Textile water-based polyurethane coating glue and fabric treatment method

A technology of water-based polyurethane and textiles, applied in the field of nylon fabrics, to achieve the effects of strong hydrophobicity, large molar extinction number, and good water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

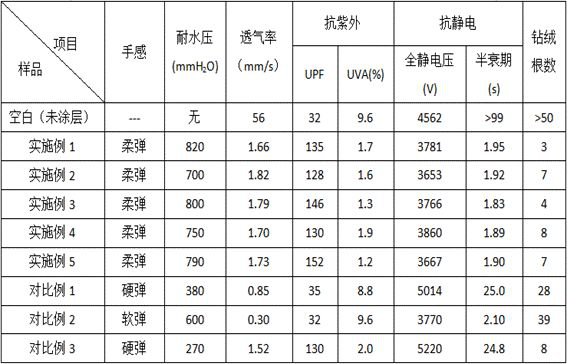

Examples

Embodiment 1

[0056] (1) Mix 30 parts of deionized water and 2.0 parts of silicone modified elastic microspheres and stir evenly;

[0057] (2) Add 70 parts of water-based polyurethane emulsion, 2.0 parts of antistatic agent, 0.5 parts of ultraviolet absorber, and 0.2 parts of water-based defoamer, and stir evenly;

[0058] (3) Add 2.0 parts of associative water-based polyurethane thickener, stir evenly, and filter to obtain water-based polyurethane coating glue; the solid content is 28.87%, and the viscosity is 1730mPa·s;

[0059] (4) Waterproof the 20D / 380T nylon fabric base fabric: soak and roll with C6 waterproof agent (10g / L), dry at 165-170°C for 1 minute;

[0060] (5) Calendering treatment: pressure 10MPa, 80°C;

[0061] (6) Coating treatment: use the water-based polyurethane coating glue obtained in the above step (3) to dry-coat the base cloth obtained in the above step (5), with a knife thickness of 1.5mm, and place it in an oven at 150-165°C Dry for 1 minute, dry weight gain 7.0...

Embodiment 2

[0064] (1) Mix 33 parts of deionized water and 4.0 parts of silicone modified elastic microspheres and stir evenly;

[0065] (2) Add 67 parts of water-based polyurethane emulsion, 3.0 parts of antistatic agent, 0.75 parts of ultraviolet absorber, and 0.3 parts of water-based defoamer, and stir evenly;

[0066] (3) Add 2.5 parts of associative water-based polyurethane thickener, stir evenly, and filter to obtain water-based polyurethane coating glue; solid content 28.77%, viscosity 1680mPa·s;

[0067] (4) Waterproof the 20D / 380T nylon fabric base fabric: soak and roll with C6 waterproof agent (10g / L), dry at 165-170°C for 1 minute;

[0068] (5) Calendering treatment: pressure 10MPa, 100°C;

[0069] (6) Coating treatment: use the water-based polyurethane coating glue obtained in the above step (3) to dry-coat the base cloth obtained in the above step (5), with a knife thickness of 0.5mm, and place it in an oven at 150-165°C Dry for 1 minute, dry weight gain 5.0g / m 2 .

[007...

Embodiment 3

[0072] (1) Mix 35 parts of deionized water and 3.0 parts of silicone modified elastic microspheres and stir evenly;

[0073] (2) Add 65 parts of water-based polyurethane emulsion, 3.0 parts of antistatic agent, 1.0 part of ultraviolet absorber, and 0.2 parts of water-based defoamer, and stir evenly;

[0074] (3) Add 3.0 parts of associative water-based polyurethane thickener, stir evenly, and filter to obtain water-based polyurethane coating glue; the solid content is 27.16%, and the viscosity is 1750mPa·s;

[0075] (4) Waterproof the 20D / 380T nylon fabric base fabric: soak and roll with C6 waterproof agent (10g / L), dry at 165-170°C for 1 minute;

[0076] (5) Calendering treatment: pressure 10MPa, 90°C;

[0077] (6) Coating treatment: use the water-based polyurethane coating glue obtained in the above step (3) to dry-coat the base cloth obtained in the above step (5), with a knife thickness of 1.0mm, and place it in an oven at 150-165°C Dry for 1 minute, dry weight gain 6.0g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com