Low-lead release brass alloy

A brass alloy and master alloy technology, applied in the coating process of metal materials, etc., can solve the problems of organic film shedding and affecting the health of drinking people, and achieve the effects of reducing lead dissolution, inhibiting lead dissolution, and dense and firm oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

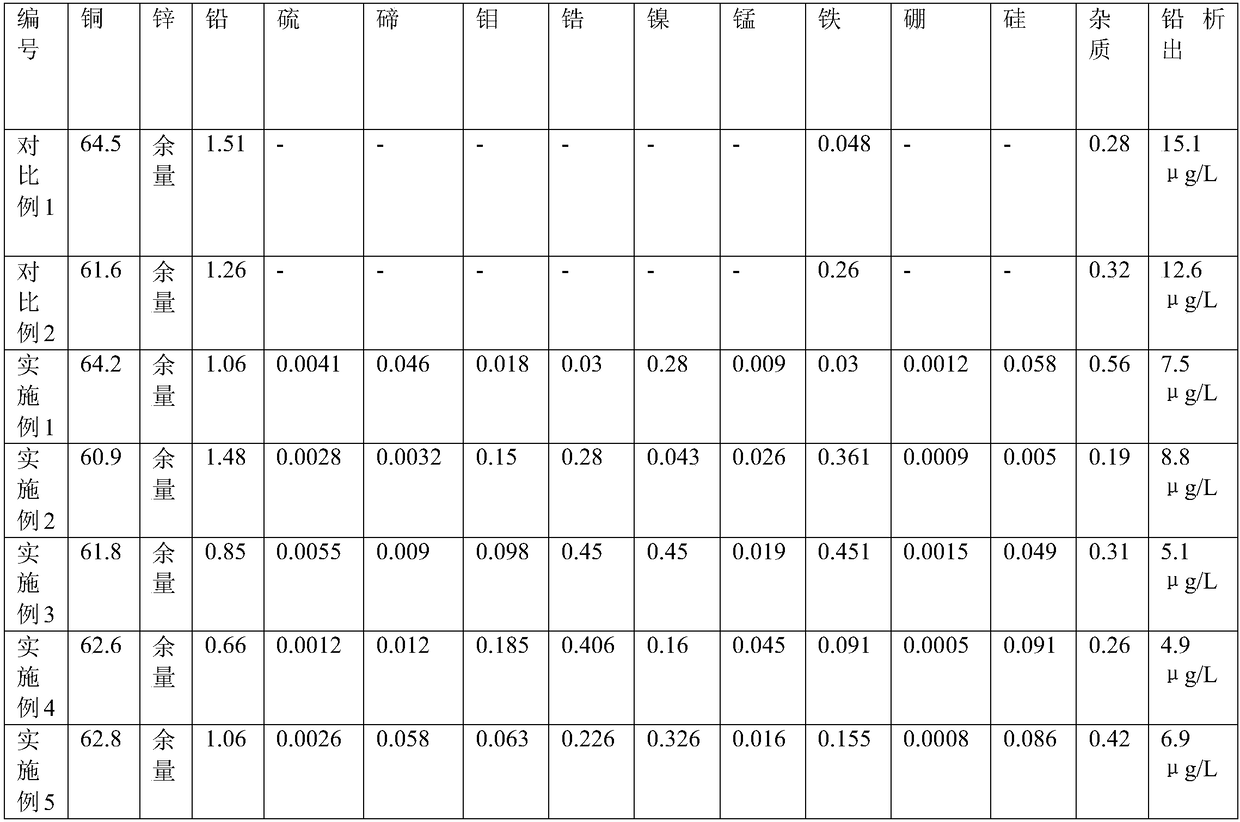

[0030] The alloy compositions of the samples of Examples 1-5 and Comparative Group 1 and Comparative Group 2 are shown in Table 1, and rods of Φ22 mm were manufactured.

[0031] The production process of the alloys listed in Table 1 is the same, try to ensure comparability. The production process is as follows:

[0032] (1) each component is batched according to proportioning;

[0033] (2) Heating to 1000-1050°C for smelting, using a horizontal continuous casting process to produce ingots;

[0034] (3) The ingot is heated up to 550°C, and then extruded in a 1350-ton extruder at an extrusion speed of 10mm / s, and the extruded billet is cooled and interrupted;

[0035] (4) The interrupted extruded billet is peeled to remove surface defects, then stretched, straightened, and subjected to stress relief annealing to obtain a finished brass alloy.

[0036] The surface of the brass alloy is passivated, and the passivation method comprises the following steps:

[0037] (a) Degreasi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap