Method for detecting grouting fullness of prestressed duct of bridge

A channel grouting and detection method technology, which is applied in the direction of elastic testing, machine/structural component testing, measuring devices, etc., can solve problems such as unfavorable stethoscope receiving signals, prestressed channel grouting is not dense, shock echo weakening, etc. , to achieve broad implementation prospects, improve accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

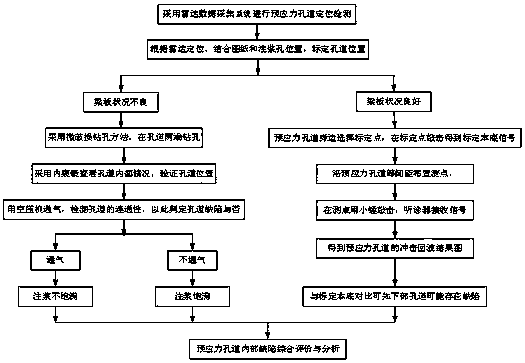

Method used

Image

Examples

Embodiment 1

[0018] The bridge structure in a certain area is a prestressed concrete cable-stayed bridge with double single towers, equal span and single cable plane. The bridge span structure is north-south symmetric, and the two links are independent. system, the aperture combination of the single bridge span structure is 72m+80m+168m+168m+80m+72m. The detection range is: 50 m in the mid-span area of 68 m, and 30 m in the mid-span area of 72 m (80 m).

[0019] In this embodiment, a middle room with a range of 30 meters in the span of 72 meters is selected for detection. Among them, there are 13 longitudinal prestressed pipes on the floor of the middle chamber, and the detection length is 195m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com