Device and method for monitoring tool state in cutting process and chip formation

A cutting tool technology, which is applied in the field of monitoring tool status in cutting processing and chip formation, can solve the problems of affecting the acquisition accuracy of AE sensors, distortion of monitoring system monitoring functions, narrow application range, etc., and achieves strong correlation and independence Good performance and guaranteed collection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

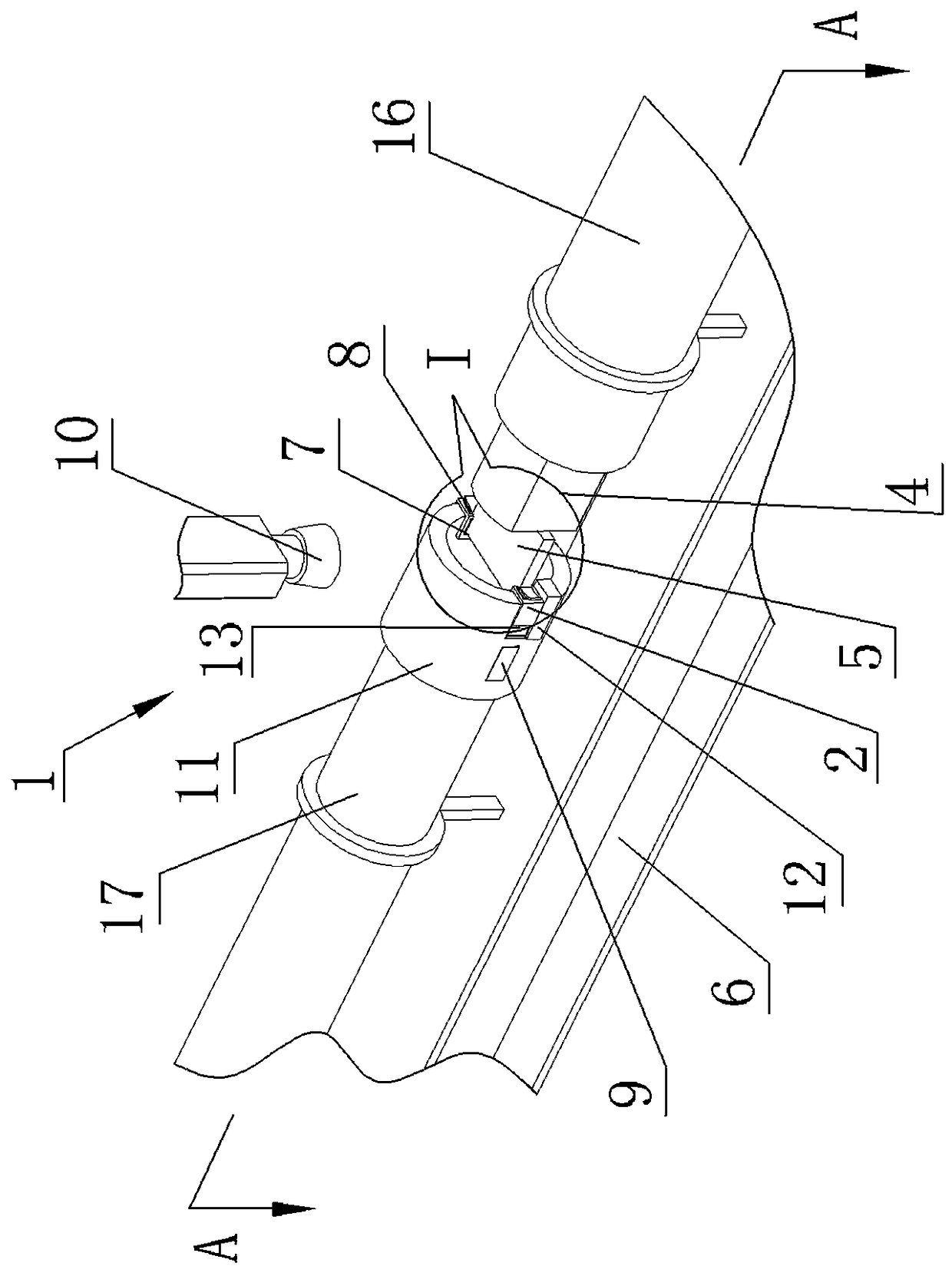

