A material with adjustable negative thermal expansion coefficient and its preparation method and application

A technology with negative coefficient of thermal expansion and coefficient of thermal expansion, which is applied in the field of materials with adjustable negative thermal expansion coefficient and its preparation and application, can solve problems such as narrow working temperature range, mechanical, heat conduction, and electrical conduction properties that need to be improved, and cannot be greatly adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

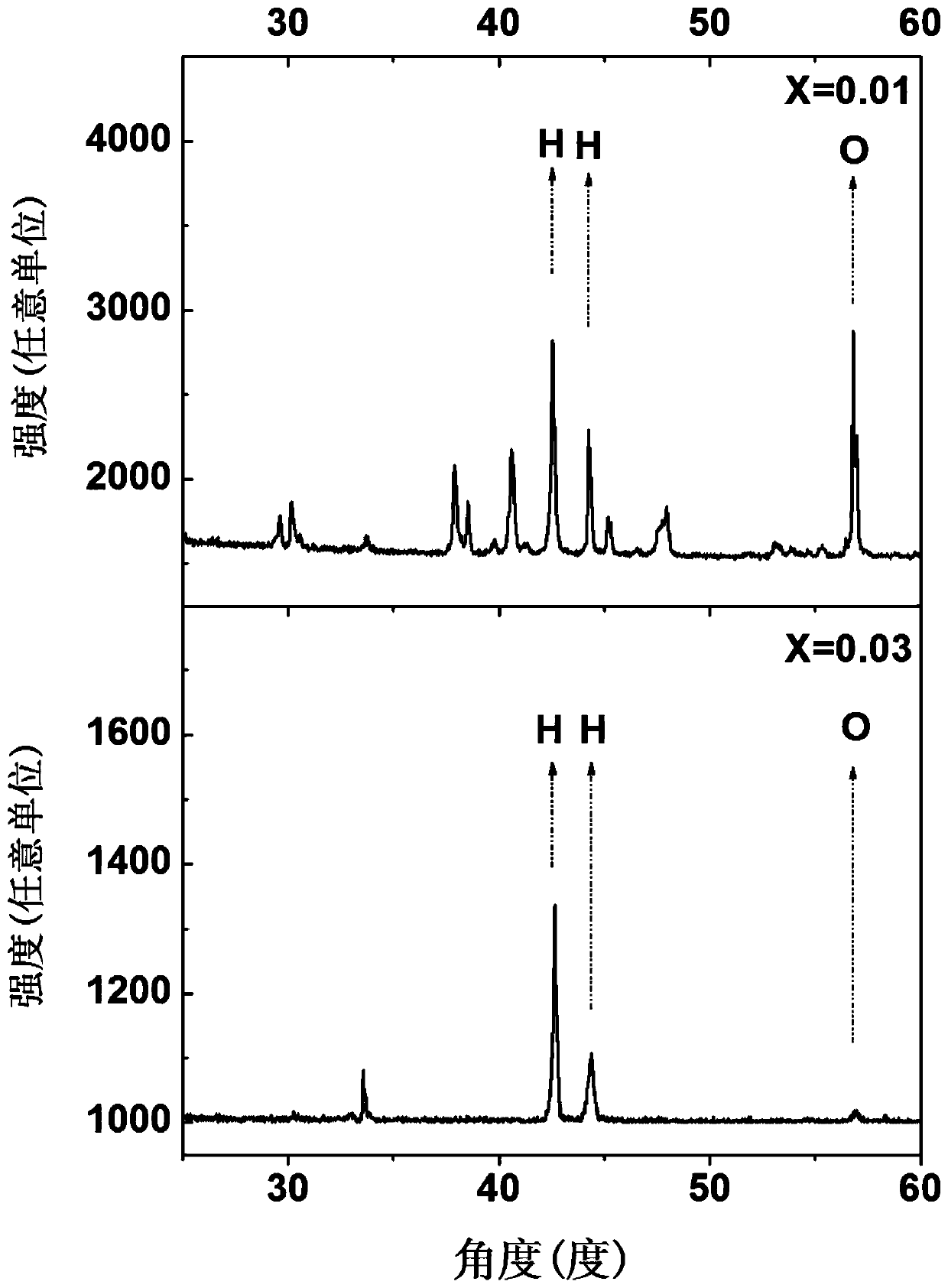

[0070] The composition of MnCoGe-based materials: Mn 1-x In x CoGe (x = 0.01, 0.03), the mass ratio of the balls in step 4) is 1:1, the epoxy resin in step 5) is 5%, the curing agent ratio is 8%, and the pressing conditions in step 6) are: Apply 1.3 GPa pressure and press for 5 minutes, and the curing conditions are: curing at 250°C for 1.5 hours.

