Process for making gold velvet picture

A technology of gold velvet and craftsmanship, applied in the field of non-inverted material drawing, can solve the problems that the characteristics of the gold velvet material cannot be fully utilized, cover up the texture, and suppress the three-dimensional effect of the picture, so as to facilitate mass production line production, strong three-dimensional effect, Obvious effect of visual impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

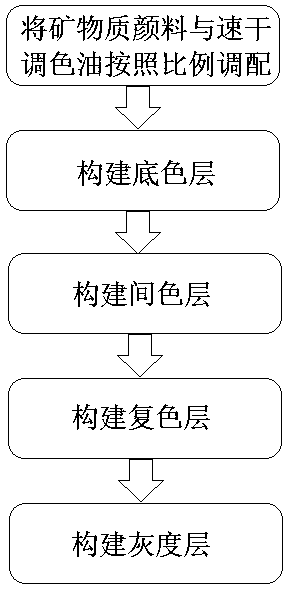

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a process for making gold velvet paintings. This process can be aimed at the gold velvet material. When the light hits the flannelette, it will produce a special physical characteristic of light wrapping color to draw a picture. .

[0027] The process includes the following steps:

[0028] Step 1: Mix mineral pigments and quick-drying toning oil according to the ratio, and the amount of quick-drying toning oil is greater than the amount of mineral pigments;

[0029] Step 2: Print the outline of the object image to be expressed on the golden velvet material with the mineral pigment prepared with quick-drying toning oil to form the base color layer;

[0030] Step 3: use two primary colors to mix the secondary color, and print the mixed secondary color on the base color layer to form the secondary color layer;

[0031] Step 4: Blend the secondary color with the secondary color to form a secondar...

Embodiment 2

[0038] In this embodiment, the mineral pigment is an ocher pigment, and the ratio of the mineral pigment to the quick-drying toning oil is 2-4:6-8.

[0039] The preferred ratio of mineral pigments to quick-drying toning oil is 3:7.

[0040] It also includes step four,

[0041] Said step four: use neutral pigment to dilute the coal agent to trace the outline of the painted object.

[0042] When the black pigment is removed from the neutral pigment, the neutral pigment dilutes the coal medium agent specifically as follows: neutral pigment: medium agent: water is 3:2:5, or neutral pigment: medium agent: water is 2:1:5 .

[0043] The medium agent includes: one or more combinations of turpentine oil, toner oil, and varnish oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com