. Each protection layer is prepared from, by weight, 70-80 parts of polytetrafluoroethylene concentrated dispersion liquid, 1-2 parts of coupling agents, 10-15 parts of epoxy phenolic resin, 1-2 parts of thermosetting acrylic resin, 0.5-0.8 part of polymethylphenyl siloxane fluid, 3-6 parts of magnesium oxide, 3-6 parts of zinc oxide, 1-2 parts of antistatic agents and 30-60 parts of deionized water. The manufacturing method of the PPS ultrafine fiber acupuncture filter bag is provided. The PPS ultrafine fiber acupuncture filter bag and the manufacturing method have the advantages of being high in practicability and manufacturing efficiency.

Owner:ZHEJIANG YUBANG FILTER MATERIAL TECH CO LTD

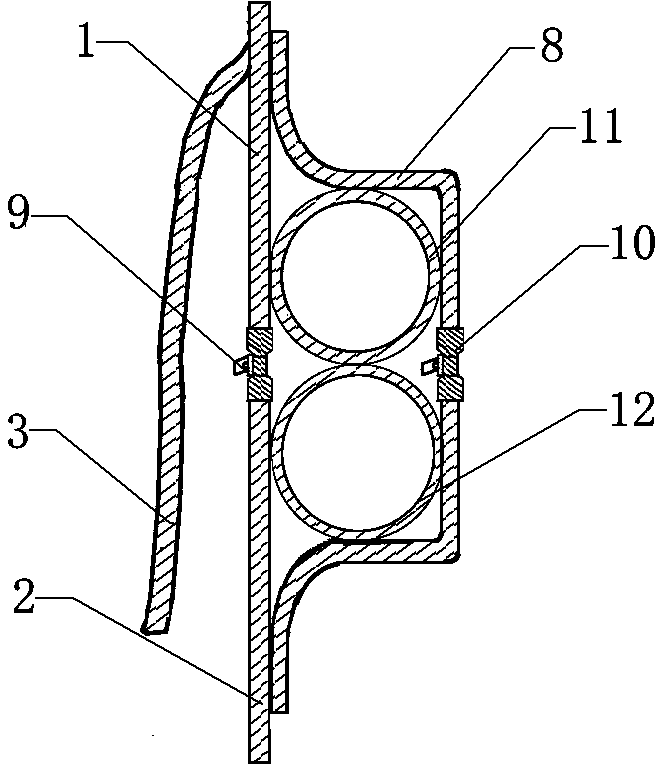

Preparation method of aramid superfine fiber needled filter bag

ActiveCN106390623AAntistatic hasCorrosion resistanceDispersed particle filtrationSpraying apparatusGlass fiberEmulsion

The invention provides a preparation method of an aramid superfine fiber needled filter bag. By using the preparation method of the aramid superfine fiber needled filter bag, the technical problems that an existing filter bag has no characteristics of corrosion resistance, antistatic performance, antibacterial performance and the like, can be only used in a simple environment, and is poor in functionality, further, a preparation method for preparing the filter bag does not exist, and the like are solved. The preparation method of the aramid superfine fiber needled filter bag comprises the following steps of a, making an aramid fiber, a glass fiber and polyphenyl thioether into a basic fabric layer of which the surface density is 180g / m<2> to 185g / m<2> through opening, mixing, carding and cross lapping; b, introducing the basic fabric layer into an ordinary singeing and calendering machine to carry out singeing and calendering treatment; c, introducing the basic fabric layer into an ordinary dust removing machine to remove an ash layer and an impurity on a surface; d, weighing to take needed raw materials; f, adding the raw materials into an ordinary agitating machine so as to make an emulsion; g, spray-coating the emulsion on the basic fabric layer through a spray-coating and oven-drying device; h, sewing up a bag body, a bag head and a bag bottom together through an ordinary sewing machine. The preparation method of the aramid superfine fiber needled filter bag has the advantage that the product quality is good.

