Plate special for luminous characters and preparing method thereof

A technology of luminous characters and light-transmitting layers, applied in chemical instruments and methods, applications, household appliances, etc., can solve the problems of not energy saving and environmental protection, long construction period, complicated manufacturing process, etc., to achieve low cost, reduce intermediate links, The effect of low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

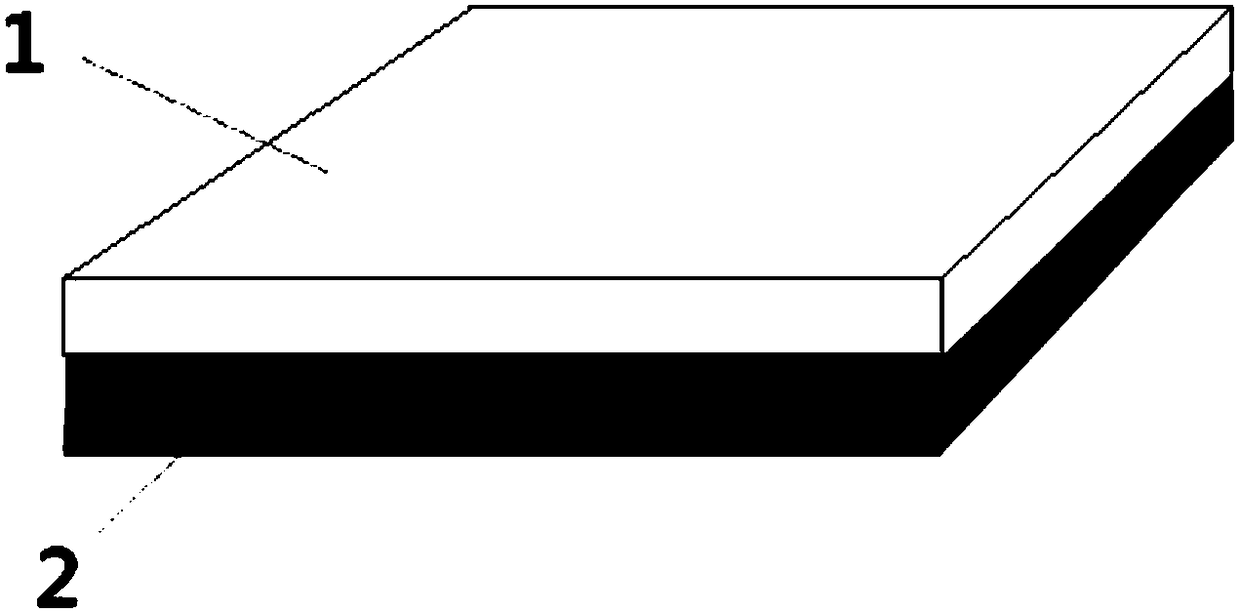

[0025] Such as figure 1 with 2 As shown, a special board for luminous characters includes a light guiding layer 1 and an opaque layer 2 . The luminous special board is made of epoxy AB mixed resin. The manufacturing process includes the following steps: prepare a prefabricated board abrasive tool, and pour the first layer of epoxy resin with a thickness of 2 cm. Add 5% oily color paste by weight of epoxy resin, light calcium powder with 50% weight of epoxy resin, and talc powder with 10% weight of epoxy resin in the epoxy resin to increase the strength, improve toughness and reduce cost. After waiting 8 hours for the surface to basically solidify and form, form an opaque layer 2, then pour the second layer of 1 cm thick mixed epoxy resin, and add light guide powder 2 with 5% of the weight of epoxy resin to the second layer of epoxy resin Silicon oxide, the second layer of oily color paste with 0.8% epoxy resin weight, wait for 24 hours for the second layer of resin to cure a...

Embodiment 2

[0029] Such as figure 1 with 2 As shown, a special board for luminous characters includes a light guiding layer 1 and an opaque layer 2 . The luminous special board is made of unsaturated resin, and the manufacturing process includes the following steps: prepare a prefabricated board mold, and pour the first layer of 2 cm thick unsaturated resin. Among them, add 5% oily color paste of unsaturated resin weight to unsaturated resin, add light calcium powder with 50% weight of unsaturated resin, add talc powder with 10% weight of unsaturated resin, to increase strength and improve toughness, while reducing cost. After waiting for 20 minutes to solidify and form, an opaque layer 2 is formed, and then the second layer of unsaturated resin with a thickness of 1 cm is poured. It is necessary to mix the second layer of unsaturated resin with light-guiding powder silica of 5% by weight. The second layer does not Saturate the oil-based color paste with 0.8% weight of the resin, wait ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com