A kind of semiconductor power device and its manufacturing method

A technology of power devices and semiconductors, applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as poor reliability of curved structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

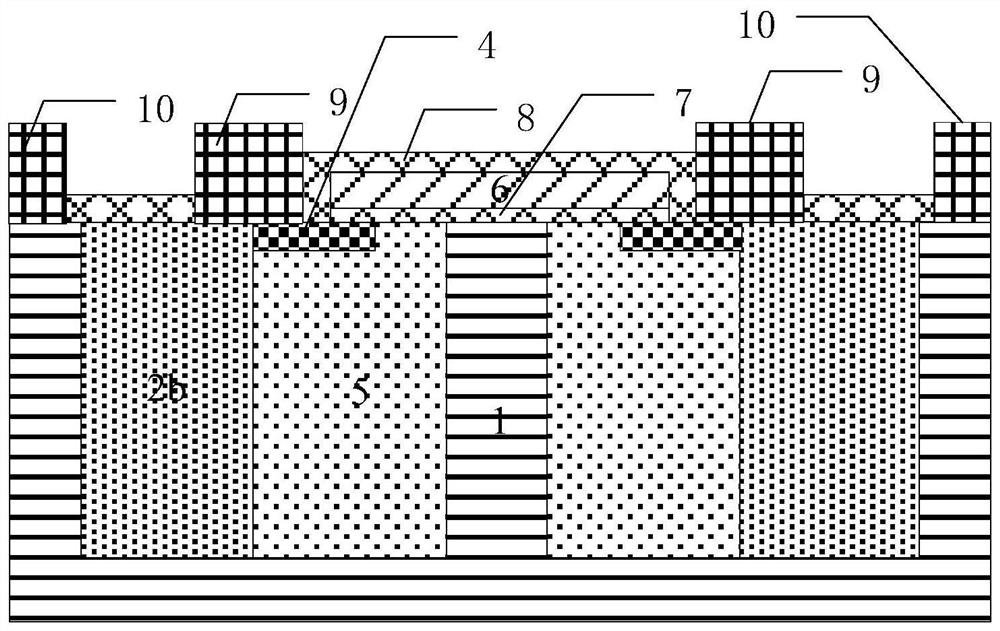

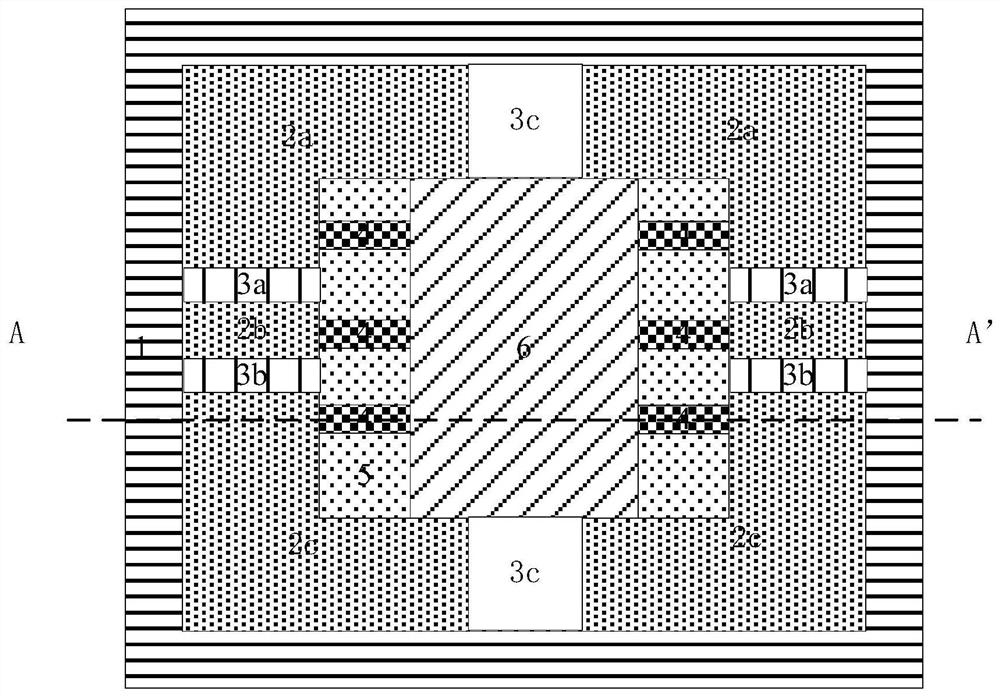

[0042] see figure 1 and figure 2 , a cross-sectional view and a top view of a semiconductor power device provided by an embodiment of the present invention. A semiconductor power device provided by an embodiment of the present invention includes: an N-type substrate, an N+ region 1, a P-body region 5, a PN alternating superjunction region, an N+ source region 4, a gate oxide layer 7, and a polysilicon gate 6 , Dielectric layer isolation 8, device source metal 9 and device drain metal 10. Wherein, the N+ region is an electron drift region composed of a central region, a bottom region and a side region. The cross-section of the side area is "mouth", the cross-section of the central area is "one", located in the center of the side area, and the bottom area is square, located at the bottom of the device.