Owner:ZHEJIANG YUBANG FILTER MATERIAL TECH CO LTD

Flame retardant antistatic polypropylene composition and foamed bead prepared therefrom

ActiveCN107325393AMeet the requirements of environmental protection and safetyHigh flame retardant efficiencyPolymer scienceEthylene Homopolymers

The invention provides a flame retardant polypropylene composition, a flame retardant antistatic polypropylene composition, and a flame retardant (antistatic) polypropylene foamed bead, and a preparation method and applications thereof. The flame retardant antistatic polypropylene foamed bead is prepared from the flame retardant antistatic polypropylene composition, which comprises polypropylene basic resin with a high melt strength, the flame retardant antistatic composition, a cellular nucleating agent, and optionally selected auxiliary agents such as antioxidant, by a foaming technology; and preferably, the polypropylene basic resin comprises a propylene homopolymer component and an ethylene-1-butene copolymer component. A moulded body prepared from the flame retardant antistatic polypropylene foamed bead has a good flame retardant and antistatic performance, excellent mechanical properties, and a wide application range.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sealed type seal sleeve for air bag

ActiveCN102991871BPuncture resistance hasTear resistance hasSynthetic resin layered productsPackagingAir tightnessCompositermes

Owner:中国人民解放军32181部队

A kind of preparation method of infant clothing fabric

ActiveCN113047051BHas antibacterial and deodorizing functionsHigh strengthWeft knittingWarp knittingCelluloseCotton fibre

The invention discloses a preparation method for infant clothing fabrics, which comprises adding β-N-acetylglucosaminidase into distilled water, stirring and dissolving to form a 2.2-2.6% enzyme solution, and adding dopamine and chitosan into the enzyme solution , to obtain solution I; soak cotton fiber and soybean fiber in solution I, heat to 65-70°C and vibrate and stir for 3-4 hours, then take it out and dry it naturally, wash it with distilled water and dry it to obtain the modified treatment The final cotton fiber and soybean fiber; fully mixed sea squirt cellulose, castor oil and sodium alginate and then ground them, and sieved to obtain a powder, which was melt-spun, drawn, and shaped to obtain fiber I; the fiber I was soaked in the solution I, heated to 65-70°C, shaken and stirred for 3-4 hours, then fished out and dried naturally, washed with distilled water and dried to obtain the modified fiber I; the modified cotton fiber and soybean fiber and The modified fiber I is blended to obtain a fabric, and then the fabric is subjected to low-temperature plasma treatment to obtain the infant clothing fabric.

