Universal-type wide energy rotary jetting engine

A general-purpose engine technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of low engine thermal efficiency, narrow use of energy, high vibration and noise, etc., and achieve low noise, easy maintenance, and operation no vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

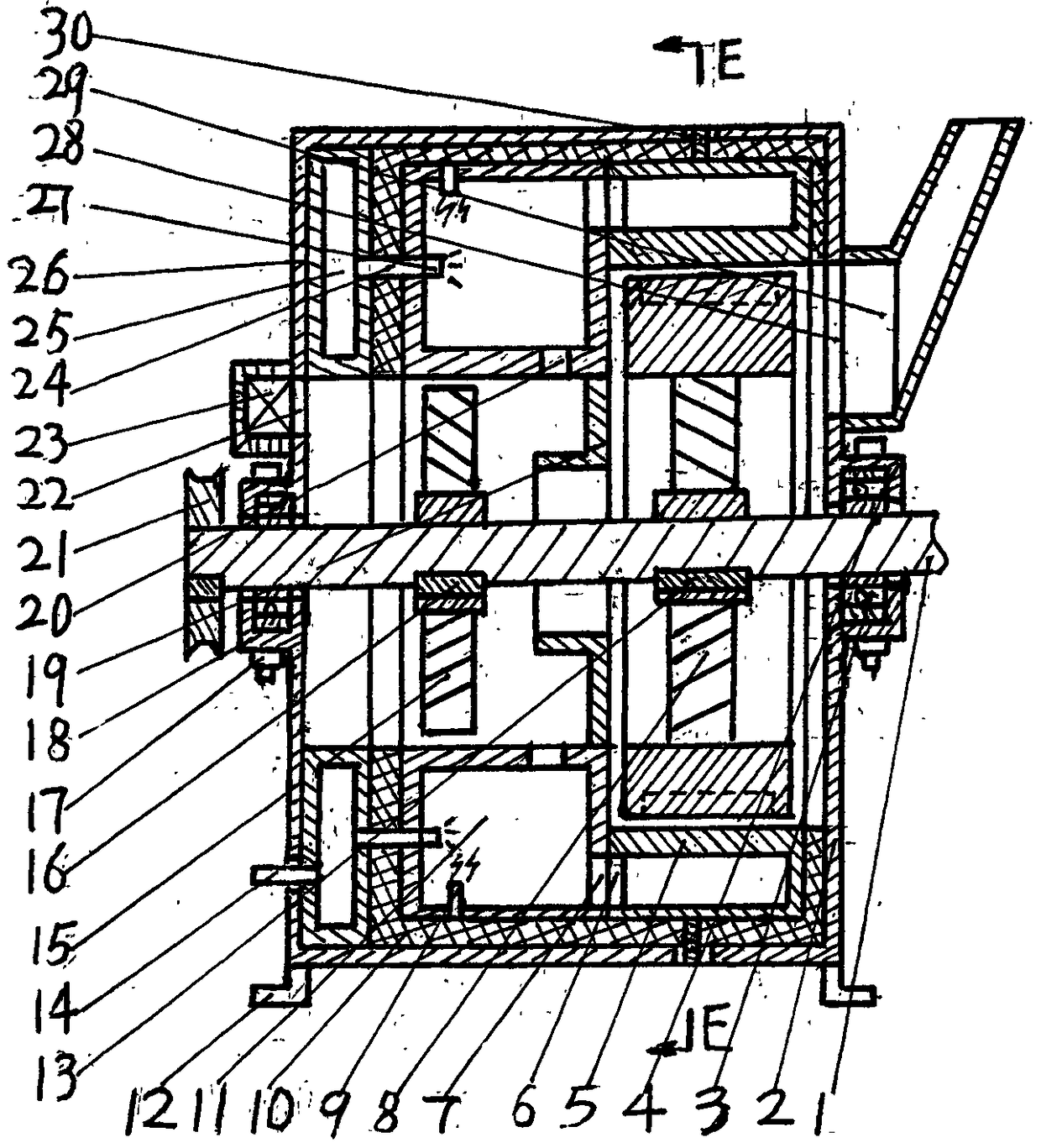

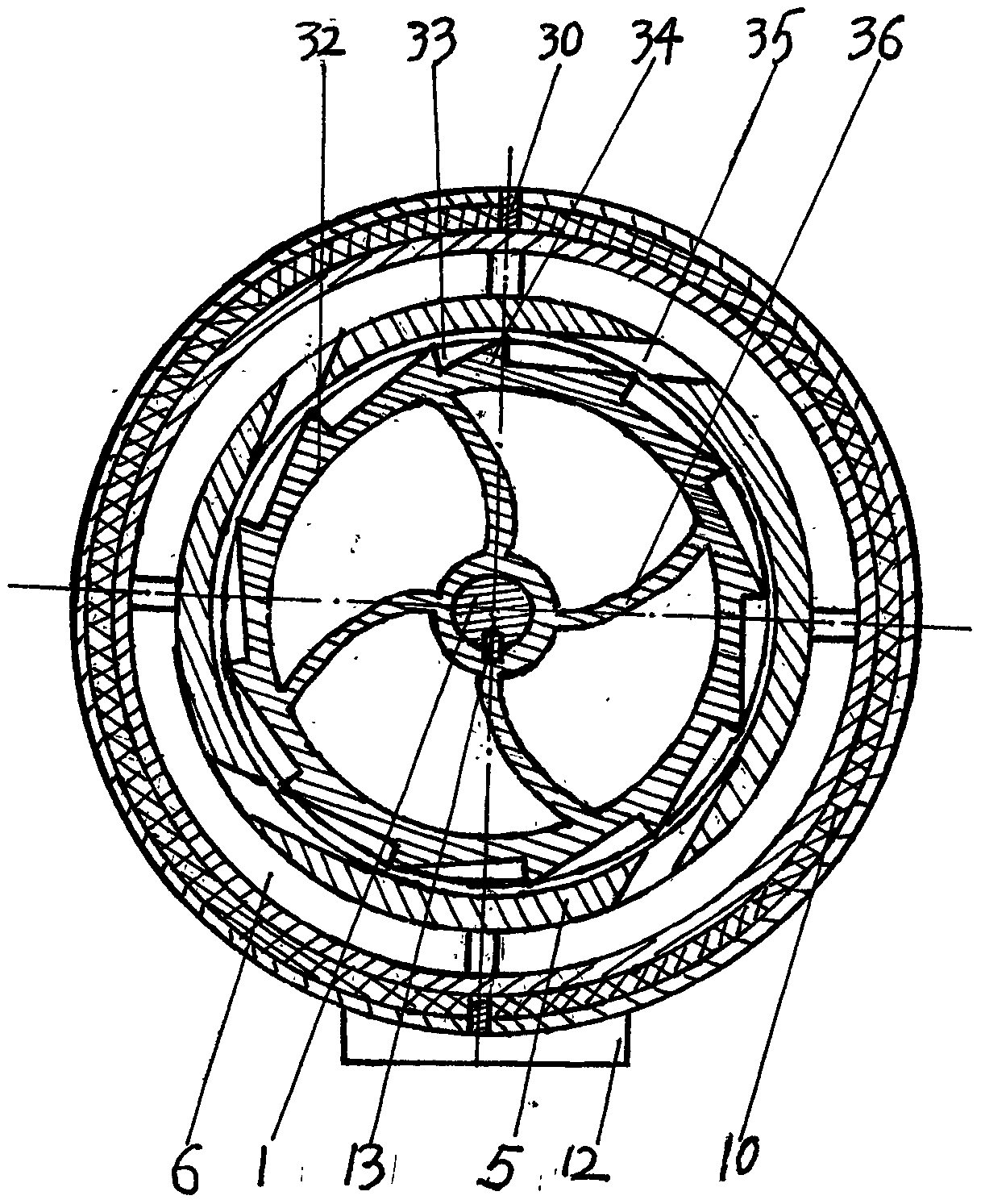

[0035] Such as figure 1 As shown, the general-purpose wide-energy jet engine includes a main shaft 1, a bearing 3, a fuel injection device 23, an ignition device 9, an air filter device 23, an intake turbocharger 15, etc., and other auxiliary components, with an exhaust outlet 28 , the air intake window 22 and the upper housing 26 of the upper bearing sleeve 4, etc., and the lower housing 2 with the support fixing seat 12, the lower bearing sleeve 18, etc. are connected and closed by the connecting bolts 17 to form a complete housing together, and the inside of the housing is closed. Enclosed to form a relatively closed hollow cylindrical inner space; the upper and lower shell bearing sleeves 4 and 18 are butted and closed together to form a complete bearing sleeve, and the two bearings 3 installed on the main shaft 1 are respectively fixed and installed in these two complete bearing sleeves. In the bearing sleeve; in the complete internal space of the shell, around the main s...

