Sliding wheel component and numerical control machine tool pull hood adopting sliding wheel component

A pulley assembly, CNC machine tool technology, used in maintenance and safety accessories, metal processing mechanical parts, metal processing equipment, etc., can solve the problem of the tool rest not working normally, detaching from the guide rail, etc., to ensure the processing efficiency and ability, and smooth operation. , the effect of not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

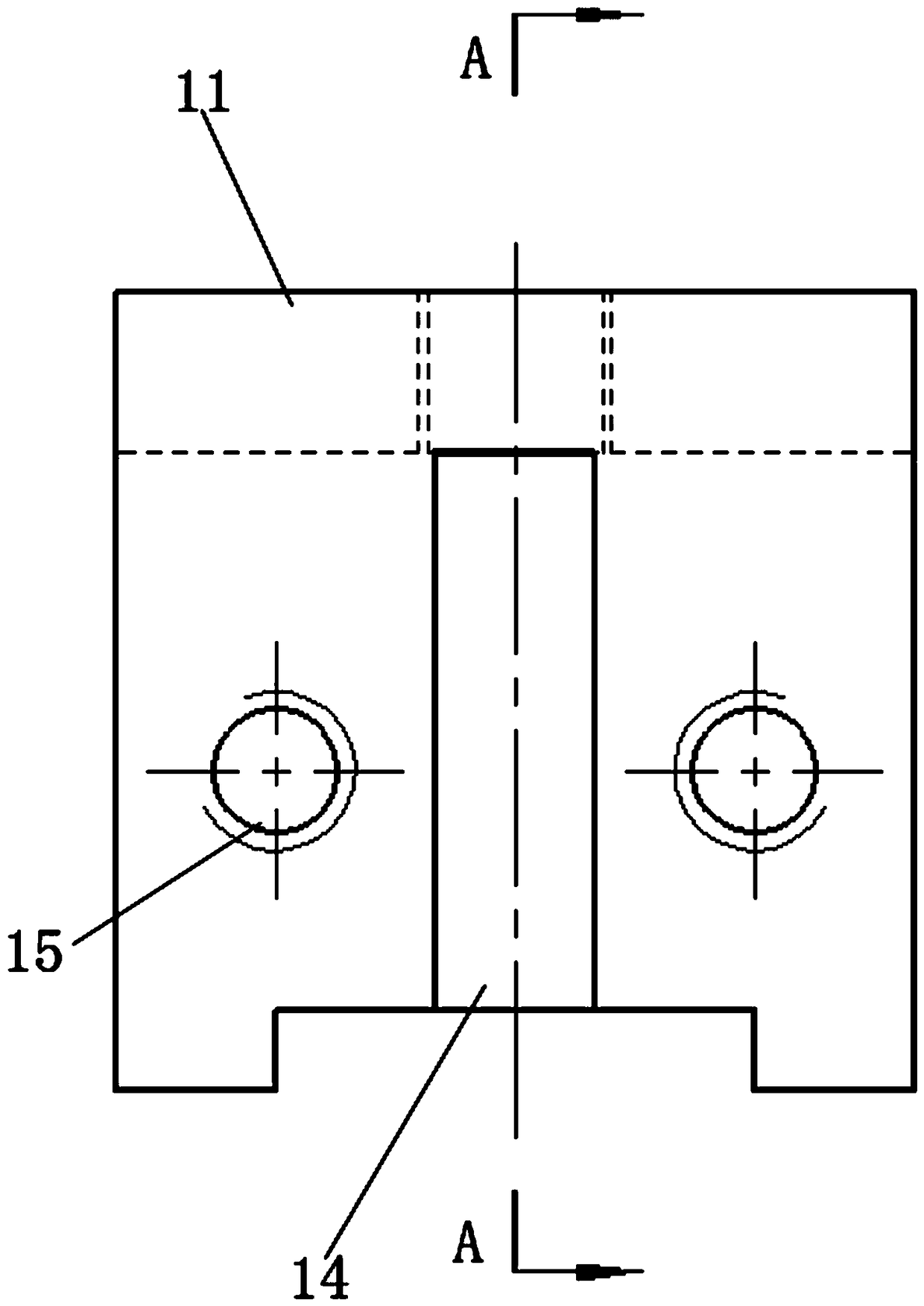

