Multi-layer plate drying device

A drying device and plate technology, applied in drying, drying machine, electrode manufacturing, etc., can solve problems affecting battery quality, uneven distribution of electrode paste, limited number of plates, etc., to improve drying efficiency, Effect of improving battery quality and extending battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

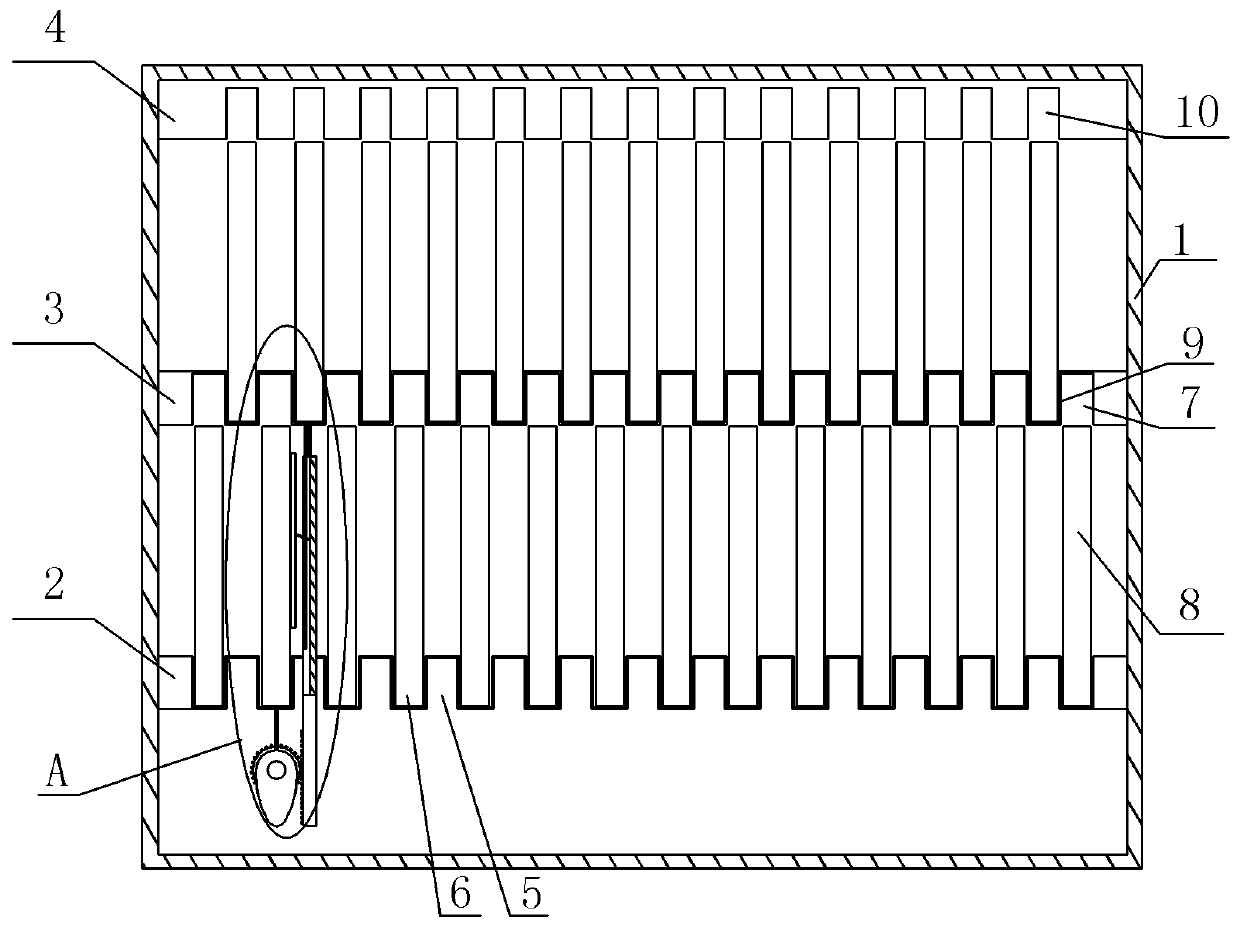

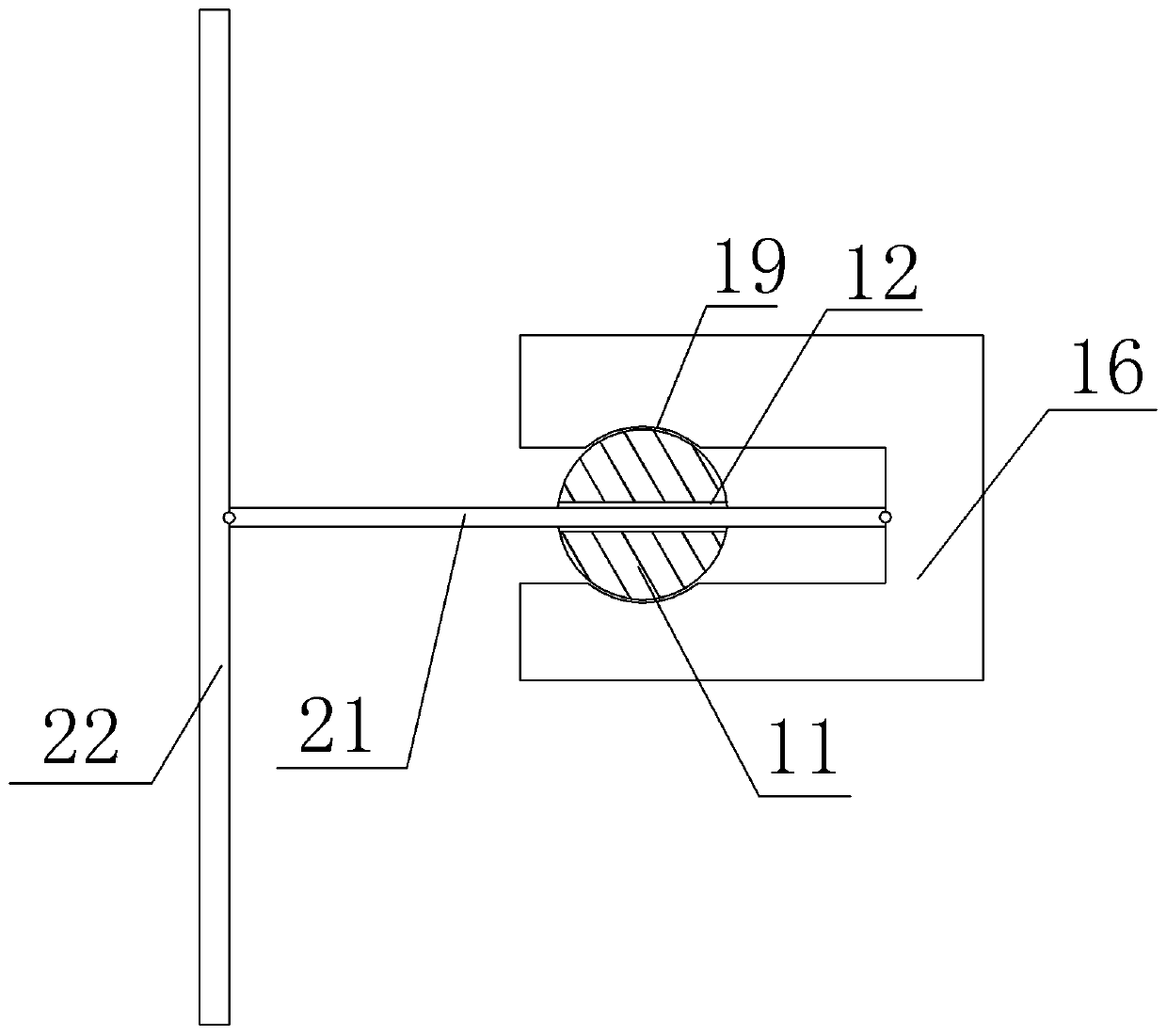

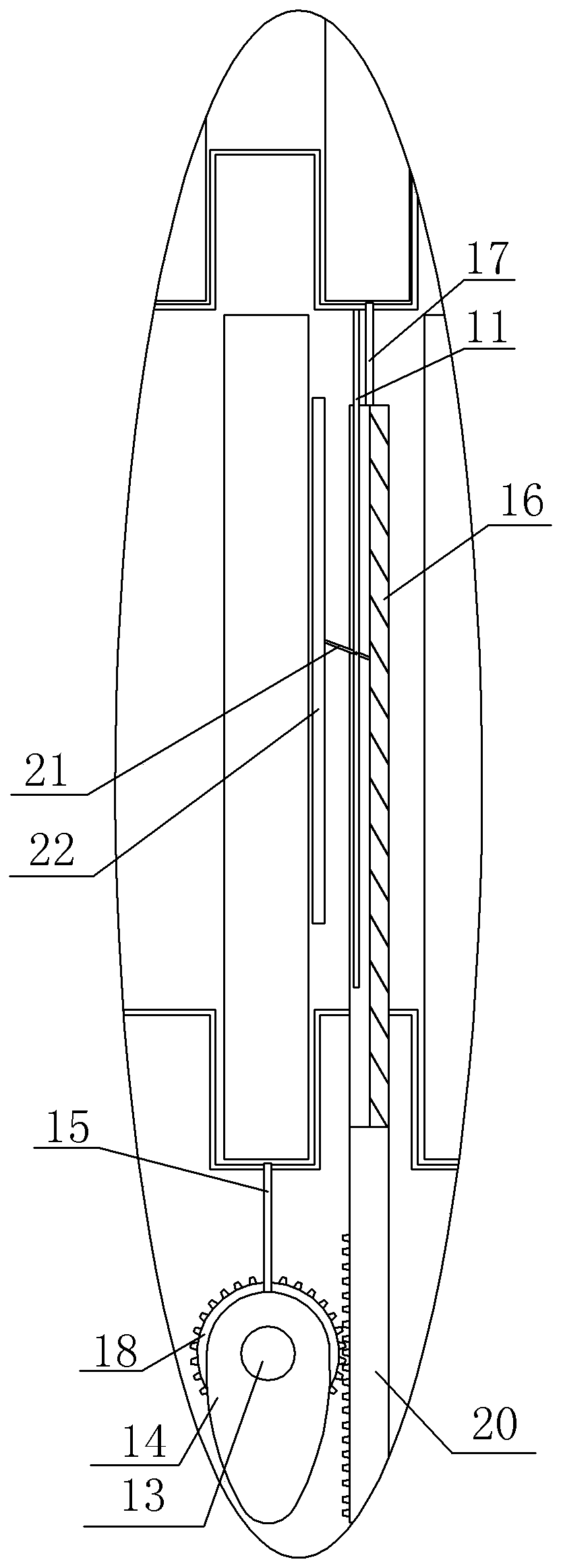

[0018] Further detailed explanation through specific implementation mode below:

[0019] The reference signs in the accompanying drawings of the specification include: oven 1, first layer of partitions 2, second layer of partitions 3, third layer of partitions 4, first containing groove 5, first limiting groove 6, second layer of partitions Two accommodation grooves 7, pole plates 8, second limiting grooves 9, third accommodation grooves 10, guide rods 11, holes 12, rotating shafts 13, cams 14, first lifting rods 15, support bars 16, second top Lifting rod 17, gear 18, arc groove 19, rack 20, extruding troweling rod 21, extruding troweling plate 22.

[0020] Such as figure 1 The multi-layer electrode plate drying device shown includes a baking oven 1, a jacking mechanism and an extruding and smoothing mechanism. The oven 1 is provided with a first layer of partitions 2, a second layer of partitions 3 and a third layer of partitions 4 from bottom to top, and the first layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com