Embodiment 2

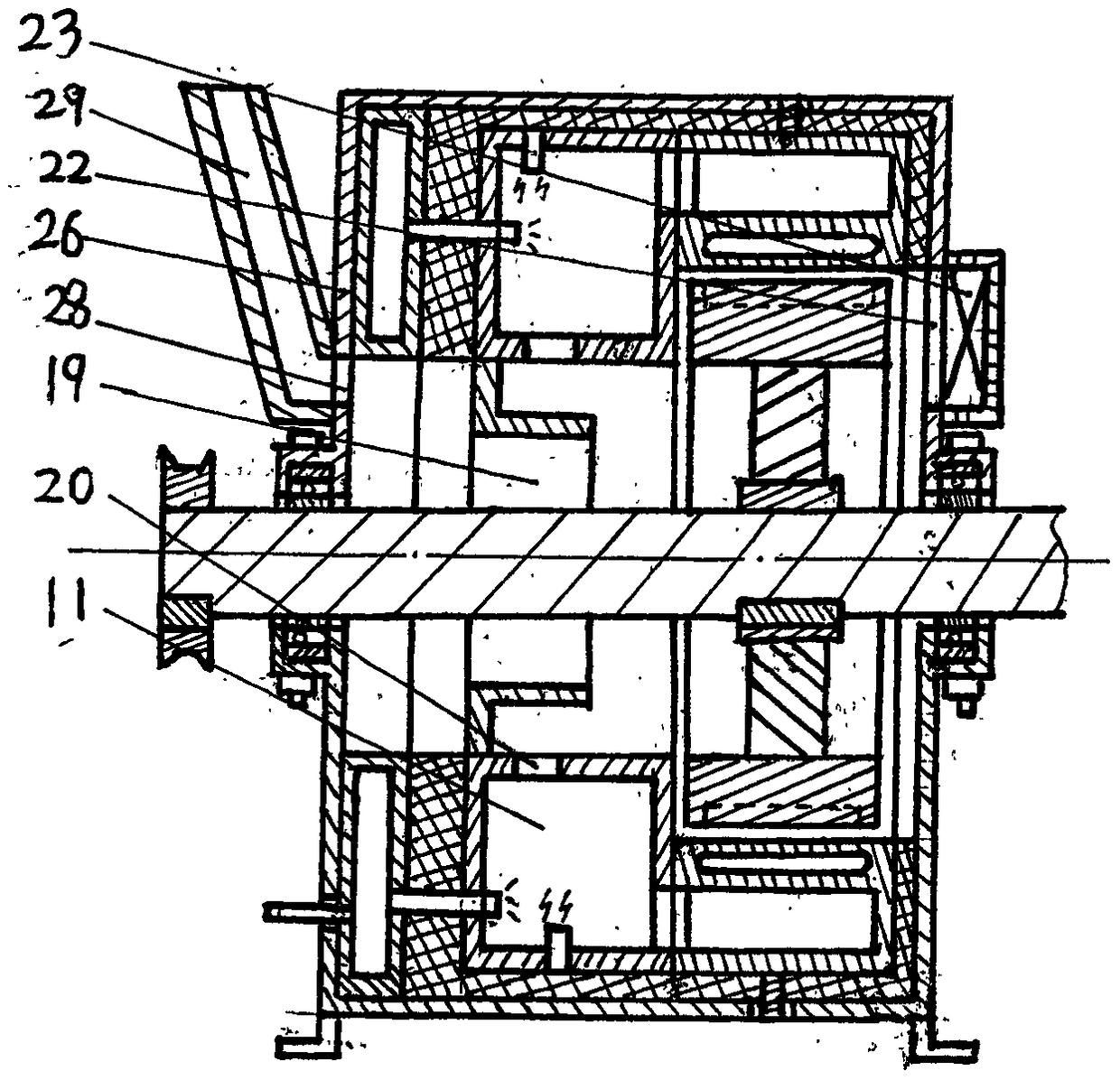

[0037] Such as figure 2As shown, another specific embodiment of the present invention can be completed by making the following changes to the specific embodiment of Embodiment 1: remove the intake turbocharger 15 and its fixed key 16; change the installation position of the intake adjustment plate, and the The annular disk of the air regulating plate 19 is fixedly connected with the outer surface of the inner ring cylindrical surface under the end face of the annular combustion chamber 11 where the fuel pressure stabilizing ring 25 abuts, and the cylinder on the air intake regulating plate 19 extends into the annular combustion chamber 11 In the ring cylinder; the air inlet 20 on the side wall of the ring cylinder of the annular combustion chamber 11 is close to the annular disc part of the air intake adjustment plate 19; the tail gas outlet 28 and the air inlet window 22 in the embodiment 1 The positions are exchanged, and the layout and arrangement of other components are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com