Embodiment 2

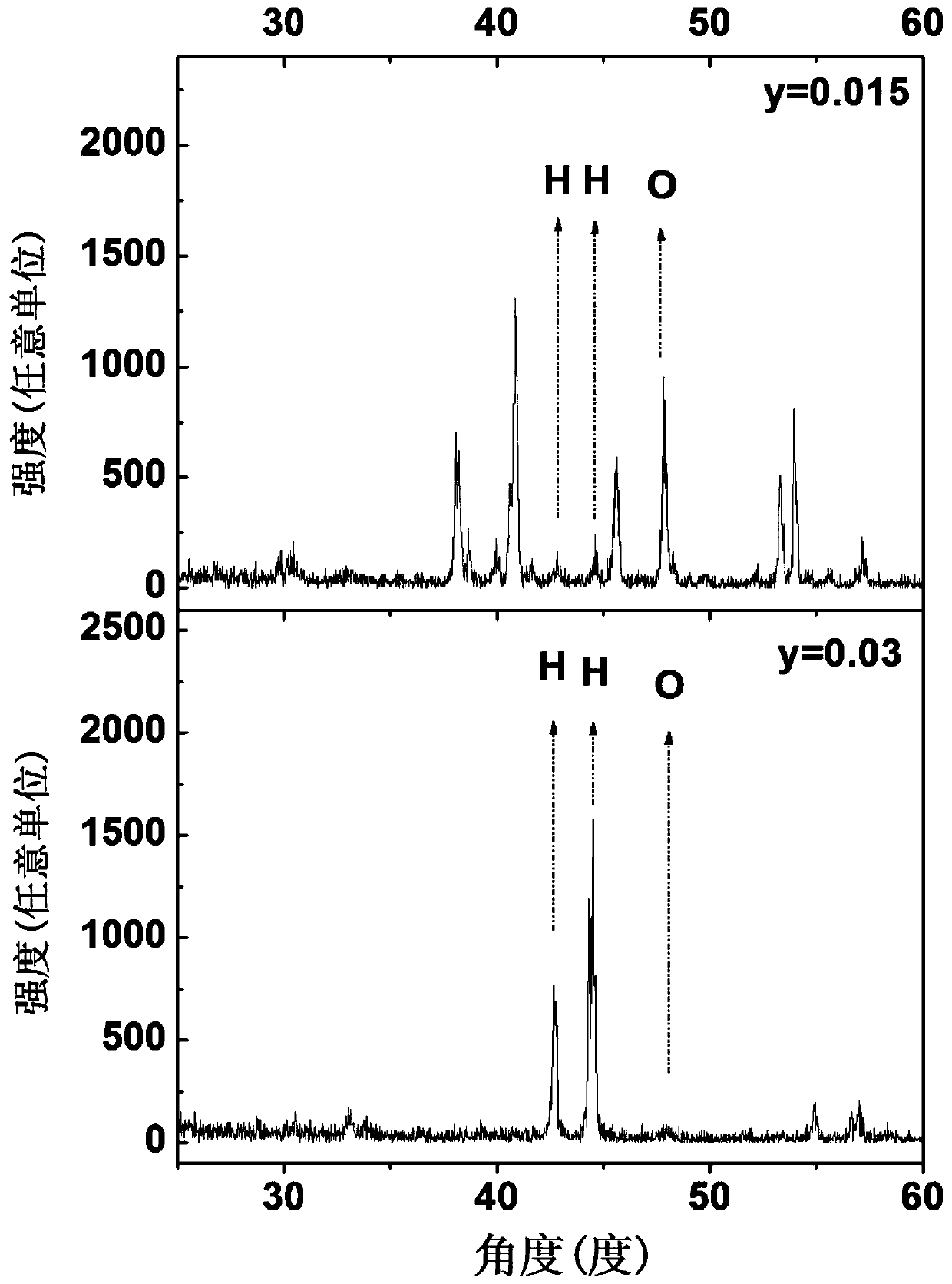

[0072] The composition of MnCoGe-based materials: MnCo 1-y In y Ge (y = 0.015, 0.03), the mass ratio of ball to material in step 4) is 5:1, the epoxy resin in step 5) is 10%, the curing agent ratio is 12%, and the pressing conditions in step 6) are: Apply 0.1 GPa pressure and press for 1 minute, and the curing conditions are: curing at 100°C for 2 hours.