Owner:东莞市康顺纺织品有限公司

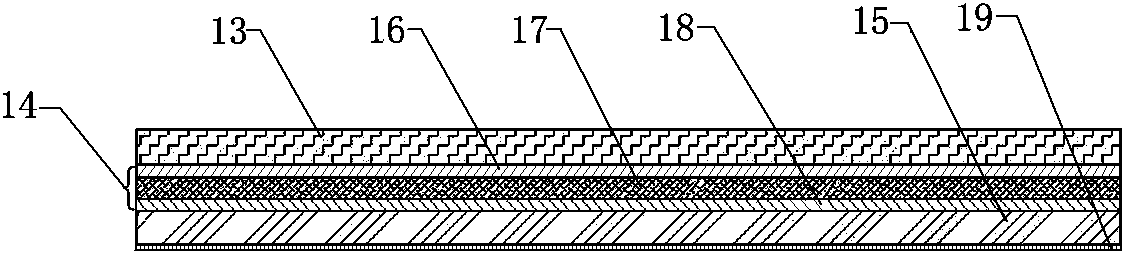

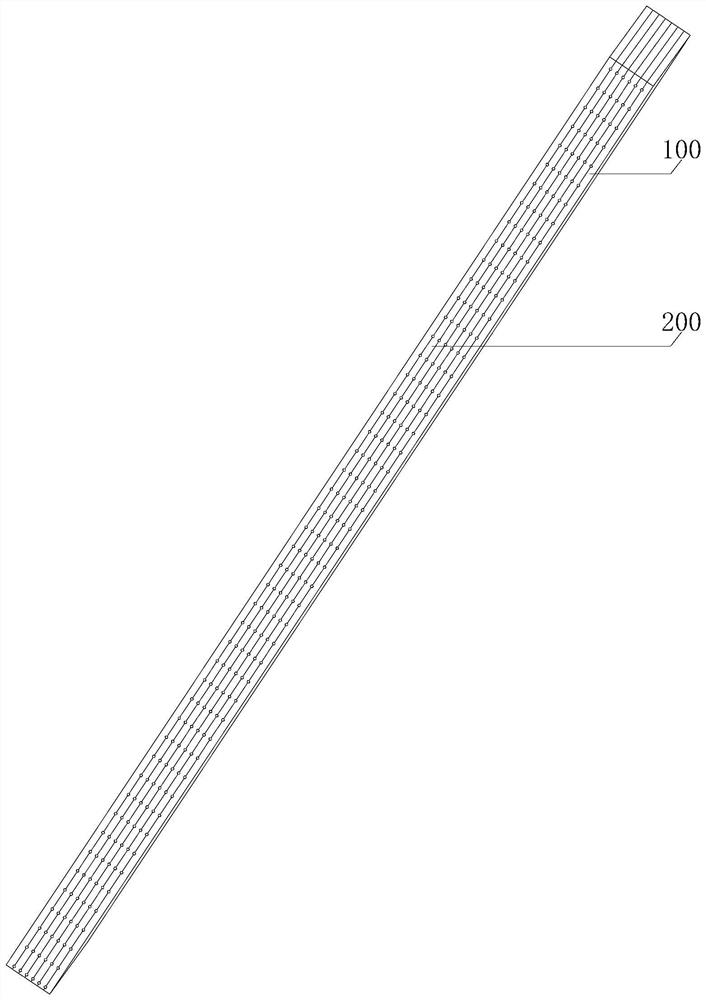

Special strip for ultrahigh-voltage cable and production method of special strip

PendingCN114193886AHigh strengthHigh mechanical modulusLamination ancillary operationsSynthetic resin layered productsUltra high voltageElectric machine

The invention provides a special strip for an ultrahigh-voltage cable and a production method of the special strip, and belongs to the technical field of cables. The special strip for the ultrahigh-voltage cable comprises a basic assembly and a reinforcing assembly. The basic assembly comprises a nylon layer and a rubber layer, the rubber layer is fixed on the outer wall of the nylon layer, and the reinforcing assembly comprises a flame-retardant layer, a tensile layer, an insulating layer, an antistatic layer, a wear-resistant layer and reinforcing ribs. During use, the insulating layer is attached to the wear-resistant layer to synthesize a special strip, an output shaft of a motor on the winding device is controlled to rotate reversely, the synthesized special strip penetrates through the stamping device, and layers on the special strip are tightly pressed together under the combined action of an upper die and a lower die of the stamping device. The special strip has the advantages of being flame-retardant, tensile, insulating, antistatic, wear-resistant, high in bearing capacity, high in reversible deformation, rich in elasticity and the like, and the applicability of the special strip is improved.

Owner:无锡市恒龙电缆材料有限公司

Safety protector for electric power failure overhauling

InactiveCN109045510AEasy to carryImprove mechanical propertiesSafety beltsWork tools storageFiberEngineering

The invention provides a safety protector for electric power failure overhauling, and belongs to the technical field of electric power overhauling tools. The safety protector comprises a safety belt body and a tool bag, and the safety belt body comprises a waist belt and two back shoulder belts arranged on the waist belt. One ends of the back shoulder belts are fixedly arranged on one side of thewaist belt, and the other ends of the back shoulder belts bypass the shoulders of a human body to be connected to the other side of the waist belt in an intersecting mode. A self-locking hook connected with a hanging rope is arranged on the waist belt, a pull ring is arranged at one end of the waist belt, and a buckle is arranged at the other end of the waist belt. The tool bag is arranged on thewaist belt, a plurality of sealing belts are arranged in the tool bag, and the sealing belts divide the tool bag into a plurality of segments. Through the safety protector, the problem that high-altitude working tools are inconvenient to carry is solved. The safety belt body and the tool bag are made from modified complex fibers and olefinoate series electrical fibers in a hybrid mode, and the safety protector has the excellent mechanical property and the antistatic property and provides a safety guarantee for high-altitude working.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

A kind of antistatic environment-friendly coated fabric and preparation method thereof

ActiveCN105128466BAntistatic hasStable structureLamination ancillary operationsSynthetic resin layered productsEngineeringSilicon

Owner:苏州格洛博纺织有限公司

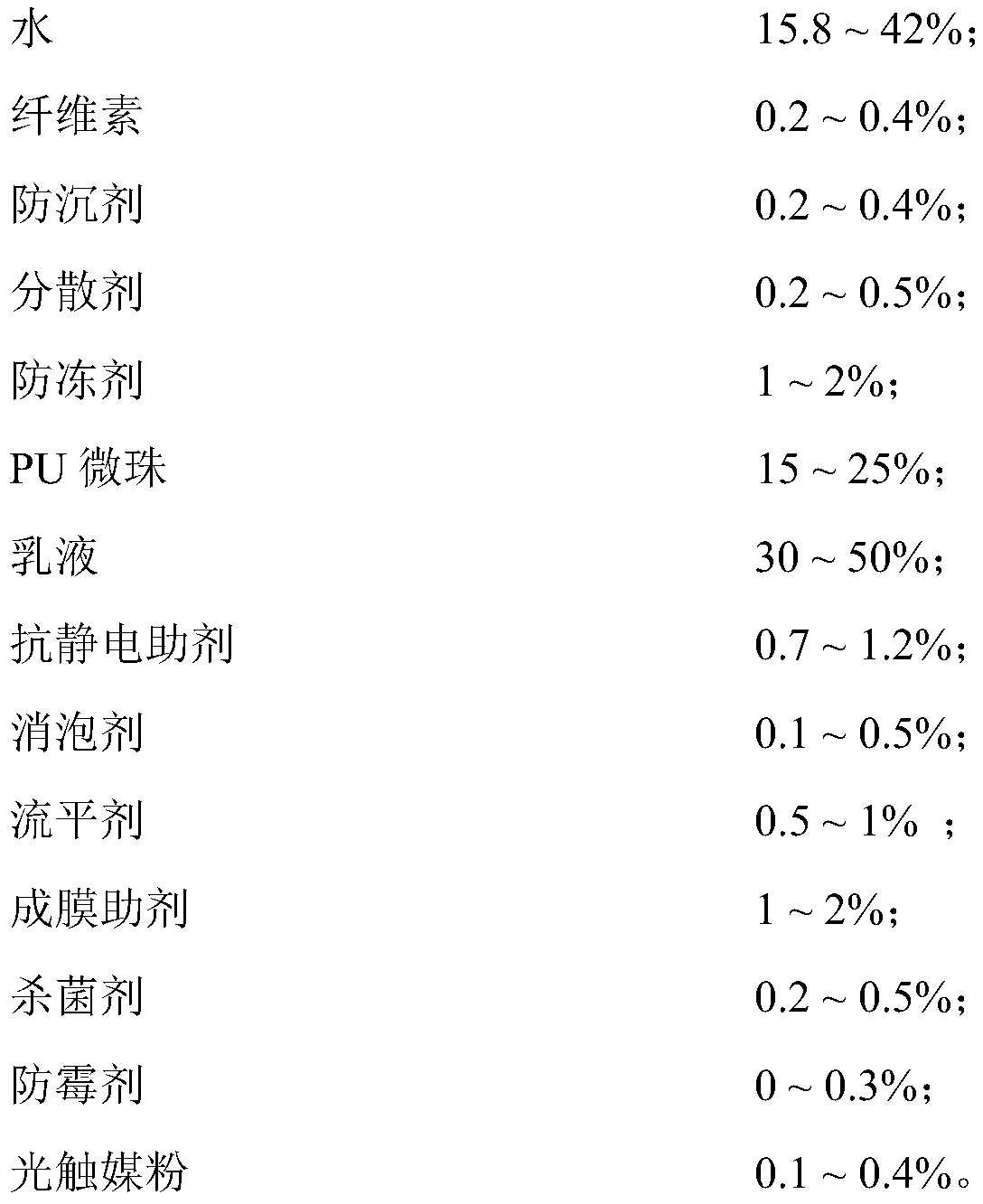

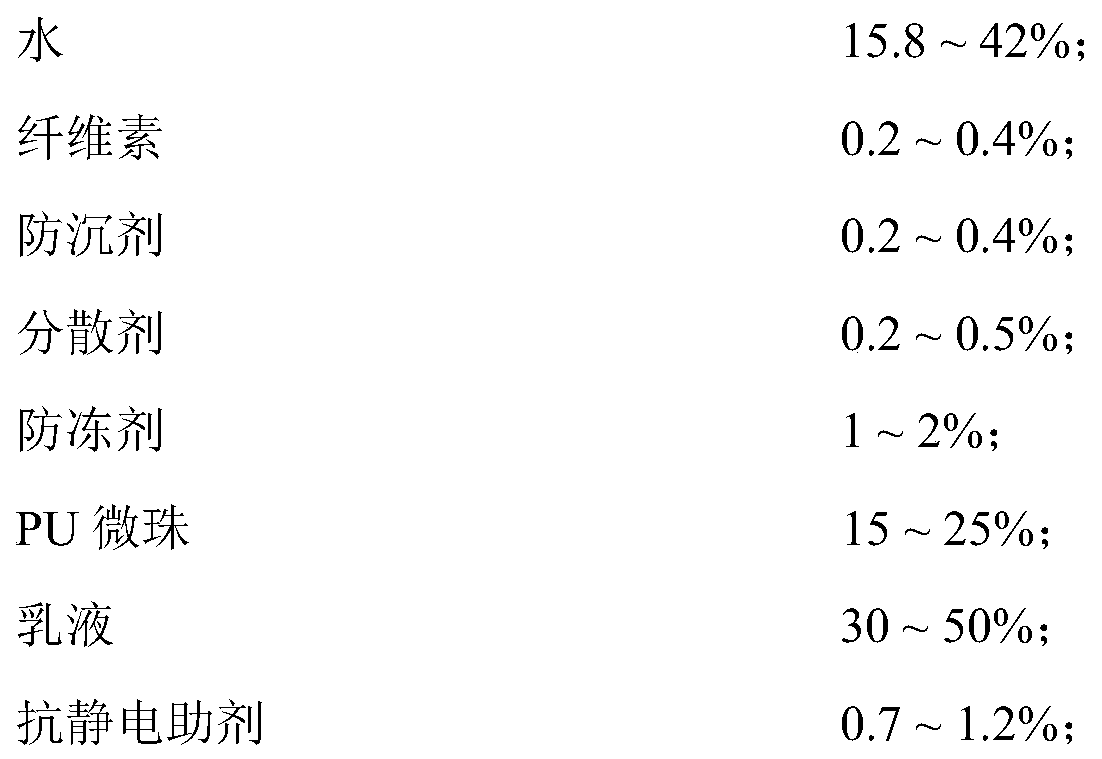

Water-based antistatic velour-handfeeling artistic coating

InactiveCN110655865AAntistatic hasWith net aldehyde sterilizationAntifouling/underwater paintsPaints with biocidesPhotocatalysisEmulsion

The invention provides a water-based antistatic velour-handfeeling artistic coating which is characterized by being prepared from the following raw materials: water, cellulose, an anti-settling agent,a dispersing agent, an anti-freezing agent, PU microspheres, an emulsion, an antistatic aid, an antifoaming agent, a leveling agent, a coalescing agent, a bactericide, a mildew preventive and photocatalyst powder. According to the water-based antistatic velour-handfeeling artistic coating and the preparation method thereof, composite colors and elastic velvet hand feeling on wall surfaces can beachieved through simple spraying of the water-based antistatic velour-handfeeling artistic coating, formed coating layers are attached to the wall like thin velour, wall surface decoration functionsare achieved, and formaldehyde removal function, sterilization, odor removal, static resistance, dust prevention functions and the like are achieved. The wall surfaces coated with the water-based antistatic velour-handfeeling artistic coating have composite colors and elastic velvet hand feeling.

