Subgrade rolling monitoring system and calculation method of number of subgrade rolling times based on RGB algorithm

A monitoring system and calculation method technology, applied in the field of acquisition sensors, can solve problems such as leakage of pressure, poor objectivity, uneven compaction, etc., and achieve the effects of improving efficiency, ensuring construction quality, and avoiding pressure leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

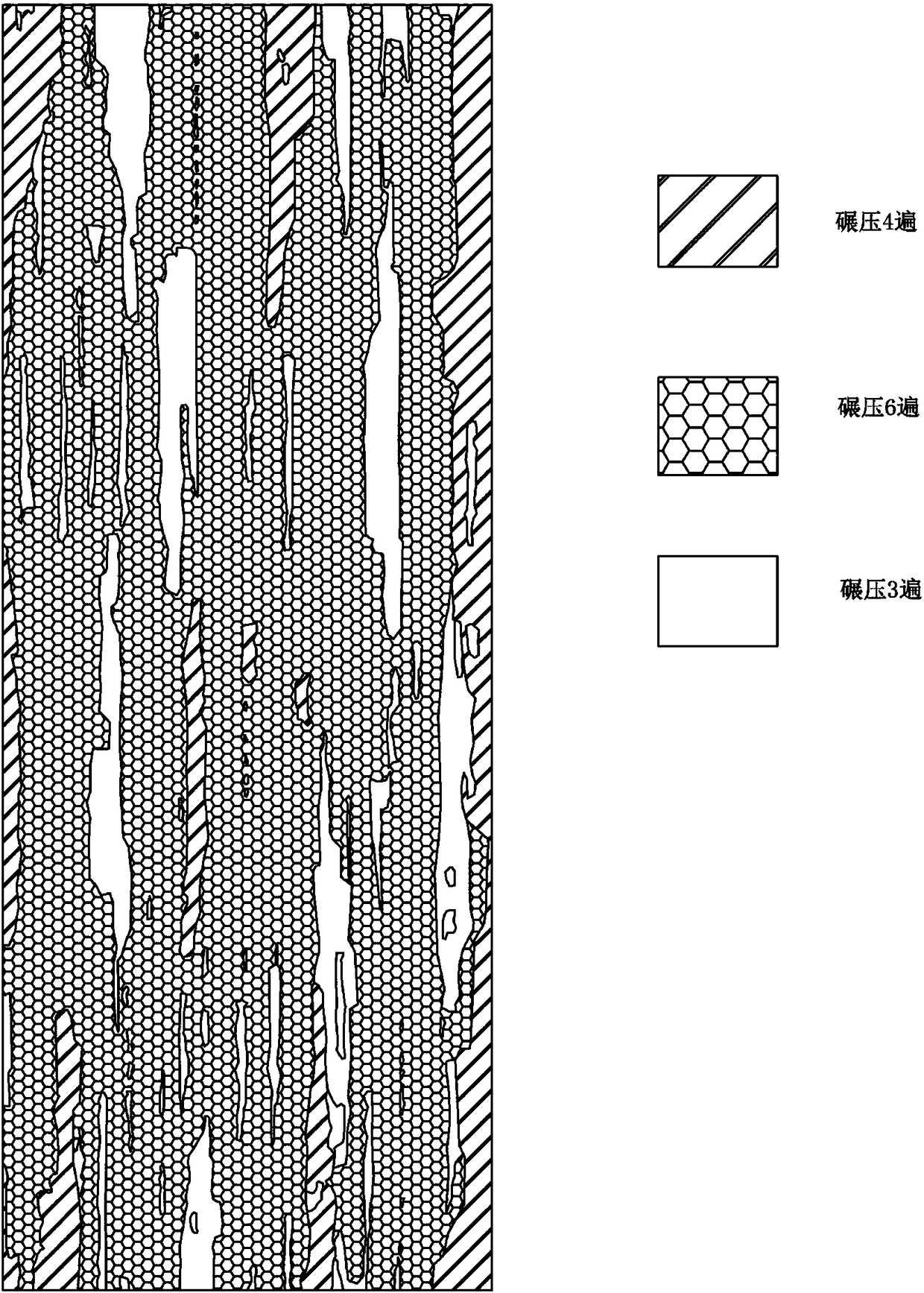

[0030] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] A roadbed rolling monitoring system based on RGB algorithm, comprising:

[0032] At least one road roller, and each road roller is equipped with a data acquisition module and a vehicle-mounted terminal. The data acquisition module uses a three-constellation GNSS positioning module to accurately locate the real-time three-dimensional coordinates of the road roller, as well as the position and area of road paving through network RTK technology Data collection, where the data positioning modules on each roller are connected to each other; the vehicle-mounted terminal is connected to the server, and can request the rolling status or rolling results to the server in real time;

[0033] The data upload communication module uploads the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com