Defect detection method for industrial ray weld joint image

A defect detection and image technology, applied in the field of defect detection for industrial ray weld images, to achieve strong adaptability, improve accuracy, and reduce detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

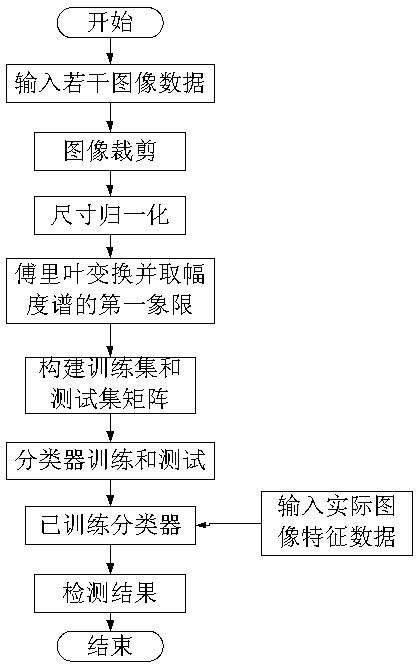

[0018] Example figure 1 As shown, the defect detection method of the present invention for industrial ray weld image comprises the following steps:

[0019] Step 1, select a number of weld seam image data taken by the X-ray machine, and perform preprocessing including image cropping and size normalization on the weld seam image data;

[0020] Step 2. Perform Fourier transform on the preprocessed weld image data to obtain its amplitude spectrum. According to the conjugate property of Fourier transform, take the first quadrant of the Fourier transform amplitude spectrum as the image feature data. Usually the image The feature data includes rows 1-64 and columns 102-200 in the image matrix;

[0021] Step 3: Make defect image marks and normal image marks on the image feature data respectively and form all samples, randomly select a part from all samples to form a training set matrix, and the rest form a test set matrix;

[0022] Step 4: Input the training set matrix into the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com