Owner:鳄鱼制漆(上海)有限公司

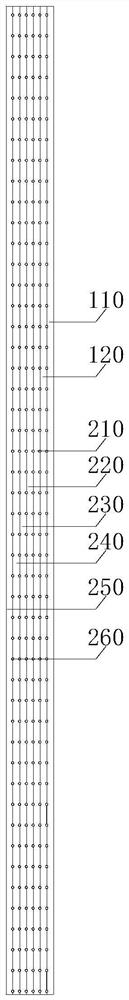

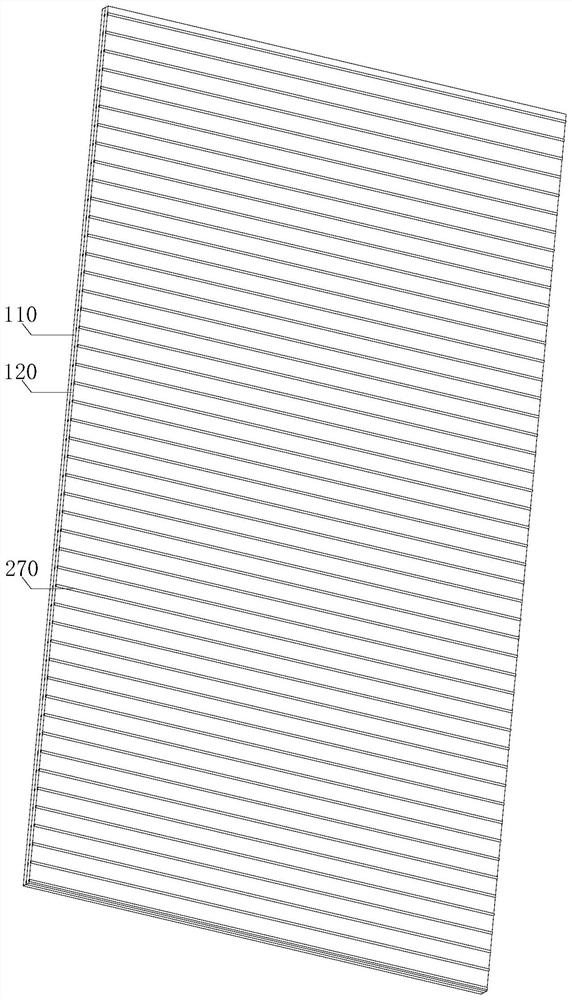

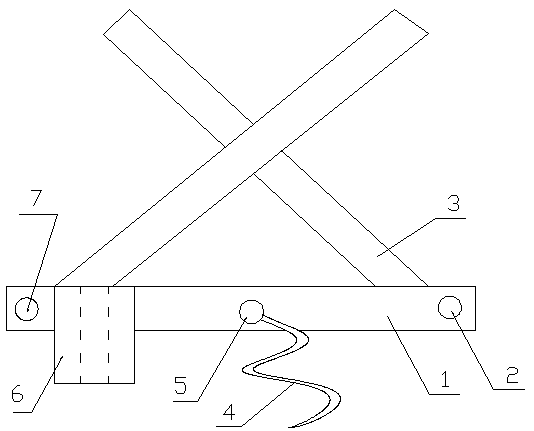

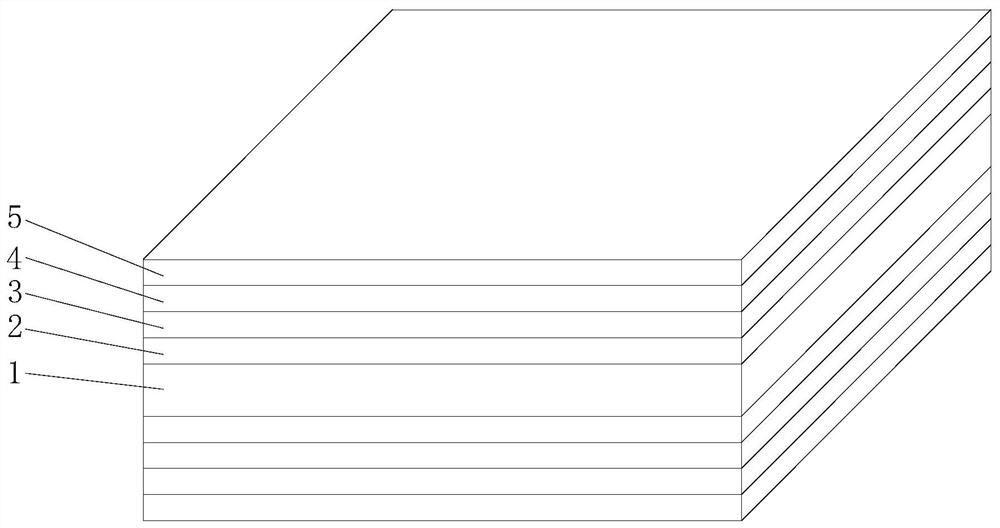

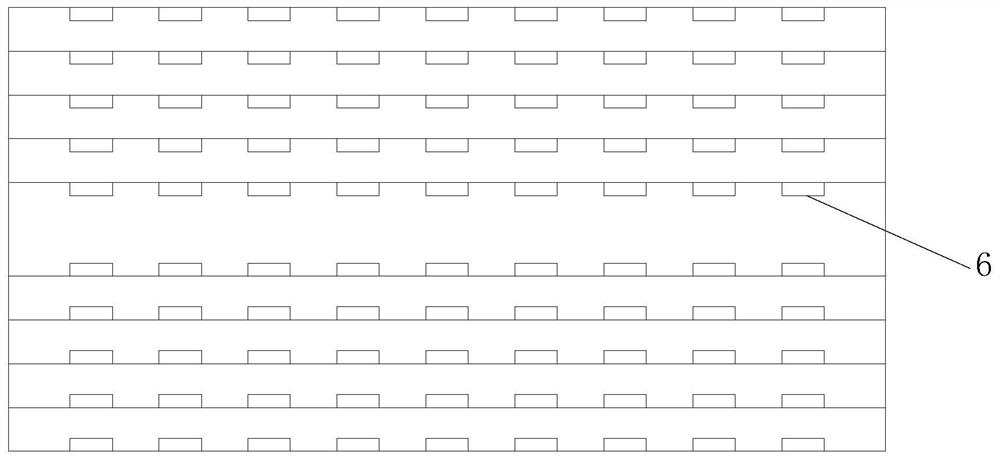

Non-woven fabrics and winding machine for producing same

ActiveCN112645100AAntistatic hasUV protection hasArticle deliveryWebs handlingTextile technologyWinding machine

The invention discloses non-woven fabrics and a winding machine for producing the same, and relates to the technical field of textile technologies. The non-woven fabrics comprises a base material layer, an antistatic layer, an ultraviolet-proof layer, a flame-retardant layer and a wear-resistant layer, wherein the antistatic layer, the ultraviolet-proof layer, the flame-retardant layer and the wear-resistant layer are arranged at two sides of the base material layer in sequence from inside to outside. According to the non-woven fabrics and the winding machine, through the arrangement of the antistatic layer, the ultraviolet-proof layer, the flame-retardant layer and the wear-resistant layer, the non-woven fabrics have antistatic, ultraviolet-proof, flame-retardant and wear-resistant functions and is wider in application field, the structural strength of the whole non-woven fabrics is greatly improved through mutual bonding of the multiple polypropylene resin layers; through the arrangement of grooves, the layers can be