Power generation device based on liquid thermal energy conversion

A technology for thermal energy conversion and power generation devices, which is applied in steam engine devices, machines/engines, steam applications, etc., and can solve the problems of low thermal efficiency, high energy consumption, and low efficiency in nuclear power plants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

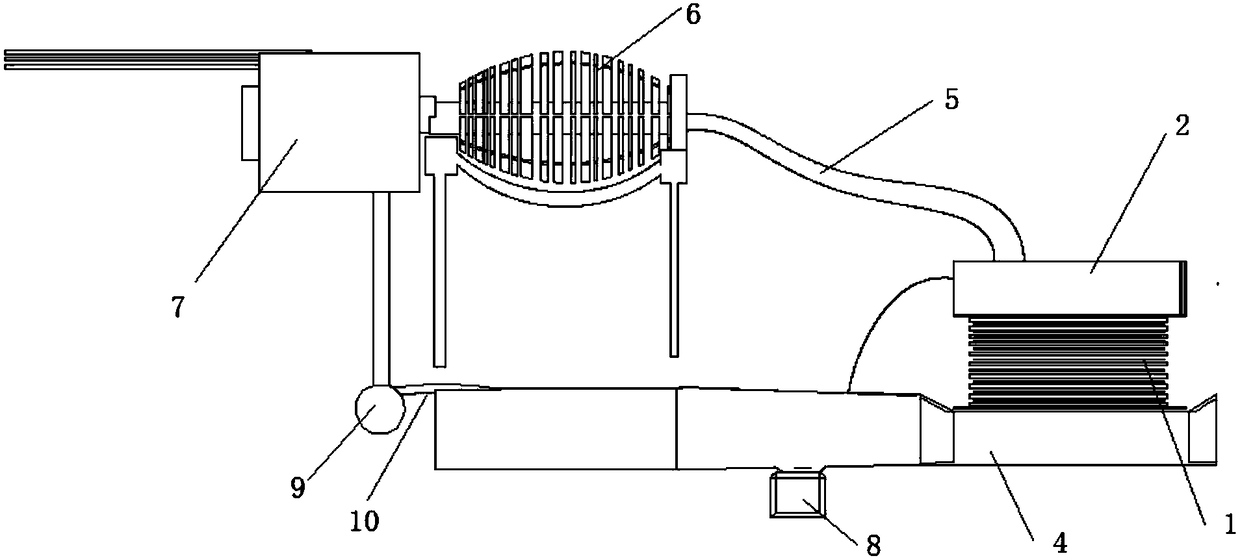

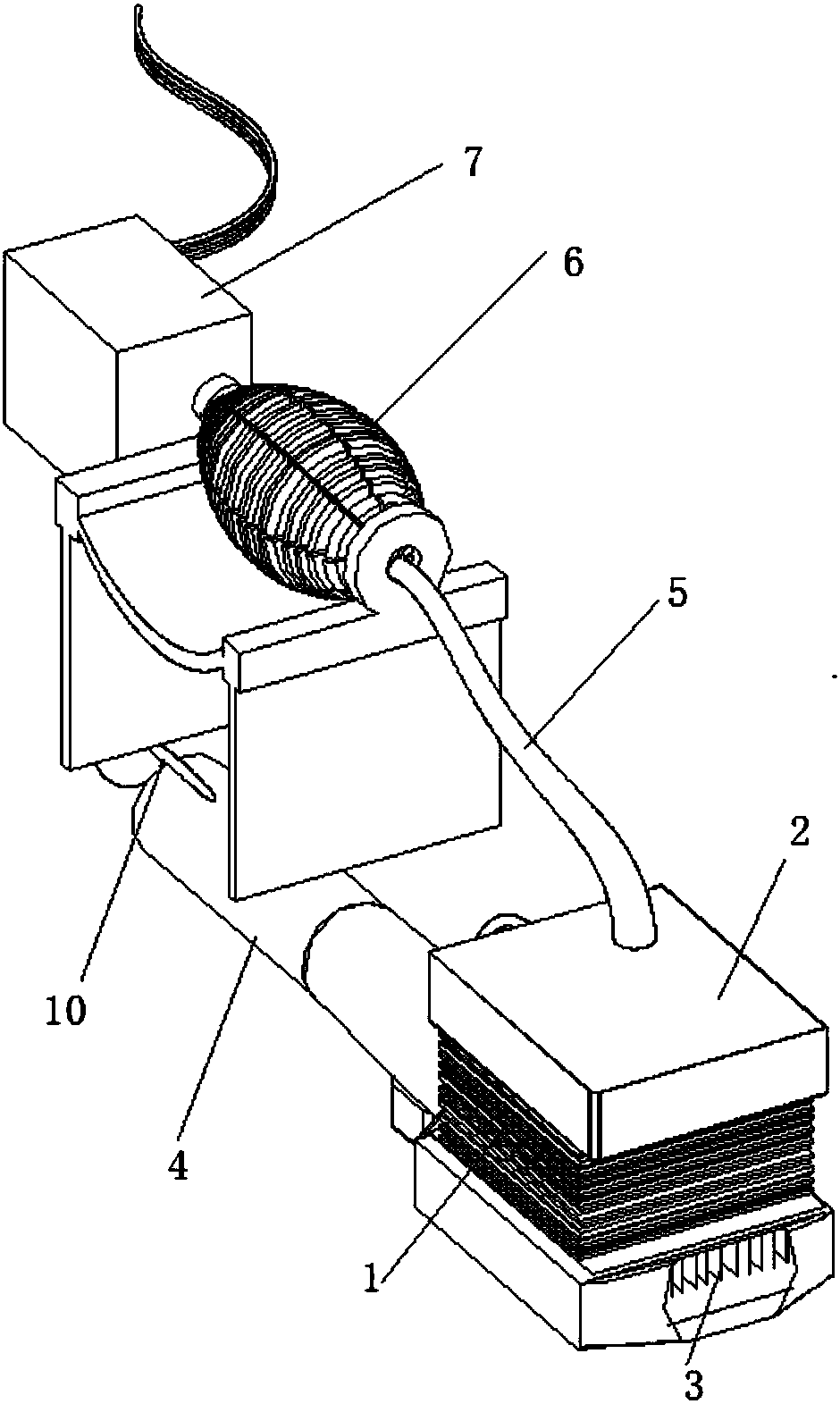

[0024] Embodiment 1, see attached figure 1 , 2 , a power generation device based on liquid thermal energy conversion, which includes: a steam turbine engine 6, a generator 7, a heat pump body 1, a steam generator 2 and a water pipe 4;

[0025] The heat pump body 1 is composed of superimposed temperature difference sheets, and a heat transfer sheet 3 is provided between adjacent temperature difference sheets and at the bottom of the bottom temperature difference sheet; the heat pump body 1 is divided into a lower cooling end and an upper heating end;

[0026] The water pipe 4 is provided with an opening, and the bottom end of the heat pump body 1 extends into the water pipe 4 from the opening. touch;

[0027] The steam generator 2 is a metal box, which is filled with pure water; the heating end of the heat pump body 1 is in contact with the bottom of the steam generator 2, and is used to heat the pure water in the steam generator 2 to vaporize it; the steam generator 2 Conne...

Embodiment 2

[0033] Embodiment 2, on the basis of Embodiment 1, specific limitations are made to the heat transfer sheet 3, the heat pump body 1, the steam generator 2 and the water conduit 4;

[0034] The heat transfer sheet 3 is a copper sheet with good thermal conductivity, the thickness of the heat transfer sheet 3 between adjacent temperature difference sheets is 10mm, and the thickness of the bottom heat transfer sheet 3 is 100mm or more;

[0035] The size of the steam generator 2 is 9.1×9.1×2m;

[0036] The temperature of the liquid in the water pipe 4 is about 20°C, and the temperature drops to 1-5°C after passing through the cooling end of the heat pump body 1; in order to ensure the heat absorption effect, a flow regulating valve is installed on the water pipe 4 to adjust the flow rate. The opening of the valve can control the flow of liquid in the water pipe 4, thereby ensuring the transfer of heat;

[0037] The heat pump body 1 is composed of nine 9×9-meter temperature differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com