Embodiment 3

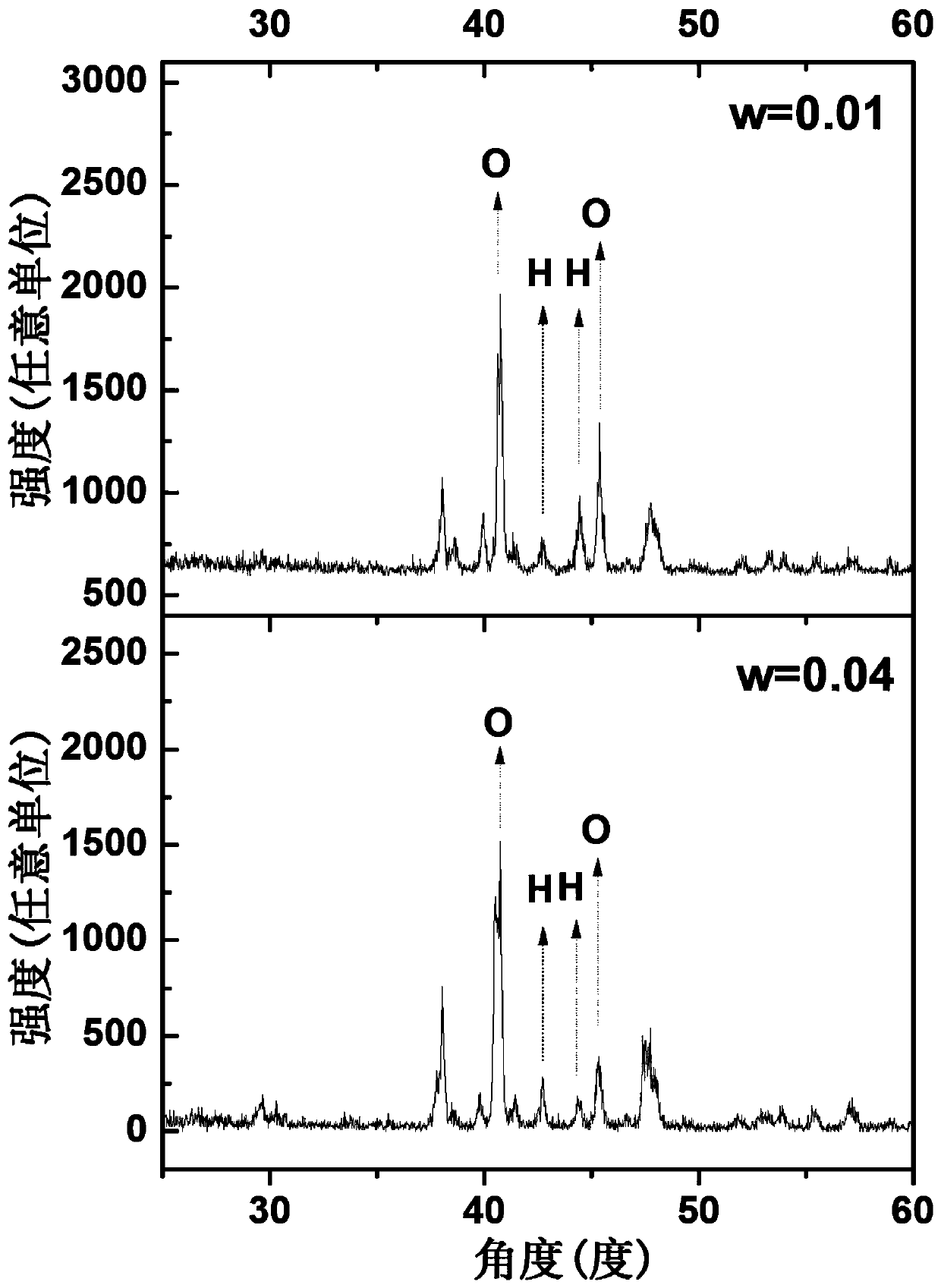

[0074] The composition of MnCoGe-based materials is: MnCoGe 1-z In z (z=0.01), the mass ratio of the ball material in step 4) is 10:1, the epoxy resin glue in step 5) is 4%, the curing agent ratio is 12%, and the pressing conditions in step 6) are: 1.5 GPa applied The pressure, pressing for 20 minutes, and the curing conditions are: curing at 170°C for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com