Piston-cylinder unit used for forming machine and forming machine

A cylinder unit, molding machine technology, applied in mechanical equipment, fluid pressure converter, fluid pressure actuating device, etc., to achieve the effect of simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

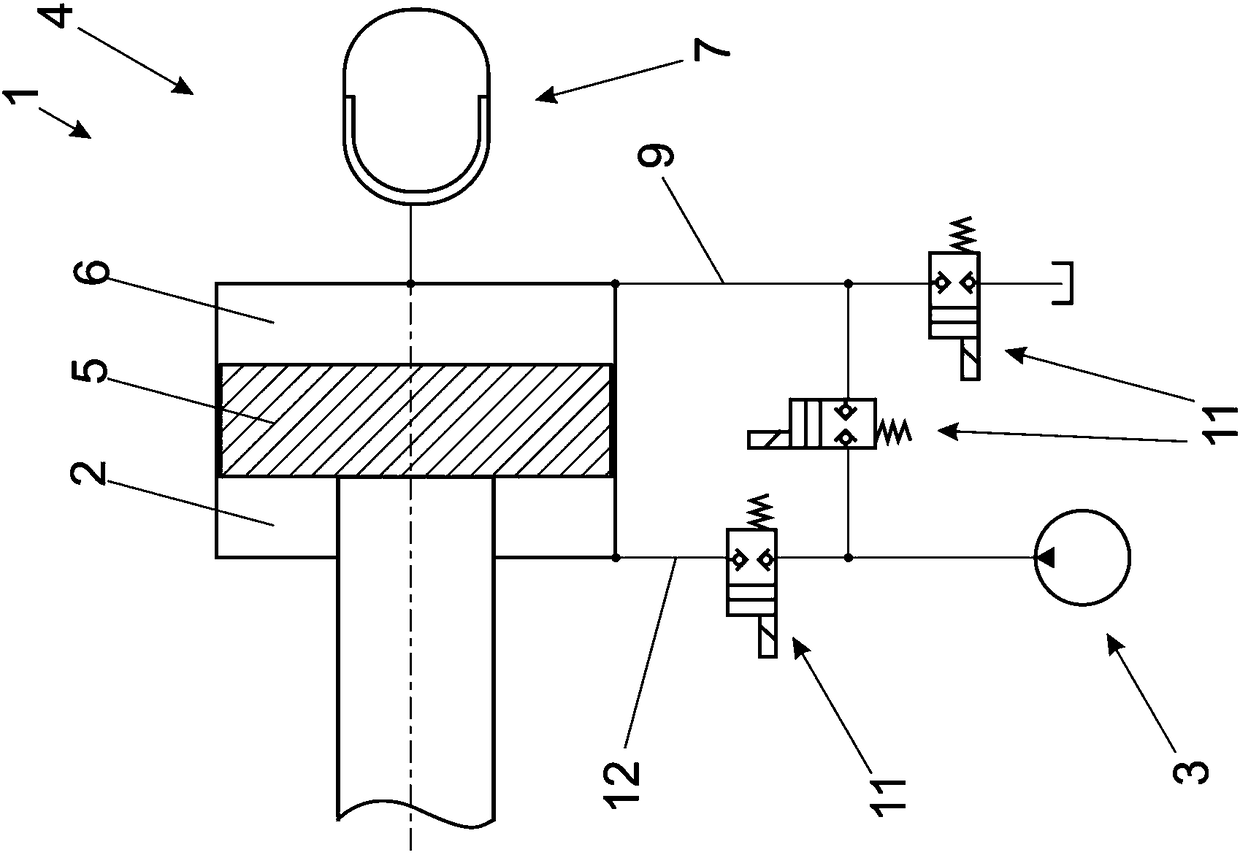

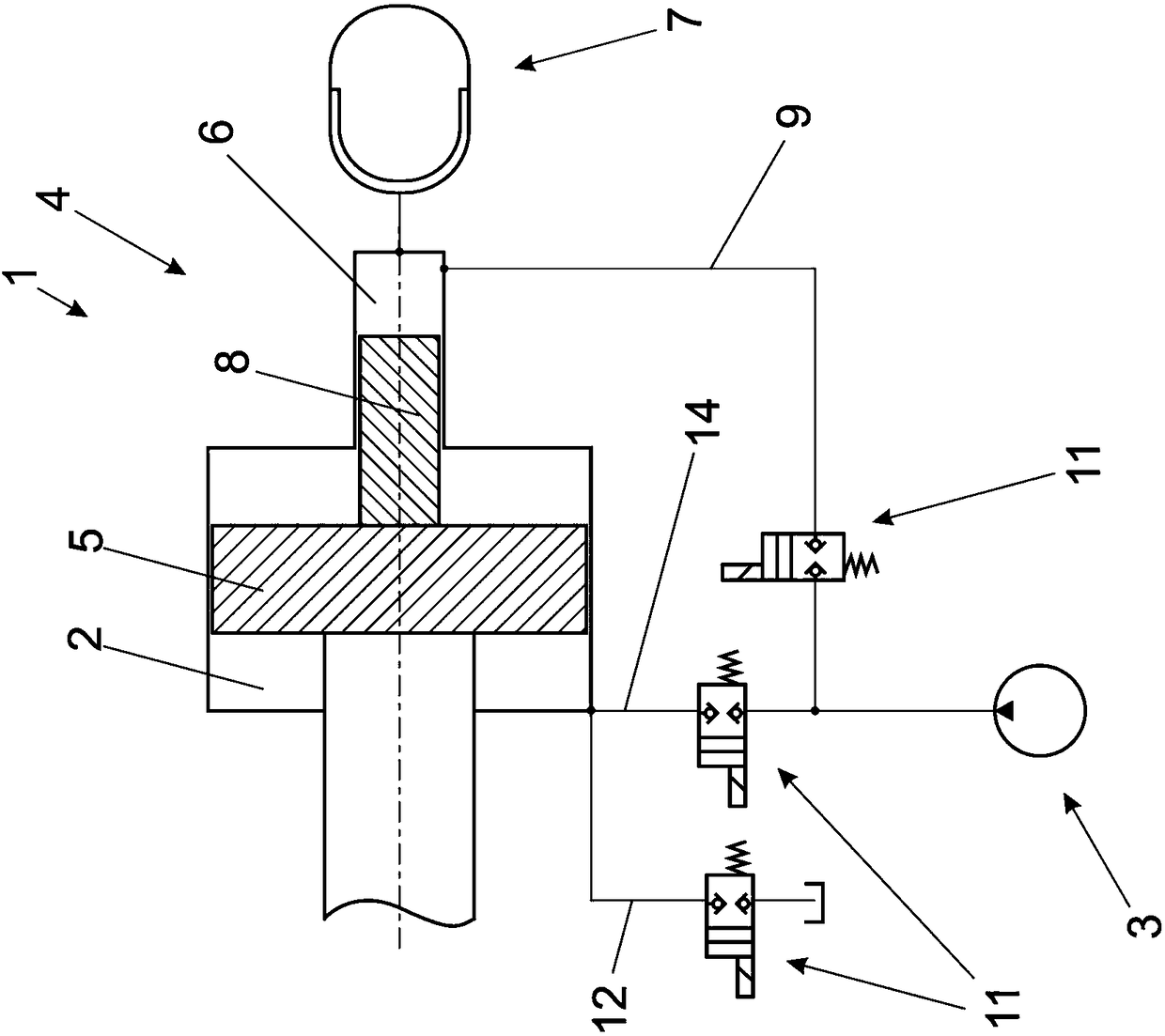

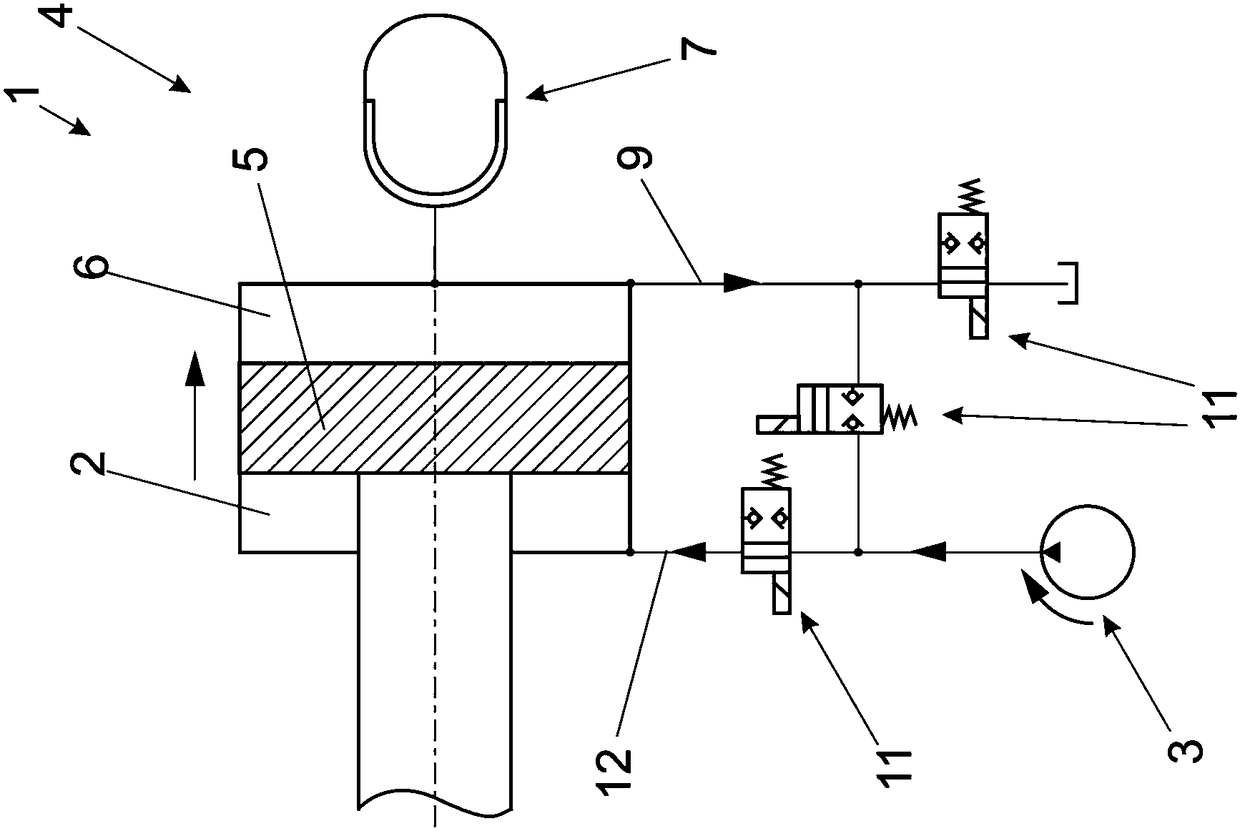

[0040] Figure 1a A piston-cylinder unit 1 according to the invention is shown with a first chamber 2 , a piston 5 and a second chamber 6 . The first chamber 2 on the shank side is used, for example, to act with clamping force in a clamping unit 15 of an injection molding machine. The first chamber 2 is connected to the pump 3 for this purpose. The second chamber 6 is then connected to the pressure accumulator 7 .

[0041] in press Figure 1a In the preferred embodiment, the discharge line 12 is at the same time the input line 14 to the first chamber 2 . A non-return valve 11 is also arranged in the discharge line 12 , and the second chamber 6 is also connected to the pump 3 in addition to the pressure accumulator 7 , ie via the connecting line 9 . A connection from the second chamber 6 to a tank (not referenced) for hydraulic fluid is also established via this connecting line 9 . Two check valves 11 are also located in the connecting line 9, one of which is used for the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com