Glass cooling device

A cooling device and glass technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of reduced material utilization rate, quality defects of special glass products, difficult to form mold temperature uniform cooling, etc., to improve cooling Efficiency, better quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

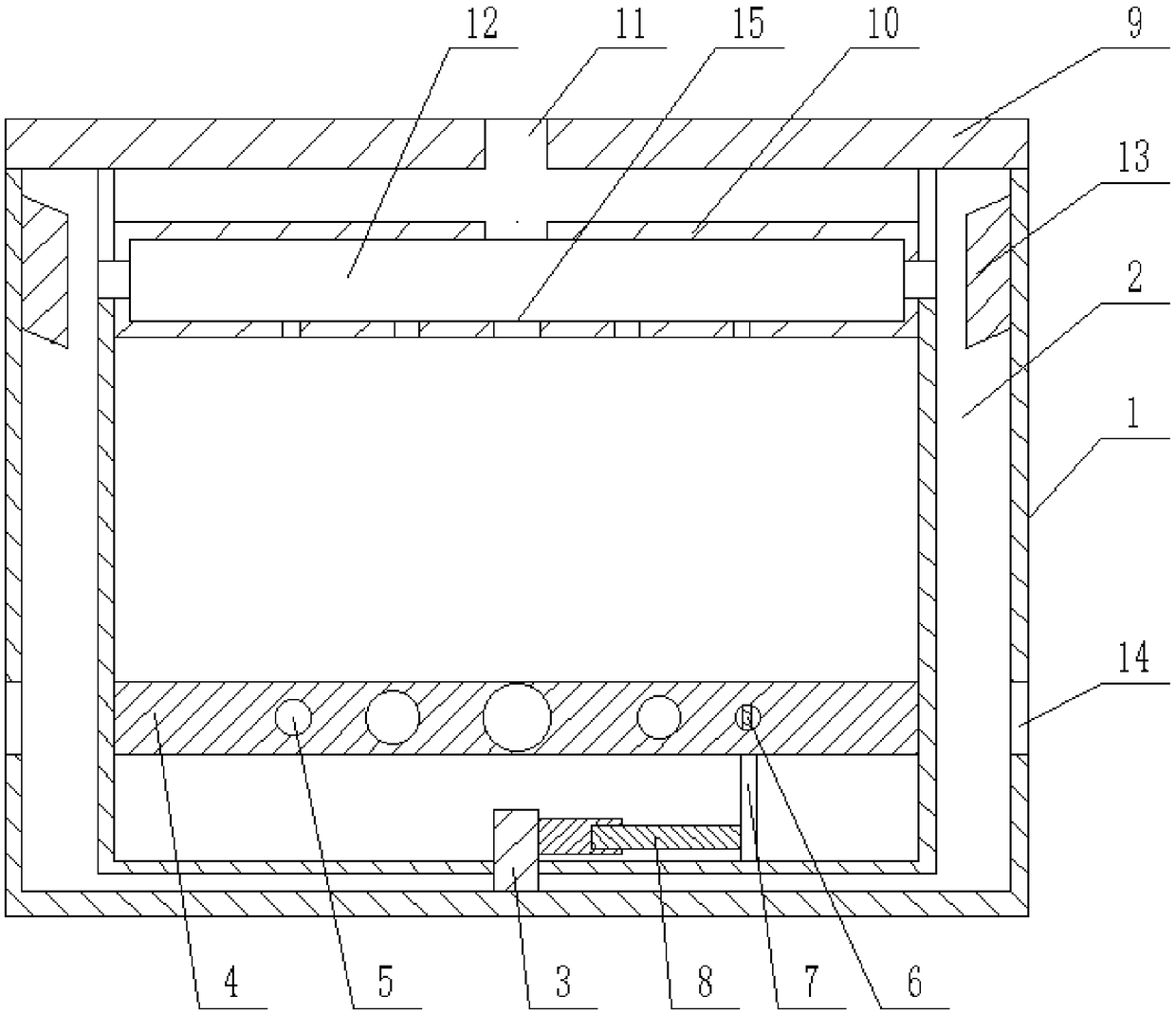

[0022] Glass cooling unit, if attached figure 1 As shown, it includes a mold 1, a ventilation mechanism and a cooling mechanism installed in the mold 1. The side wall of the mold 1 is provided with a conduction chamber 2, and the center of the bottom of the mold 1 is welded with a straight shaft 3.

[0023] The cooling mechanism includes a lower mold 4 for carrying glass. A spiral water pipe 5 whose diameter gradually decreases from the center is installed inside the lower mold 4. A water tank and a water pump are connected to the central nozzle of the spiral water pipe 5. The outer pipe of the spiral water pipe 5 The mouth is also connected with a sink and a water pump. The center position of the spiral water pipe 5 is directly opposite to the center position of the lower die 4. An iron block 6 is installed in the spiral water pipe 5. The bottom end of the lower die 4 is connected with a magnet 7 magnetically matched with the iron block 6, and the bottom end of the lower die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com