Power splitting tension loading test equipment suitable for CT scan

A technology of loading test and CT scanning, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of introducing CT scanning instruments, to ensure the accuracy of load control and solve the problem of excessive spatial scale Small, low friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 A description of the structure of a dynamic split-pull loading test device suitable for CT scanning according to the present invention

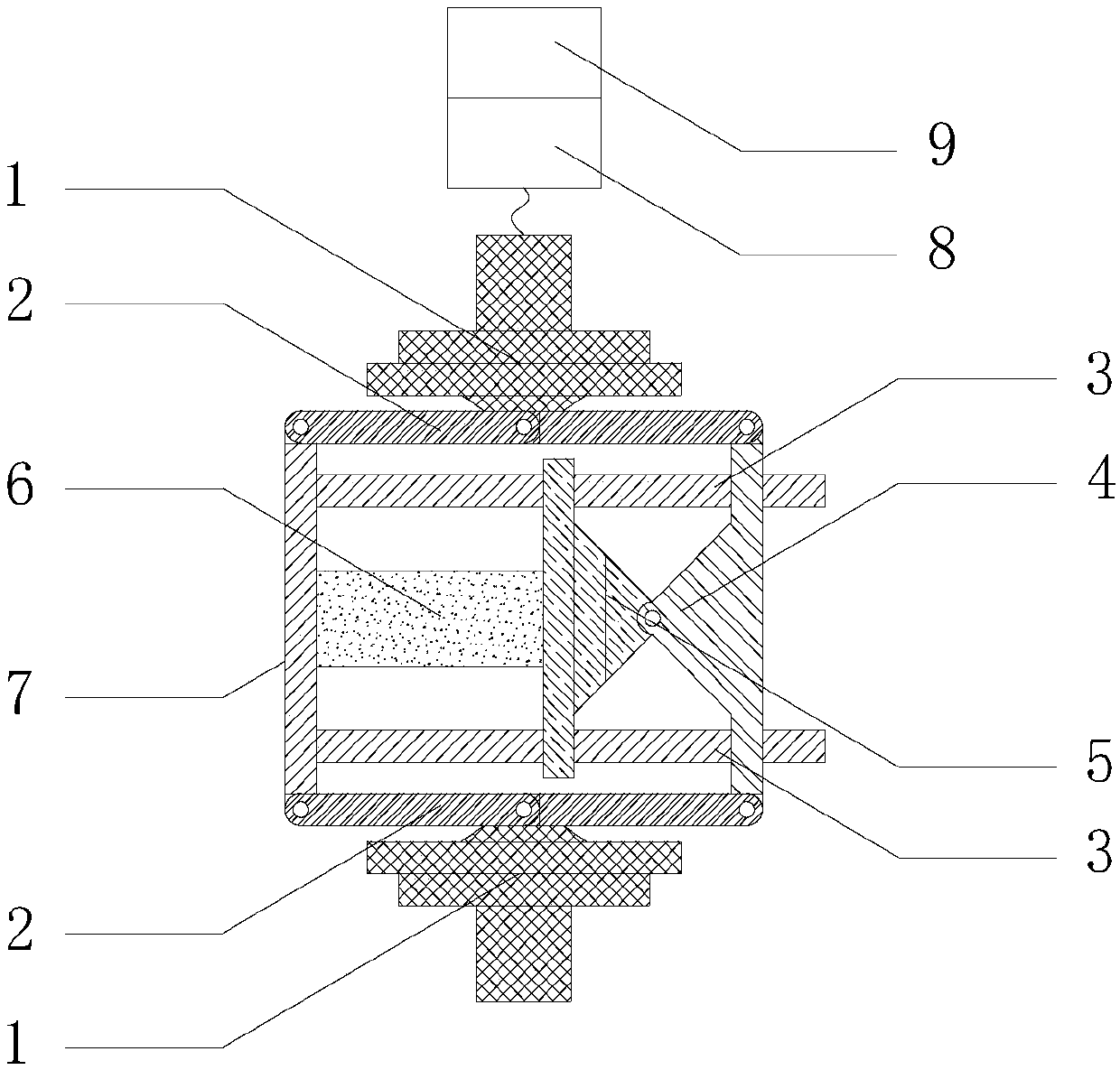

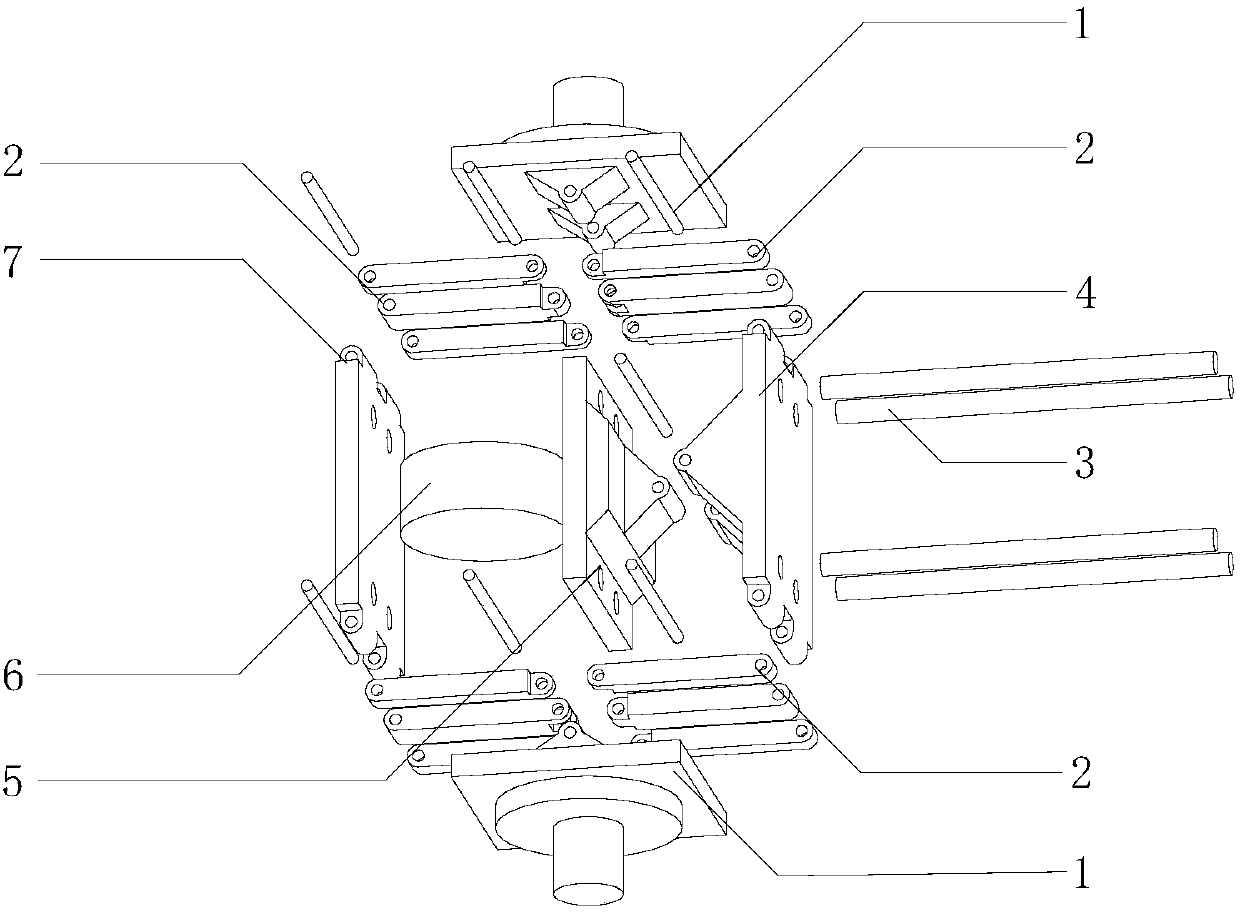

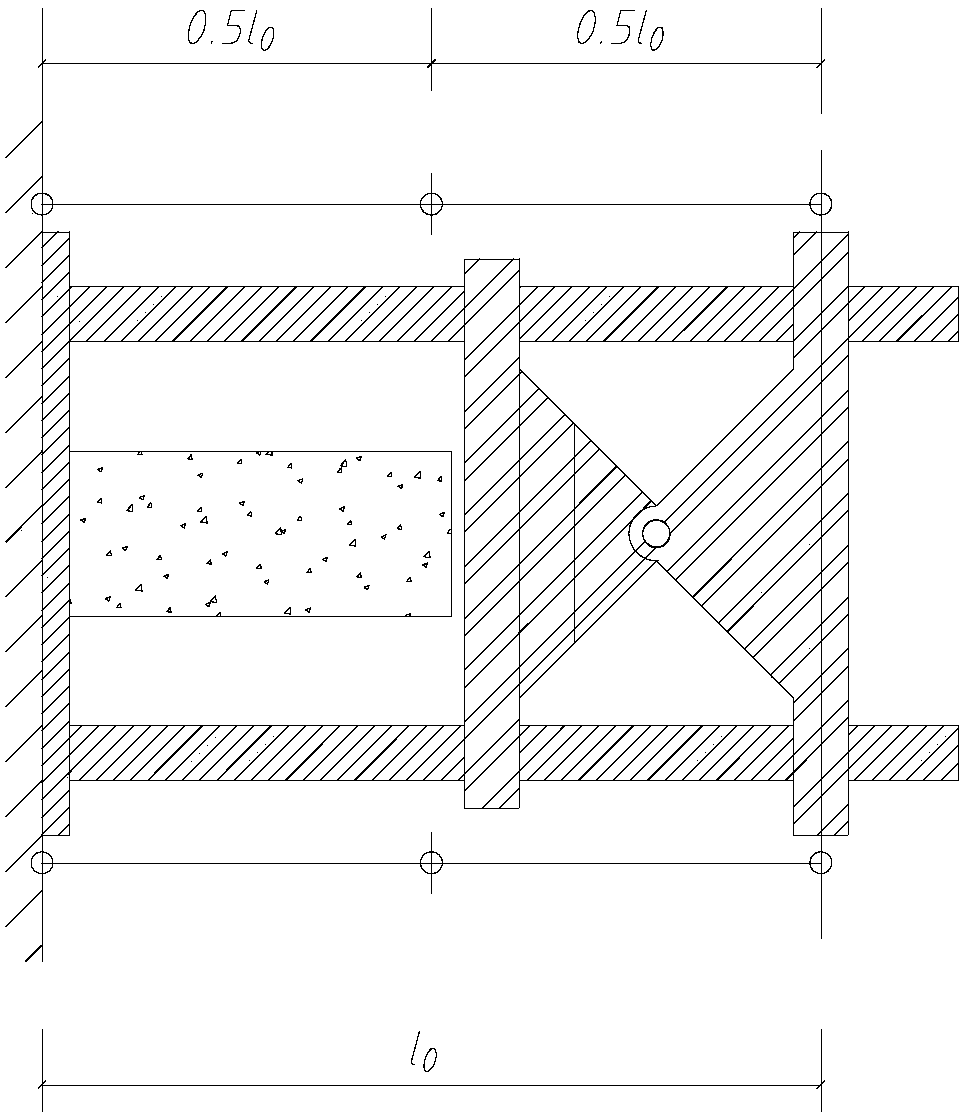

[0026] Such as figure 1 , figure 2 As shown, a dynamic split-pull loading test equipment suitable for CT scanning includes a tension platform 1, a tension-compression conversion mechanism 2, a steel rod 3, a