Novel laser cutting robot device

A laser cutting and robot technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of hidden safety hazards, exposed power supply sheets, difficult disassembly and assembly, etc., and achieves the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

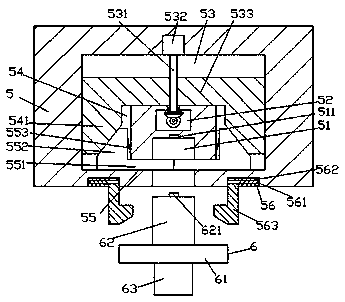

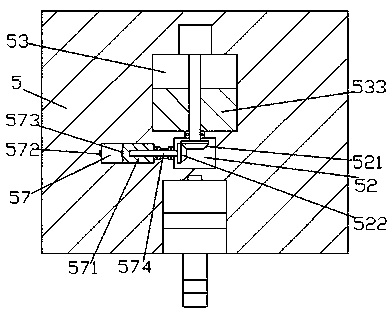

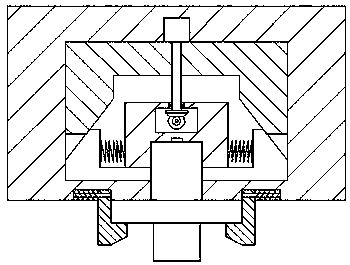

[0016] Combine below Figure 1-5 The present invention will be described in detail.

[0017] refer to Figure 1-5 , according to an embodiment of the present invention, a new type of laser cutting robot device, including a plurality of sets of power transmission elements 5 fixedly installed in the front end surface of the power transmission main frame 4 and plugs for mating connection with the power transmission elements 5 Connecting element 6, the base 3 is fixedly installed on the bottom end surface of the main transmission main frame 4, and the bottom end surface of the base 3 is fitted with a rolling wheel 31, and the bottom end surface of the transmission element 5 is provided with an insertion connection groove 51. A first slot 52 is provided inside the conduction element 5 on the upper side of the plug-in slot 51 , and a first slide that expands left and right is provided inside the conduction element 5 on the upper side of the first hole 52 . Groove 53, the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com