[0043] The top of the N-type substrate is connected to the bottom edge region of the N+ region, the inner surface of the N+ region extends to the central region to form a P-...

Embodiment 2

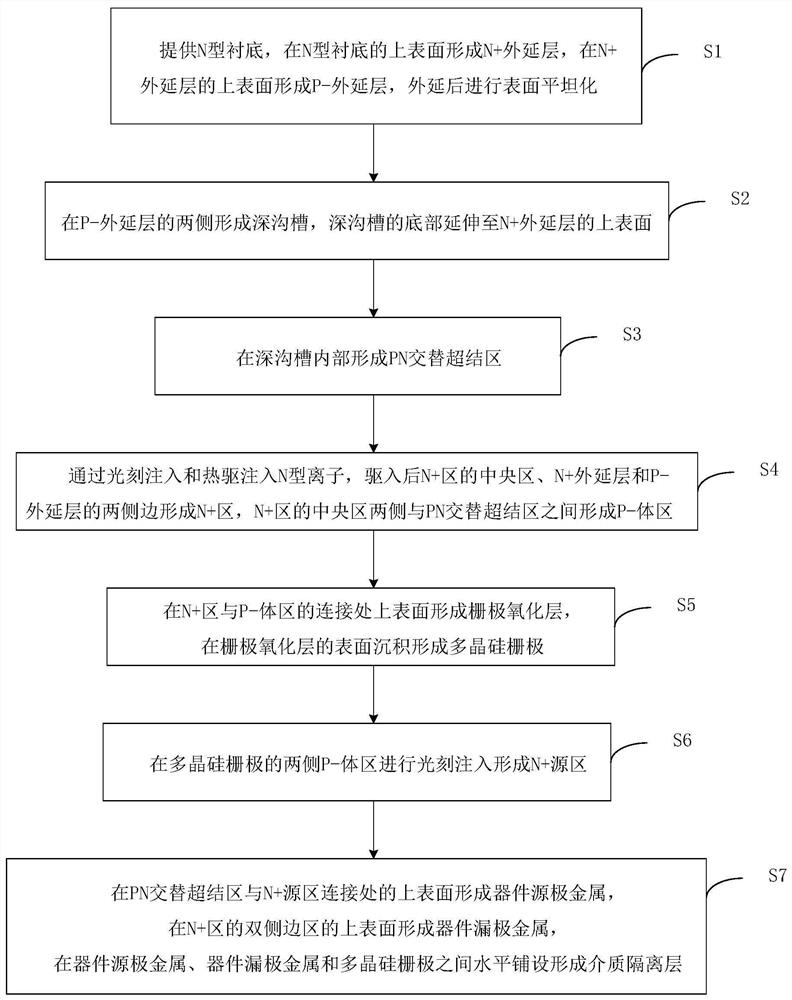

[0054] see image 3 , a flowchart of a method for manufacturing a semiconductor power device provided by an embodiment of the present invention. A method for manufacturing a semiconductor power device provided by an embodiment of the present invention includes the following steps:

[0055] Step S1: providing an N-type substrate, forming an N+ epitaxial layer on the upper surface of the N-type substrate, forming a P- epitaxial layer on the upper surface of the N+ epitaxial layer, and performing surface planarization after epitaxy. see Figure 4 , a product schematic diagram of step S1 in the method for manufacturing a semiconductor power device provided by an embodiment of the present invention.

[0056] Step S2: forming deep trenches on both sides of the P- epitaxial layer, the bottom of the deep trenches extending to the upper surface of the N+ epitaxial layer. see Figure 5 , a product schematic diagram of step S2 in the method for manufacturing a semiconductor power dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com