pressure platform (pressing end) 4, a universal head 5, a specimen 6, Constraint platform (fixed end) 7, load and displacement sensor 8, computer control system 9.

[0027] The hydraulic stretcher, pressure and displacement sensors 8 and computer control system 9 connected externally to the tension platform 1 constitute the load application control system of the equipment.

[0028] The tension platform 1 and the pressure platform 4 are connected through the tension-compression conversion mechanism 2, and the tension-compression conversion mechanism 2 transmits the load of the tension platform 1 to the pressure platf...

Embodiment 2

[0034] Embodiment 2 A method of using the dynamic splitting and pulling loading test equipment suitable for CT scanning according to the present invention

[0035] The specific test steps are as follows:

[0036] Step 1, place and adjust the equipment: fix the equipment constraining platform 7 on the bed of the CT scanner, and adjust so that the length direction of the steel rod 3 is parallel to the direction of the scanning section;

[0037] Step 2, installation of the loading and measuring system: connect the hydraulic tensioner to the tension platform 1 at both ends, install the pressure and displacement sensor 8 and connect it to the computer;

[0038] Step 3, setting of experimental parameters: select the control loading mode of the test (load control or displacement control), set the initial parameters (displacement initial parameters x 0 or the initial parameter of the force F 0 , for pre-clamping specimens), incremental parameters (displacement incremental paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com