Method for transforming lead glass into environment-friendly concrete raw material by using natural biological material

A technology of environmentally friendly concrete and biomaterials, applied in the field of environmentally friendly building materials, can solve the problems of unknown by-product lead content and treatment methods, CRT waste, damage to economic benefits, etc., and achieve economic feasibility and reduce lead leaching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

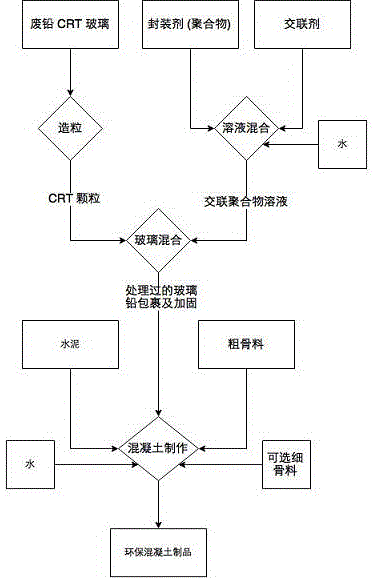

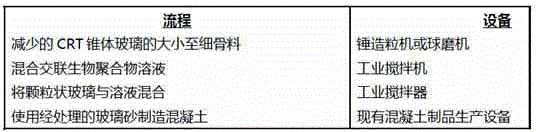

Method used

Image

Examples

Embodiment 1

[0039] 1. Prepare biopolymer solution.

[0040] Weigh 32g of locust bean gum and dissolve it in 1568g of water to obtain a 2%w / w locust bean gum solution.

[0041] 2. Prepare cross-linking agent solution.

[0042] Weigh 8g of crystalline boric acid and dissolve it in 392g of water to obtain a 2%w / w boric acid solution.

[0043] 3. Preparation of cross-linked biopolymer solution.

[0044] 1600 g of 2% w / w locust bean gum solution was mixed with 400 g of 2% w / w boric acid solution to obtain a cross-linked biopolymer solution.

[0045] 4. CRT lead glass treatment.

[0046] CRT lead glass is crushed and granulated, and the particle size after crushing is less than 1.5 mm. 10 kg of lead-containing glass is evenly coated and the solution is completely mixed until 100% of the particle size passes through a mesh of 1.5 mm.

[0047] 5. Preparation of concrete.

[0048] Mix 5kg of Portland cement, 10kg of treated CRT lead glass, and 15kg of stones with a particle size of 6-30mm, an...

Embodiment 2

[0054] 1. Prepare biopolymer solution.

[0055] Weigh 8g of guar gum and dissolve it in 792g of water to obtain a 1%w / w guar gum solution.

[0056] Weigh 8g of xanthan gum and dissolve it in 792g of water to obtain a 1%w / w xanthan gum solution.

[0057] Mix 1%w / w guar gum solution with 1%w / w xanthan gum solution at a ratio of 1:1 to obtain guar gum-xanthan gum biopolymerization solution.

[0058] 2. Prepare cross-linking agent solution.

[0059] Weigh 4g of 50%w / w glutaraldehyde stock solution and add it into 226g of water to obtain 0.9%w / w glutaraldehyde solution.

[0060] 3. Preparation of cross-linked biopolymer solution.

[0061] 1600 g of 1% w / w guar-xanthan gum biopolymer solution was mixed with 230 g of 0.9% w / w glutaraldehyde solution to obtain a cross-linked biopolymer solution.

[0062] 4. CRT lead glass processing.

[0063] CRT lead glass is crushed and granulated, and the particle size after crushing is less than 1.5 mm. 10 kg of lead-containing glass is evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap