Enhanced diffusion-type photocatalyst atomizer

A photocatalyst and atomizer technology, applied in the field of photocatalyst, can solve the problems of poor photocatalyst diffusion ability, small diffusion range and insufficient diffusion, and achieve the effect of wide range, strong diffusion ability and uniform diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

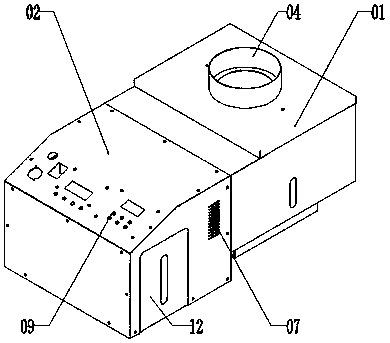

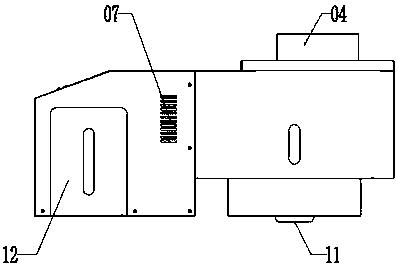

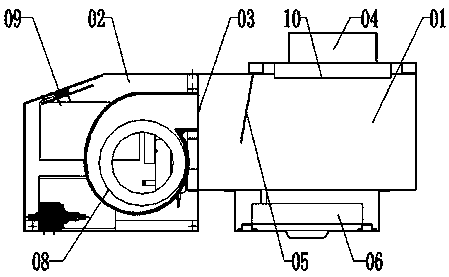

[0029] like Figure 1-4, an enhanced diffusion photocatalyst atomizer, which includes a photocatalyst drug box 01 and an electrical control box 02, the photocatalyst drug box 01 is a sealed box, and an air inlet 03 is arranged on the side wall of the box. Smoke outlet 04 is set on the top, and stainless steel tubes are set on the bottom of the box. Both ends of the stainless steel tubes pass through the side wall of the box and extend into the electrical control box 02. There is an inclined baffle 05 inside the box, and the top of the baffle 05 is fixedly connected to the top of the box. , the bottom is inclined towards the air inlet side, the baffle plate 05 is facing the air inlet 03, there is a gap between the baffle plate 05 and the two side walls of the box, and the bottom of the box is also provided with an ultrasonic generator 06; The side wall of the electrical control box 02 is provided with a ventilation hole 07, and the electrical control box 02 is provided with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com