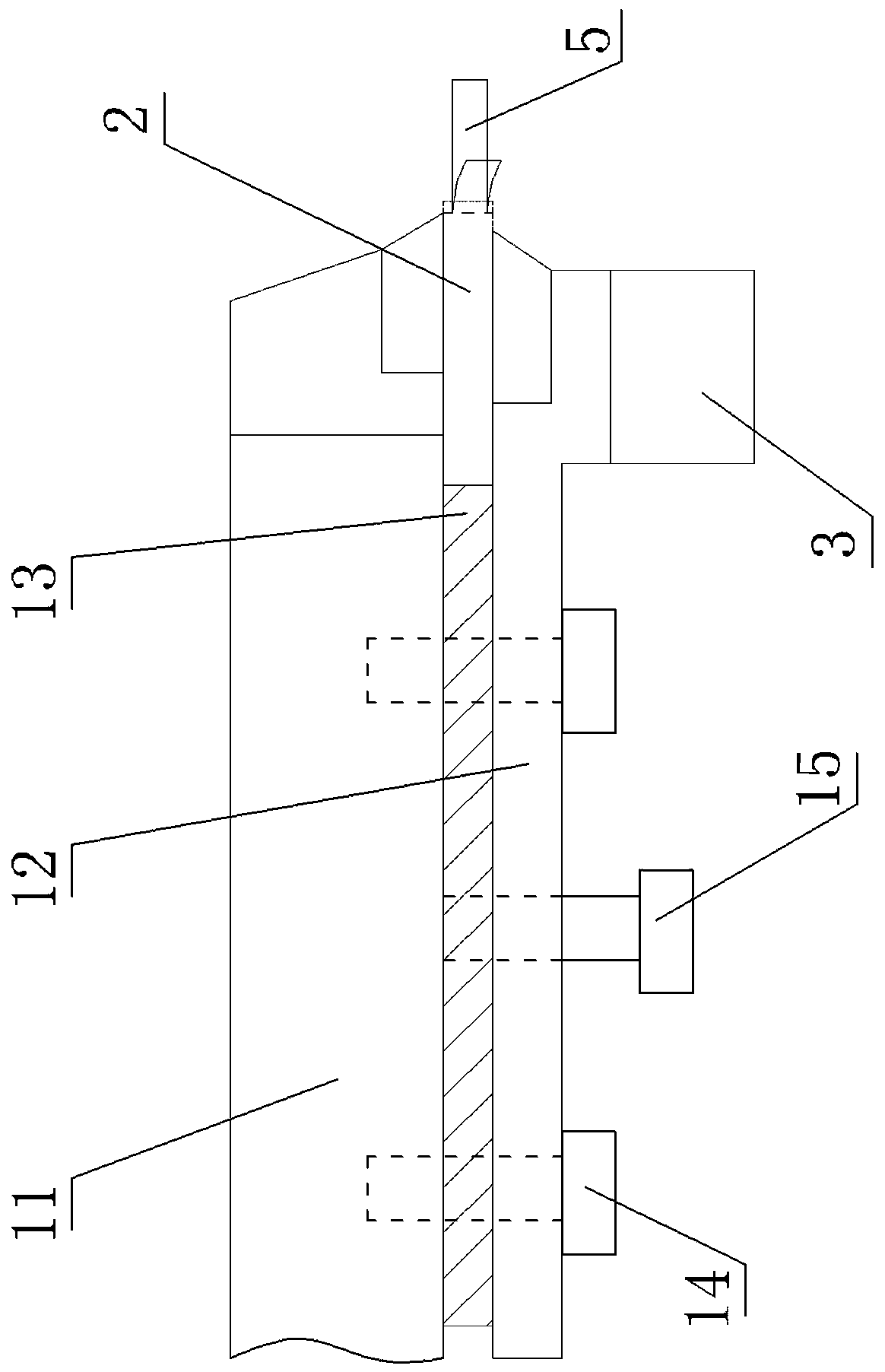

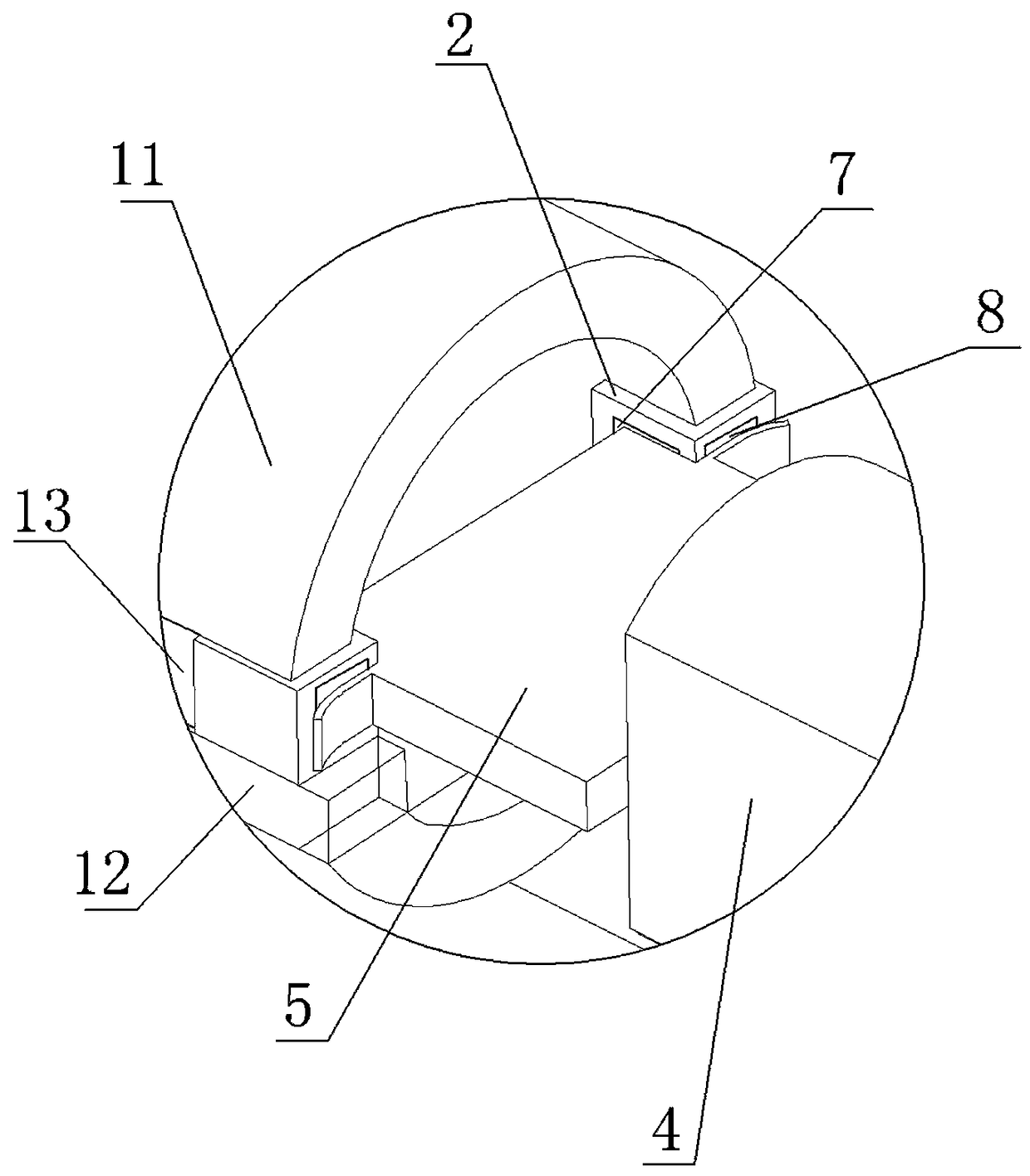

[0035] From Figure 1 to Figure 3 It can be seen that the device for monitoring the cutting tool state in the cutting process and chip formation of the present invention includes a tool holder 1, a tool 2, an AE signal collector 3, a fixture 4, a workpiece 5, a test platform 6, a piezoelectric force Sensor one 7, piezoelectric force sensor two 8, surface strain gauge 9, high-speed CCD camera 10 and a data acquisition system for signal acquisition and storage, wherein

[0036] The tool holder 1 includes a main holder 11, a secondary holder 12, a heat insulation and vibration damping pad 13, several connecting bolts 14 and a number of adjustment bolts 15, and the cutter 2 and the heat insulation and vibration damping pad 13 are arranged side by side on the main holder 11. Between the auxiliary holder 12, the thread on the connecting bolt 14 rotates in the forward direction, and the thread on the adjusting bolt 15 rotates in the reverse direction. The holder 11 is threaded, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com