Functional material prepared from copper flotation tailings and preparation technology of functional material

A technology of functional materials and tailings, which is applied in the field of comprehensive utilization of solid waste resources, can solve the problems of low utilization of resources and difficult disposal of copper tailings, and achieve the effect of increasing specific surface area and porosity, and improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

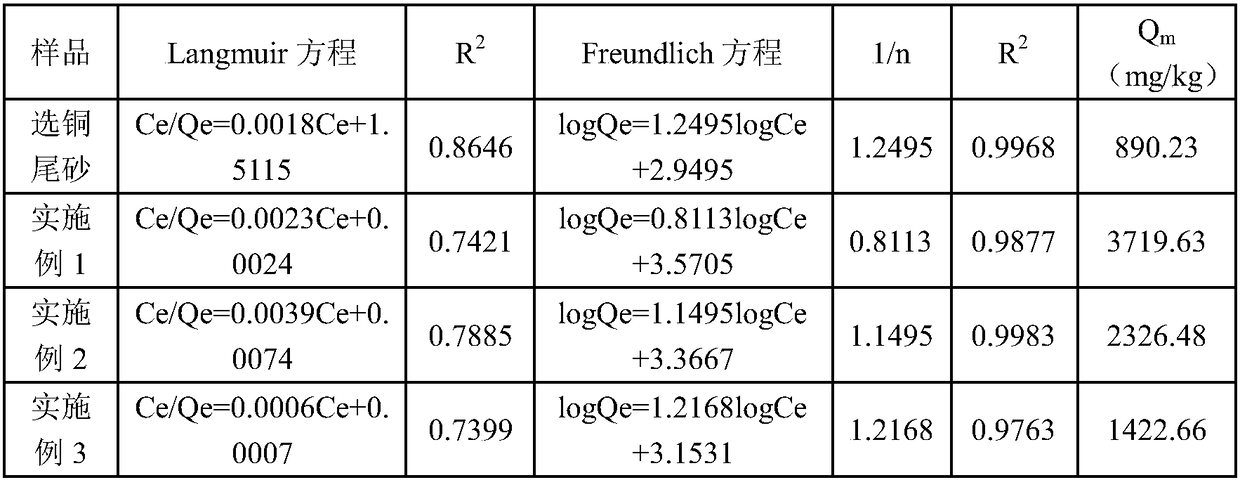

Examples

Embodiment 1

[0018] A process for preparing functional materials using copper-selected tailings, comprising the steps of:

[0019] A certain amount of copper tailings was taken, and the particle size was screened by cyclone classification. By adjusting the working parameters of the hydrocyclone classifier, the proportion of particles below 37 μm in the copper tailings accounted for 89%. Take 10g of fine-grained copper tailings after cyclone classification, add it to 150mL NaoH solution of 1mol / L, stir well, filter and wash until the eluate is neutral, and dry. Disperse the fine-grained copper tailings after surface activation by alkali treatment in 100mL deionized water, stir well and slowly add a certain amount of La(NO 3 ) 3 ·6H 2 The isopropanol solution with O content (with the addition ratio of fine-grained copper tailings after alkali treatment and surface activation is 5mmol / g), vigorously stirred to obtain a uniform mixed solution; add 1mol / L NaOH solution until the mixed solutio...

Embodiment 2

[0021] A process for preparing functional materials using copper-selected tailings, comprising the steps of:

[0022] A certain amount of copper tailings is taken, and the particle size is screened by cyclone classification, and the proportion of particles below 37 μm in the copper tailings is controlled to be 100% by adjusting the working parameters of the hydrocyclone classifier. Take 10g of fine-grained copper tailings after cyclone classification, add it to 150mL of 1mol / L HCl solution, stir well, filter and wash until the eluate is neutral, and dry. Disperse the fine-grained copper tailings after acid treatment and surface activation in 100mL deionized water, stir well and slowly add a certain amount of La(NO 3 ) 3 ·6H 2 Isopropanol solution with O content (with the addition ratio of fine-grained copper tailings after acid treatment and surface activation is 10mmol / g), stir vigorously to obtain a uniform mixed solution; add 1mol / L NaOH solution until the mixed solution ...

Embodiment 3

[0024] A process for preparing functional materials using copper-selected tailings, comprising the steps of:

[0025] A certain amount of copper tailings is taken, and the particle size is screened by cyclone classification, and the proportion of particles below 37 μm in the copper tailings is controlled to 85% by adjusting the working parameters of the hydrocyclone classifier. Take 10g of fine-grained copper tailings after cyclone classification, add it to 150mL NaOH solution of 1mol / L, stir well, filter and wash with water until the eluate is neutral, and dry. Disperse the fine-grained copper tailings after surface activation by alkali treatment in 100mL deionized water, stir well and slowly add a certain amount of La(NO 3 ) 3 ·6H 2 The isopropanol solution with O content (with the addition ratio of fine-grained copper tailings after alkali treatment and surface activation is 0.5mmol / g), vigorously stirred to obtain a uniform mixed solution; add 1mol / L NaOH solution until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com