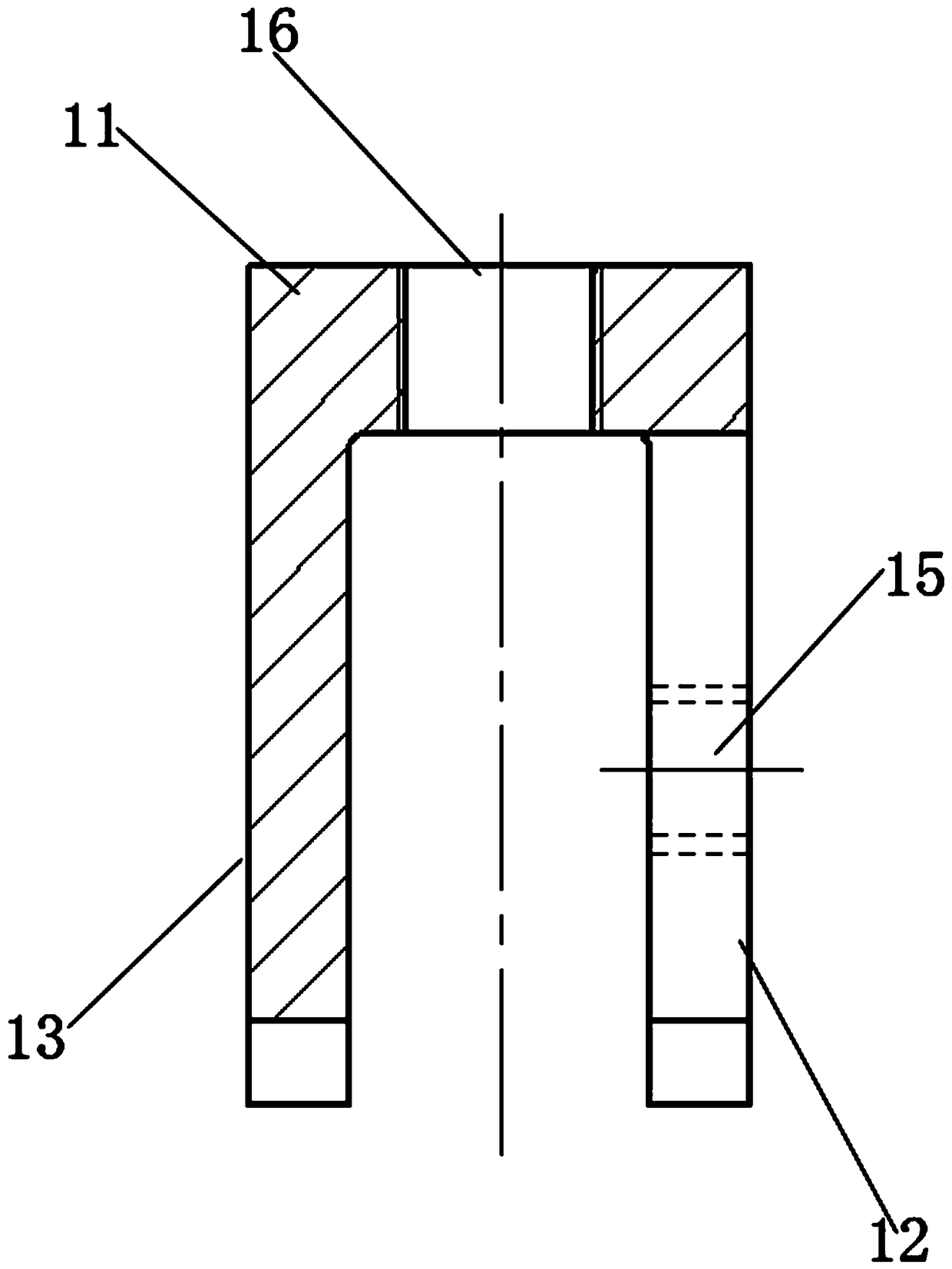

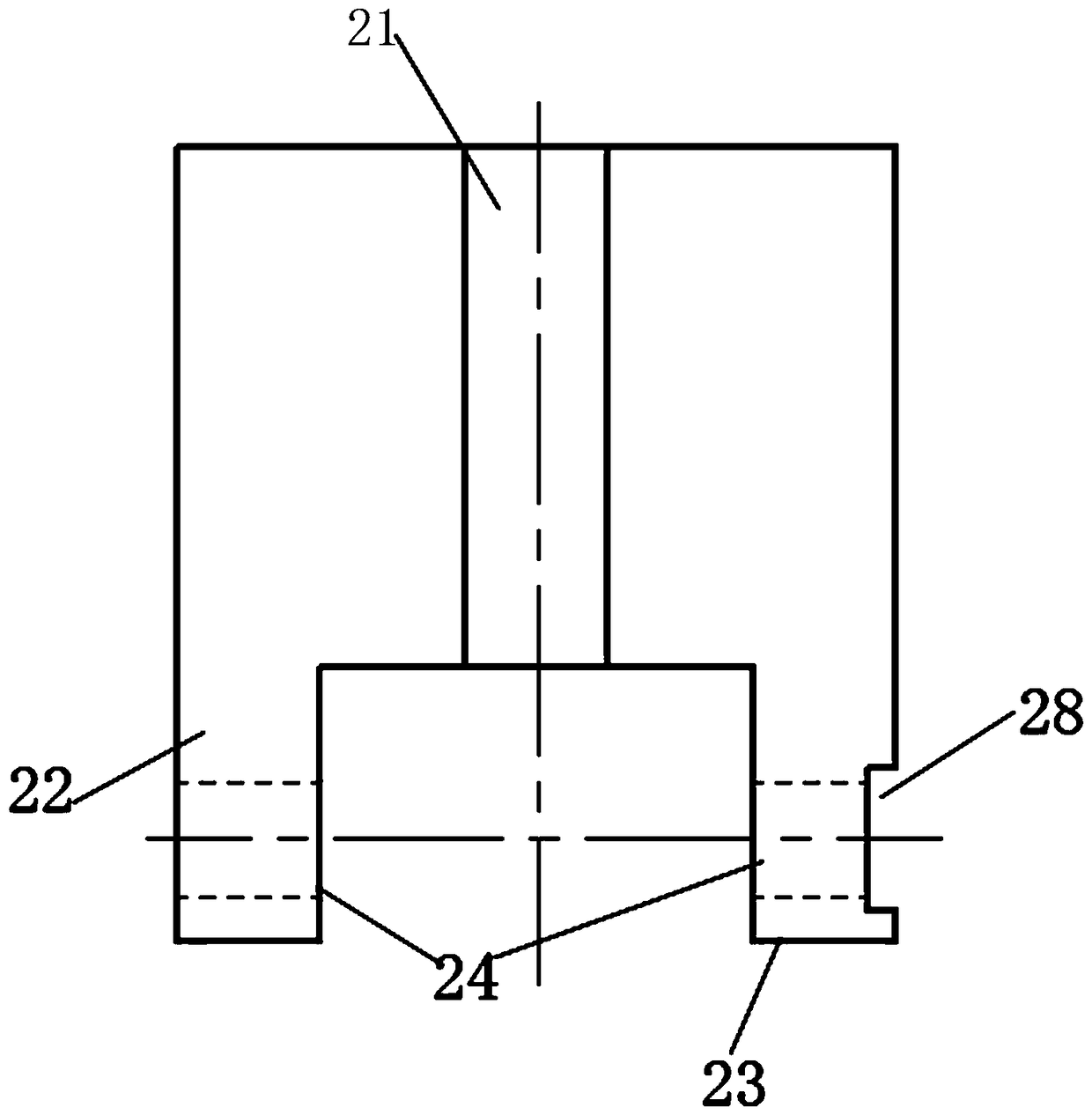

[0042] A pulley assembly, including a fixed block 1 and a slider 2; the fixed block 1 includes a rectangular base 11, and the front and rear parts of the bottom of the base 11 respectively extend downwards against the front and rear sides of the bottom to form front and rear extensions 12, 13; where the middle of the front extension section 12 is downwardly opened with a limit vertical groove 14 which divides the front extension section 12 into left and right parts by the bottom surface of the base 11; Through screw holes 15; the center of the base 11 has a threaded hole 16 through up and down; the slider 2 comprises a cuboid structure, and the middle part of the front side of the cuboid structure is provided with a vertical protrusion matched with the limit vertical groove 14. 21, the slide block 2 is inserted into the long groove formed between the front and rear extension sections 12, 13 of the fixed block and the vertical protrusion 21 is located in the limit vertical groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com