A kind of wood furniture coating and preparation method thereof

A technology for wood furniture and coatings, applied in rosin coatings, anti-corrosion coatings, dry oil coatings, etc., can solve problems such as adverse human health, and achieve beautiful visual effects, soft visual effects, and good scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

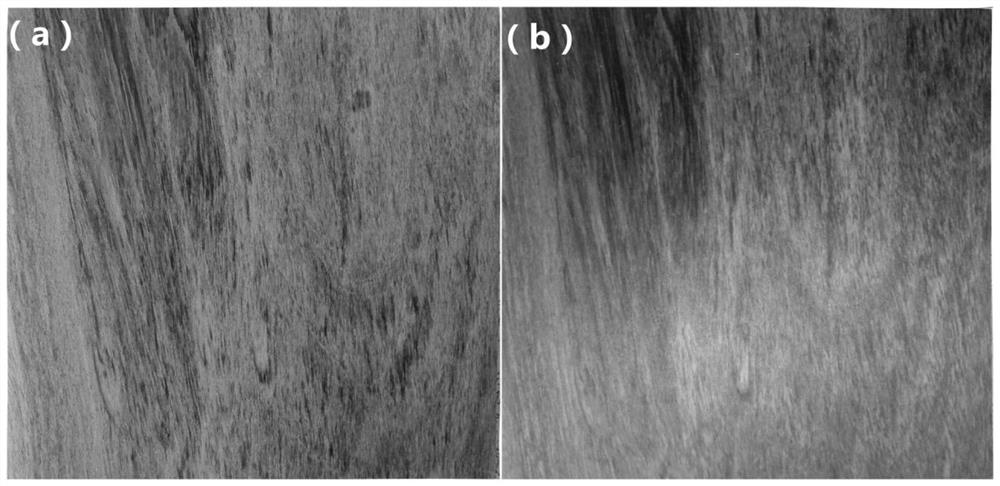

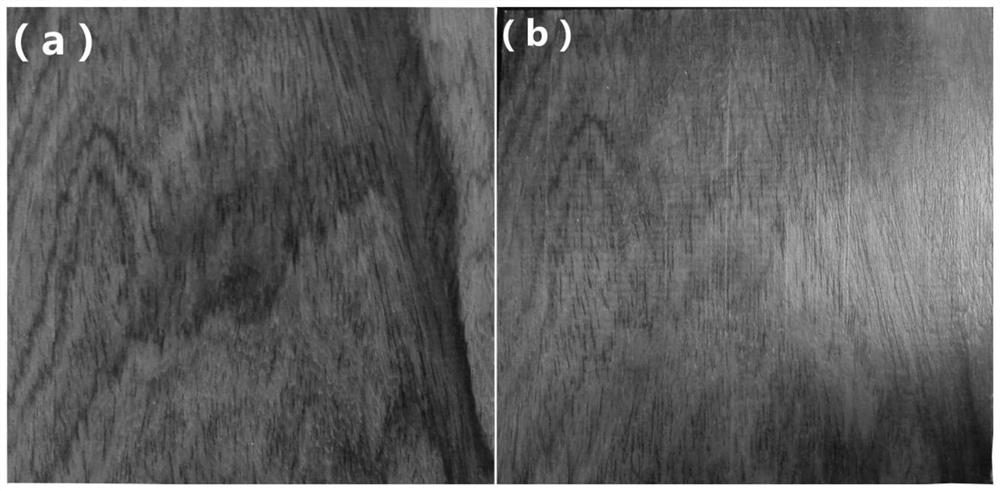

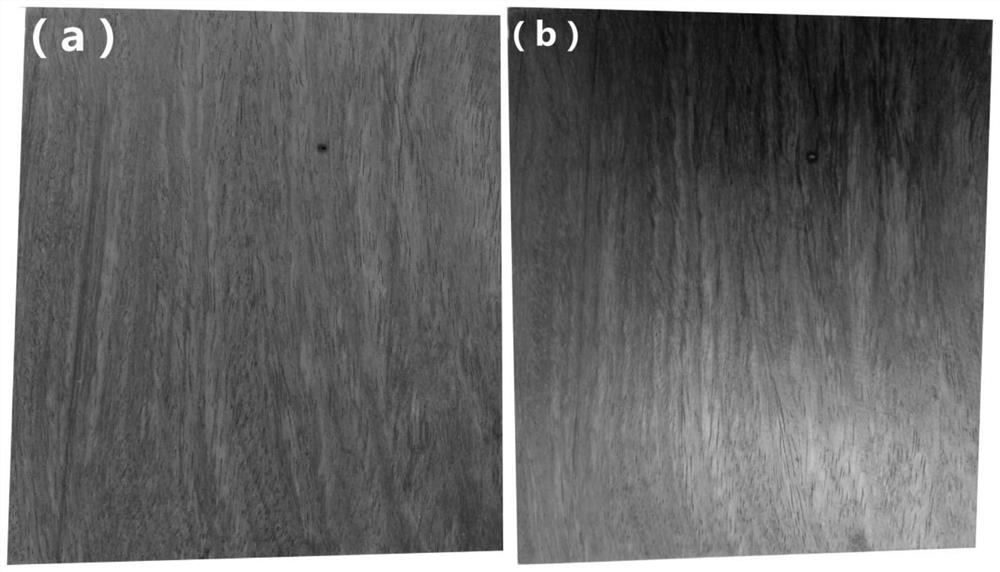

Image

Examples

Embodiment 1

[0026] A preparation method of wood furniture coating, the operation steps are as follows:

[0027] (1) take by weighing the following components according to mass percentage: 1% of gloss-preserving anti-scratch wax powder, 5% of rosin glycerin resin, 50% of mixed oil, 44% of turpentine; wherein, the mixed oil is tung oil, linseed oil and catalpa oil according to the quality Mixed in a ratio of 2:1:1;

[0028] (2) Weighing the obtained gloss-preserving anti-scratch wax powder and rosin glycerin resin in step (1) and dissolving in turpentine at 95°C, mixing uniformly, adding mixed oil, stirring uniformly, to obtain wood furniture coating.

Embodiment 2

[0030] A preparation method of wood furniture coating, the operation steps are as follows:

[0031] (1) take by weighing following components according to mass percentage: polyethylene wax powder 12%, male rosin resin 10%, mixed oil 48%, turpentine 30%; wherein, mixed oil is tung oil, linseed oil and catalpa oil according to the quality The ratio is 2.5:1.5:0.5 mixed;

[0032] (2) The polyethylene wax powder and malerosin resin obtained in step (1) were weighed and dissolved in turpentine at 90° C., mixed uniformly, added the mixed oil, and stirred uniformly to obtain a wood furniture coating.

Embodiment 3

[0034] A preparation method of wood furniture coating, the operation steps are as follows:

[0035] (1) take by weighing following components according to mass percentage: 285 wax pulp 6%, rosin glycerin resin 15%, mixed oil 45%, turpentine 34%; Wherein, mixed oil is tung oil, linseed oil and catalpa oil according to mass ratio 1.5: 0.5:1.5 mixed;

[0036] (2) 285 wax slurry and rosin glycerin resin obtained in step (1) were weighed and dissolved in turpentine at 100° C., mixed uniformly, added mixed oil, and stirred uniformly to obtain wood furniture coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com