Development of single-sided alcohol-resistant and single-sided anti-static medical SMS

An anti-alcohol and anti-static technology, which is used in the manufacture of conductive/anti-static filaments, the processing of textile materials, and the configuration of equipment for processing textile materials. Barrier, high impermeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

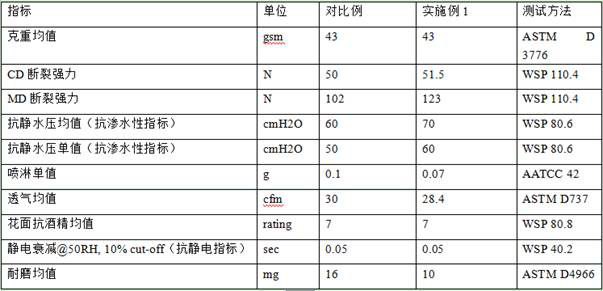

Examples

Embodiment 1

[0034] The development of a single-side anti-alcohol and single-side antistatic medical SMS includes the steps of: mixing of raw materials, melt extrusion, drawing, hot rolling, oiling, drying, cooling and setting.

[0035] The mixing of the raw materials, the raw materials are uniformly mixed according to a certain ratio through a screw extruder to obtain a raw material mixture;

[0036] The raw materials include PP spunbond material, PP meltblown material, fluoride, blue masterbatch, antistatic agent, and the mass ratio is 72.1:20:5.5:2:0.4;

[0037] The blue masterbatch is a spinnable blue pigment.

[0038] The PP spunbonded material has an MFR range of 33-39g / 10min;

[0039] The PP meltblown material has an MFR range of 1100-1800g / 10min;

[0040] The fluoride is a fluorine acrylate copolymer;

[0041] The antistatic agent is potassium phosphate.

[0042] In the melt extrusion, after melting the raw material mixture, the spunbonded material is quantitatively extruded th...

Embodiment 2

[0054] The development of a single-side anti-alcohol and single-side antistatic medical SMS includes the steps of: mixing of raw materials, melt extrusion, drawing, hot rolling, oiling, drying, cooling and setting.

[0055] The mixing of the raw materials, the raw materials are uniformly mixed according to a certain ratio through a screw extruder to obtain a raw material mixture;

[0056] The raw materials include PP spunbond material, PP meltblown material, fluoride, blue masterbatch, antistatic agent, and the mass ratio is 71.6:22:4.0:2:0.4;

[0057] The blue masterbatch is a spinnable blue pigment.

[0058] The PP spunbonded material has an MFR range of 33-39g / 10min;

[0059] The PP meltblown material has an MFR range of 1100-1800g / 10min;

[0060] The fluoride is a fluorine acrylate copolymer;

[0061] The antistatic agent is potassium phosphate.

[0062] In the melt extrusion, after melting the raw material mixture, the spunbonded material is quantitatively extruded th...

Embodiment 3

[0074] The development of a single-side anti-alcohol and single-side antistatic medical SMS includes the steps of: mixing of raw materials, melt extrusion, drawing, hot rolling, oiling, drying, cooling and setting.

[0075] The mixing of the raw materials, the raw materials are uniformly mixed according to a certain ratio through a screw extruder to obtain a raw material mixture;

[0076] The raw materials include PP spunbond material, PP meltblown material, fluoride, blue masterbatch, antistatic agent, and the mass ratio is 72.45:20:5.0:2:0.55;

[0077] The blue masterbatch is a spinnable blue pigment.

[0078] The PP spunbonded material has an MFR range of 33-39g / 10min;

[0079] The PP meltblown material has an MFR range of 1100-1800g / 10min;

[0080] The fluoride is a fluorine acrylate copolymer;

[0081] The antistatic agent is potassium phosphate.

[0082] In the melt extrusion, after melting the raw material mixture, the spunbonded material is quantitatively extruded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com