A kind of multi-layer composite large-scale plastic inspection well chamber and preparation method thereof

A plastic inspection well and composite technology, which is used in construction, artificial island, infrastructure engineering, etc., can solve the problems of complicated pressing mechanism and device, high mold design and manufacturing cost, large size of large plastic inspection well, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

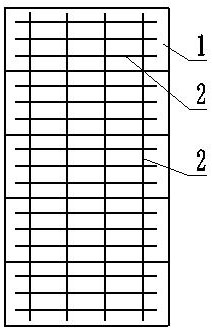

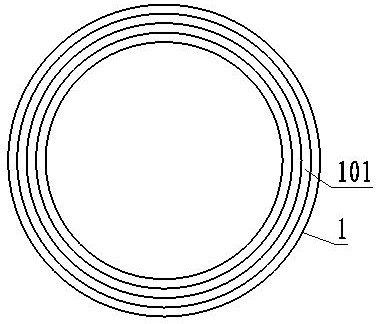

[0037] Embodiment 1: refer to Figure 1 to Figure 2It can be seen that a multi-layer composite large-scale plastic inspection well chamber includes a single-section well chamber 1 and a stiffener plate 2. The single-section well chamber 1 is set together by four cylindrical parts 101 and welded by laser transmission. Made, welding is convenient and firm. The single-section well chamber 1 is provided with five pieces, and the five pieces of the single-section well chamber 1 are sequentially welded together by coaxial laser transmission from top to bottom to form an integral well chamber. The horizontal and vertical sides of the outer wall of the well are respectively Uniform laser transmission welding with multiple stiffener plates 2 .

[0038] The thickness of the cylindrical parts 101 is 2.4 mm, the height is 500 mm, and the diameter is 1500-2000 mm. The gap between the circumferential surfaces of the cylindrical parts 101 is 0.1 mm, which facilitates the assembly of the cyl...

Embodiment 2

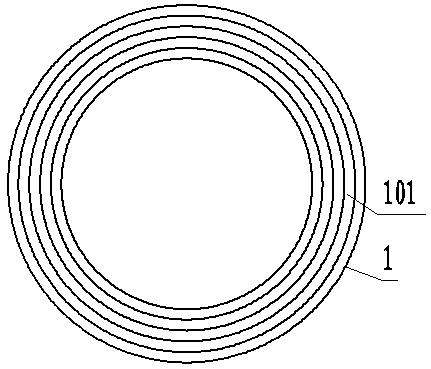

[0051] Embodiment 2: refer to figure 1 , image 3 It can be seen that a multi-layer composite large-scale plastic inspection well chamber includes a single-section well chamber 1 and a stiffener plate 2. The single-section well chamber 1 is set together by five cylindrical parts 101 and welded by laser transmission. Made, welding is convenient and firm. The single-section well chamber 1 is provided with five pieces, and the five pieces of the single-section well chamber 1 are sequentially welded together by coaxial laser transmission from top to bottom to form an integral well chamber. The horizontal and vertical sides of the outer wall of the well are respectively Uniform laser transmission welding with multiple stiffener plates 2 .

[0052] The cylindrical parts 101 have a thickness of 3 mm, a height of 500 mm, and a diameter of 1500-2000 mm. The gap between the circumferential surfaces of the cylindrical parts 101 is 0.25 mm, which facilitates the assembly of the cylindri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com