A method for preparing high-density hafnium diboride ceramics

A hafnium diboride and densification technology is applied in the field of preparing high-density hafnium diboride ceramics and high-density hafnium diboride ceramics, and can solve the problems of difficulty in densification, difficulty in preparing pure phases into blocks, and the like, Achieve high density, easy promotion and large-scale production, high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

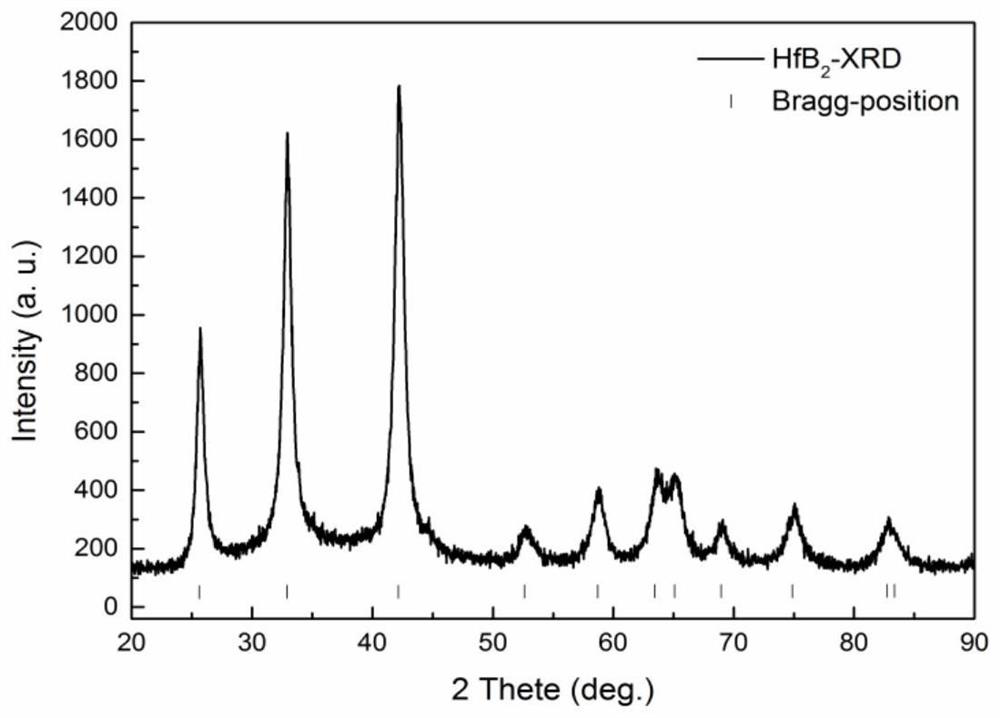

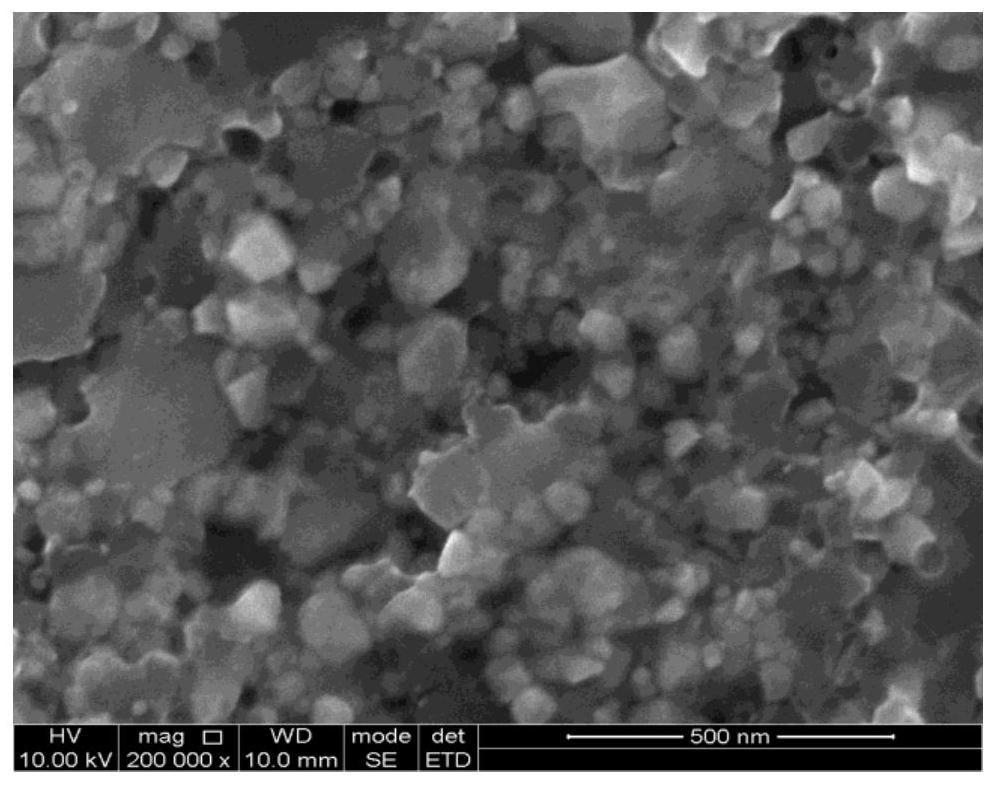

Image

Examples

Embodiment

[0031] A method for preparing high-density hafnium diboride ceramics, comprising the following steps:

[0032] (1): Using hexagonal structure hafnium diboride powder as raw material;

[0033] (2): The raw materials obtained in step (1) are subjected to high-energy ball milling, with n-hexane as the process control agent and high-speed steel balls as the grinding balls, and the process control agent, grinding balls, and hafnium diboride raw materials according to the ratio of 4:9: After being mixed at a weight ratio of 1, place in a high-energy ball mill and carry out ball milling at a speed of 320r / min for 45 hours;

[0034] (3): Pickling the raw materials after ball milling in step (2), using aqua regia for pickling;

[0035] (4): The raw material after pickling in step (3) is heated at a temperature of 800°C and a vacuum of 1×10 -2 Under the condition of Pa, carry out high-temperature vacuum treatment for 60 minutes, then use molybdenum, tantalum, niobium, and platinum to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com