connected more tightly; and through the arrangement of a cutting mechanism and a film winding mechanism, the winding machine can achieve the automatic film winding operation, and compared with a conventional packaging winding mechanism, the operation is simpler and more convenient.

Owner:肇庆市盛宝丽纺织有限公司

Buffer strip for blanking port of belt conveyor

InactiveCN102009834APlay a protective effectAvoid wear and tearConveyor partsStructural engineeringBelt conveyor

The invention relates to a buffer strip for a blanking port of a belt conveyor, comprising a metal special-shaped material, a plate body and a buffer body, wherein the plate body is fixedly arranged on the upper surface of the buffer body; and the metal special-shaped material is fixedly arranged on the lower surface of the buffer body. Therefore, the rigidity of the buffer strip is improved, the butter strip can bear greater impact during the facility operation, and the full support is provided for a belt, thus, the impact resistance of the belt is greatly improved, the service life of the belt is prolonged, and the plate body can protect the buffer body so as to avoid the abrasion of the buffer body.

Owner:江苏金波新材料科技有限公司

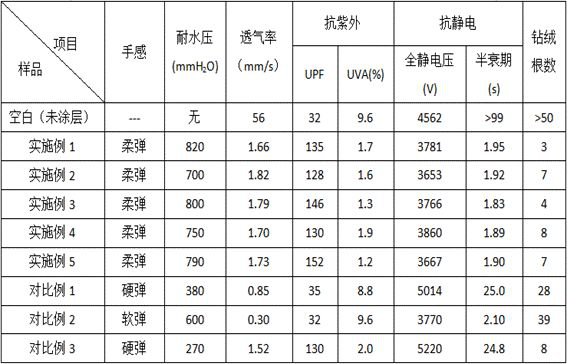

Textile water-based polyurethane coating glue and fabric treatment method

ActiveCN109610183BGuaranteed antistatic effectGuaranteed breathableTextiles and paperPolymer sciencePolyurethane adhesive

The invention relates to a waterborne polyurethane coating adhesive for a textile and a fabric treatment method. The waterborne polyurethane coating adhesive is prepared by compounding 60-70 parts byweight of waterborne polyurethane emulsion, 2.0-4.0 parts by weight of organic silicon modified elastic microspheres, 2.0-4.0 parts by weight of an anti-static agent, 0.5-1.0 part by weight of an ultraviolet absorbent, 0.2-0.3 part by weight of a waterborne de-foaming agent, 2.0-4.0 parts by weight of an association type waterborne polyurethane thickener and 30-40 parts by weight of deionized water. The fabric achieves the functions of air permeability, water pressure resistance, ultraviolet resistance, static electricity resistance and downproofness after being coated with the waterproof, glossy and waterborne polyurethane adhesive.

Owner:LIAONING FIXED STAR FINE CHEM

A preparation method of a flame-retardant antistatic super comfortable safety protection fabric

InactiveCN105369454BAntistatic hasAntistatic modified polyester/flame retardant hasProtective fabricsYarnPolyesterFiber

The invention discloses a manufacturing method for a flame-retardant antistatic super-comfortable fabric used for safety protection. The flame-retardant antistatic super-comfortable fabric used for safety protection uses yarns formed by blending ultrahigh molecular weight polyethylene / antistatic modified polyester / flame-retardant viscose staple fibers as the raw material, and is manufactured by a weaving production method. The method specifically comprises: double strands of warps and wefts plying to form plied yarns by using the ultrahigh molecular weight polyethylene / antistatic modified polyester / flame-retardant viscose staple fiber blended yarns, through sectional beaming, making into a warp beam, and producing the flame-retardant antistatic super-comfortable fabric used for safety protection on a high-end rapier loom, through off-loom finishing, and through special finishing, a finished product is obtained. The method is rational in raw material matching, short in process flow, high in production efficiency, relatively low in production cost, and stable in product quality, and the process is easy to implement.

Owner:NANTONG YUEYE TEXTILE CO LTD

A flame-retardant antistatic super strong yarn and its production method

The invention discloses flame-retardant antistatic super-strong yarn and a production method thereof. According to the technical scheme, the flame-retardant antistatic super-strong yarn comprises 10-20 parts of ultra-high molecular weight polyethylene short fibers, 40-60 parts of antistatic modified polyester fibers and 30-50 parts of flame-retardant viscose fibers. The production method of the yarn comprises the steps of getting each of the ultra-high molecular weight polyethylene short fibers and the antistatic modified polyester fibers to be subjected to the pretreatment, picking opening, cotton carding and pre-doubling procedure in sequence, and then leaving the fibers for standby application; getting the flame-retardant viscose fibers to be subjected to the picking opening, cotton cardng and pre-doubling procedure in sequence; getting the ultra-high molecular weight polyethylene short fibers, the antistatic modified polyester fibers and the flame-retardant viscose fibers which are pre-doubled to be subjected to the drawing, roving, spinning and spooling procedure in sequence, and obtaining the flame-retardant antistatic super-strong yarn. According to the flame-retardant antistatic super-strong yarn and the production method thereof, the characteristics that positive ion modified antistatic dacron is good in both mechanical property and physical property, excellent in quality and reasonable in price and good moisture absorption performance and easy-dyeing performance of flame-retardant viscose are combined, and advantages of the positive ion modified antistatic dacron and the flame-retardant viscose in performance, price, application and other aspects are exploited.

Owner:IANGSU COLLEGE OF ENG & TECH

Flame-retardant antistatic polypropylene composition and expanded beads prepared therefrom

The invention mainly provides a flame retardant polypropylene composition, a flame retardant antistatic polypropylene composition, a flame retardant (antistatic) polypropylene foamed bead, and a preparation method and application thereof. Wherein, the flame retardant and antistatic polypropylene foam beads are made of flame retardant materials containing high melt strength polypropylene base resin, flame retardant and antistatic composition, cell nucleating agent and optional antioxidant and other auxiliary agents. The antistatic polypropylene composition is prepared through a foaming process, and the polypropylene base resin includes a propylene homopolymer component and an ethylene-1-butene copolymer component. The molded body prepared from the flame-retardant and antistatic polypropylene foamed beads has good flame-retardant and antistatic properties, excellent mechanical properties, and is widely used.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com